Heating boilers: how to choose the right unit for efficient

In specialized stores engaged in the implementation of climate equipment, the choice of the consumer is represented by a huge number of devices, with the help of which the heating medium is heated for water heating networks. You can buy steel and cast iron heating boilers, gas and solid fuel, mounted and floor, classic and inverter.

And to understand all this diversity and make the right choice will help the instruction, which you can find below.

Gas: economy and automation

Gas-fired boilers for heating are most often used for the installation of autonomous heating engineering networks.

The principle of their operation is as simple as possible: when a command is received from a controller, a special igniter ignites the incoming gas and initiates the combustion process. The resulting thermal energy is transferred to the fluid circulating through the heat exchanger, which, in turn, flows through the pipes to the batteries, where the secondary heat exchange takes place - the air in the room is heated.

The main advantage is automation. Once you set up the operating modes with your own hands, you can forget about the existence of the boiler. A special controller independently controls the operating modes depending on the temperature inside and outside.

The German heating boilers based on Viessmann gas, as well as the Czech Protherm, have proven themselves to work well. However, and domestic equipment sold, for example, under. trademarks Conord or Mimax is not much different in functionality, and the price will pleasantly surprise any buyer.

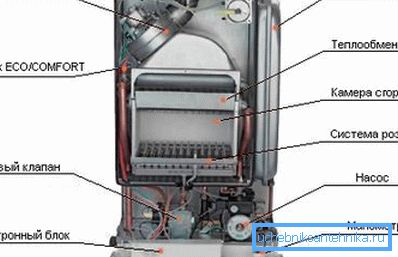

To organize boiler heating at home, besides the heater itself, you usually need to purchase and install a large number of other devices. This rule does not apply to modern boilers.

Everything you need is already part of the unit, which consists of the following main elements:

- gas burner;

- control automation;

- temperature sensors;

- expansion tank;

- circulation pump for heating.

As for the types of gas heaters, there is simply a huge range of devices on the market that can satisfy the needs of any customer.

All existing varieties are presented in more detail in the table.

| Variety | Description |

| With an open combustion chamber | The boiler for heating with an atmospheric burner, as a rule, is a fairly powerful and massive device. It must be installed in a separate room with intensive ventilation. Also required is a vertical pipe with a natural baffle, through which combustion products will be removed. |

| With hermetic combustion chamber | In this equipment case, the combustion reaction occurs in a heat exchanger insulated from the external environment. A turbine and a coaxial duct, which is mounted in the wall of a house, is used to inject air and remove the combustion products. Most often, this category includes compact units for city apartments and small houses. |

| With steel heat exchanger | Steel is used to construct the combustion chambers of these devices. Steel coppers differ in small weight and compact dimensions. However, durability suffers. |

| With cast iron heat exchanger | The cast-iron boiler is not hung on the wall, as it is produced in the floor version. Such devices are more durable and, as a rule, produce a greater amount of thermal energy. They are used for heating large houses. They are installed in separate boilers, where they occupy a fairly large space. |

| Single circuit | Boilers are used only for heating homes. If you need to prepare hot water for domestic needs, you will have to purchase and install additional equipment. |

| Double circuit | They cost more than single-circuit ones, but they have two coils, one of which is necessary for heating, and the second serves for heating hot water supplied to the bathroom and to the kitchen. |

| Hinged | This is the minimum size of the device, characterized by low power. They can be installed both in a separate room and in the kitchen, where there is access to a gas pipe and plumbing system. |

| Outdoor | Floor heating boiler is usually characterized by high power and is installed in a separate boiler room. In this category, cast iron boilers are often found that are used to heat homes of more than 200 square meters. meters and more. |

Note! Installation and maintenance of heating boilers running on trunk or bottled gas should be carried out only by specially trained people who have the appropriate permits. Without compliance with this rule, the launch of the climate network into operation is strictly prohibited.

It should be noted that the electronics of modern gas boilers are very sensitive to the quality of the electrical network. To keep the device working, it is recommended to connect it to a power outlet using a voltage regulator. Even better - buy an uninterruptible power supply or diesel generator. So you can ensure the operation of the system in case of accidents on power lines.

Solid fuel: availability and power

Let us continue the comparison of heating boilers that can be used to equip autonomous heating systems.

The next after gas in terms of popularity and prevalence are heating boilers - Cooper, Smoke, Bourgeois and others working on solid fuel. The scheme of their functioning is even simpler. Fuel creeps into the combustion chamber, which, burning, gives up heat to the fluid circulating through the pipes.

The disadvantage of such devices is that as soon as the fire burns down, the coolant begins to cool rapidly, and the temperature in the rooms rapidly decreases.

As for the benefits, then you can include the possibility of choosing a fuel. The omnivorous heating boilers Karakan, Taiga and others have proven themselves to be excellent.

In the combustion chamber of such units, you can lay:

- firewood and waste wood production;

- brown coal, anthracite and coke;

- fuel briquettes and pellets;

- peat.

Note! There are also universal units. Using the included spare parts, they can be converted in minutes to use liquid fuel, gas or electricity, and sometimes all at once.

On the modern market there are two main types of solid fuel boilers, each of which we consider more closely.

Classic boilers

The features of these heaters are as follows:

- They have a large firebox that allows you to put a lot of fuel to ensure a long cycle of work without human intervention.

- Due to the simple design, they are distinguished by a low price. The cost of classic solid fuel boilers is one of the lowest on the market.

- In the furnace you can burn almost any fuel, regardless of its quality.

- The efficiency of heating devices is not too high.

Long burning boilers

This category of devices includes heating units of two types:

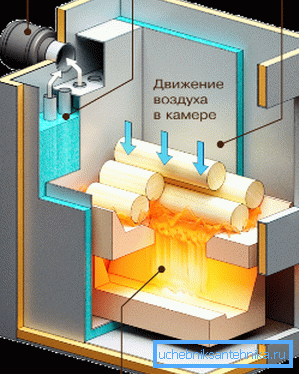

- Hydrolyzed. The basis of their work is the principle of decomposition of organic substances into components under the action of temperature. As a result, a special pyrolysis gas is formed, which is once again burned, forming more thermal energy.

These devices are characterized by a long period of burning on one tab of the fuel, increased efficiency and the ability to precisely adjust the operating parameters with the help of specially installed electronics.

- "Smoldering" type. In these boilers, the combustion of fuel occurs gradually, from top to bottom. A very large camera allows you to load a considerable amount of fuel, so the heaters can operate on one load up to a day.

Both of these devices have a special feature - the fuel loaded into them must be of very good quality (for example, wood moisture content of at least 20%), otherwise it will not be possible to achieve high efficiency.

Liquid fuel: autonomy and reliability

We will continue to consider existing boilers on the market: heating can also be organized with the help of units operating on liquid fuel, which operate autonomously and do not require constant attention from the person. These include heating boilers for fuel oil, diesel fuel and used engine oil.

The advantages and disadvantages of the considered equipment are reflected in the table:

| pros | Minuses |

| Have high efficiency. Up to 94% of the energy of combustible fuel is transferred to the coolant. | The cost of the described equipment is one of the highest in the market. |

| Causes minimal damage to the environment. Only a small amount of harmful substances is released into the air. | To install the device, a special boiler room must be equipped with a chimney, ventilation and pumping equipment for diesel fuel. |

| With the help of special equipment, it is possible to organize a fully autonomous heating system, independent of public utility networks. | Boilers must be connected through special fine filters to prevent burner failure. |

Note! The heating boiler for fuel oil or diesel fuel during the heating season uses a lot of fuel, which must be stored in a special heated tank. Otherwise, diesel fuel will thicken, which can lead to breakage of pumping equipment and clog filters.

Electricity: Convenience and Versatility

It remains to consider another type of boiler - electric. It must be said right away that these devices have excellent consumer characteristics, but one major drawback is the cost of energy carriers.

The price of electricity, compared with other fuels, is the highest on the market. In addition, not every modern power line (especially in rural areas) is able to withstand such a load. Therefore, email. boilers are used only as additional or reserve.

The following types of equipment are on the market:

- Ionic boilers. Another name is electrode. In them, thermal energy is formed under the action of the resistance of a fluid when electric current passes through it from one electrode to another. The advantages of such boilers - low cost and compactness, minus - high requirements for the coolant.

- Inductive devices. Here, the electric current does not pass through the liquid, and heat is generated due to electromagnetic induction. A prominent representative of such boilers is the Volcano produced by the Russian company Galan.

- Tenovye. Water is heated with tubular electric heaters. The boilers are compact enough, but often fail when using unprepared coolant.

Conclusion

The choice of the boiler according to the type of energy it uses is only the first stage. It is equally important to correctly select the power of heating equipment. It is the amount of heat produced by the device that determines the comfort in the house and the efficiency of using the unit.

How to do this, see the video in this article.