Heating boilers of long burning on solid fuel for

Today, natural gas lines are suitable only for a small number of localities, if we talk about the situation in the country as a whole. In many cases, the main sources of heating for summer cottages and residential buildings are long-burning heating boilers for solid fuels. They make it possible to provide heat to any buildings, regardless of their location.

Advantages of designs

Modern products for heating the coolant in the systems of suburban and residential buildings by burning wood, coal and vegetable fibers are innovative. Using affordable fuel, the price of which is relatively low, you can significantly reduce heating costs.

The main advantages of the products are presented below:

- The combustion process is successfully adjustable., which is carried out by overlapping and supplying air.

- High level of automation provided by the control panel, which provides the ability to adjust the temperature.

- Complete device autonomy allows you to operate in a variety of conditions.

- The possibility of installing their own hands is another step to saving money.

- Due to the special principle of operation in such systems, a relatively small amount of ash and soot is deposited..

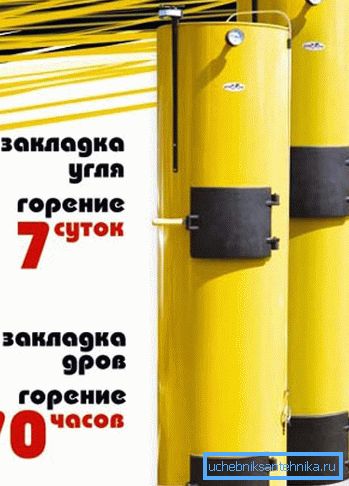

Addition! Modern heating boilers with long burning on the wood are able to function after one laying up to 70 hours. In the case of coal, this period is extended to 7 days.

Principle of operation

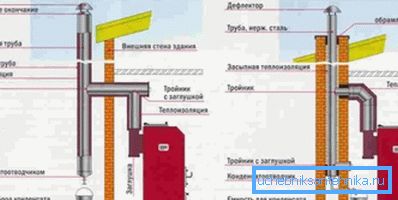

The basis of the operation of devices capable of burning fuel for a long time is a rather simple principle. The contents of the firebox burns down from the top down. Immediately before being fed into the compartment with a flame, the air flows heat up, and then get directly into the chamber with a high temperature. The lower layers are not affected.

It is further proposed to explore some of the features possessed by solid fuel boilers of long burning on coal, wood, or any other organic fuel.

- These devices do not contain a grate and an ashpit, and below there is only a deaf pan.

- The furnace has a cylindrical shape. Air is directly blown into it.

- At the entrance to the afterburning chamber there is a device that regulates the traction. It functions by determining thermal expansion.

- Due to the mobility of the air distributor during the laying of the fuel, the upper layers are burning.

Note! In the air supply zone, partial oxidation of the combustion products takes place. Together with the ashes, they fall into the upper compartment of the firebox, which is enclosed by a massive metal disk.

Manufacturing materials

The production process of boilers designed for long-term combustion of solid fuels is rather complicated. Cast iron or steel is used as the main material, because only with their help the necessary strength characteristics can be achieved.

Cast iron products

The service life of such units with proper operation is very long, which is associated with high resistance to corrosion and thermal effects. Both points are very important, because the device always has to contact with an open flame and transfer the effects of condensate. (See also the article Boilers for heating with wood: features.)

Steel appliances

Especially popular are boilers made of steel. They are produced by welding individual elements. Unlike previous analogues, these products are lightweight, and this simplifies the process of transportation and final installation.

Classification methods

There is a division into categories by type of fuel. The devices can work directly on wood, coal or pellets, which are compressed wood waste. Universal boilers can operate on different fuels.

Another option is to classify by functionality. Thus, it is possible to distinguish single-circuit and double-circuit products. In the first case, only the heating of the rooms is carried out, and in the other - the heating of water for household needs.

The number of combustion chambers is also taken into account. Designs with one firebox require reconfiguration when using different types of fuel. Analogs with two cameras allow you to avoid this process. In addition, they are more efficient anyway.

The devices are also classified according to the boot method. Household models usually suggest the presence of manual bookmark fuel. In industry, automated pellet heating boilers are actively used. Fuel consumption is easy to adjust.

Recommendations for use

- If the device is in working condition, flammable objects should be placed at a distance of at least 25 cm.

- Do not melt with diesel fuel, gasoline, kerosene, glossy paper and other materials containing harmful substances.

- It is necessary to regularly inspect the technical condition of the equipment in order to timely troubleshoot.

- It is necessary to load only the maximum dried fuel into the combustion chamber, otherwise the efficiency will be significantly reduced.

As a conclusion

The instruction was given in order to give a complete picture of what are heating boilers of long-term burning on wood, coal and other types of solid fuels. In many parts of our country, they will be relevant, as gas mains and electrical networks are not well developed. For detailed acquaintance with the products attached a special video.