Heating flap will increase the efficiency of the cooking

Metal cooking and heating-cooking stoves have one undoubted advantage - compactness. Such a unit will not take up much space in your home or country house. To improve the efficiency of steel and cast iron stoves, a brick heating shield is used.

Disadvantages of metal cooking stoves and how to fix them

- The compact dimensions of metal stoves have a drawback - too small an air heat exchange surface.

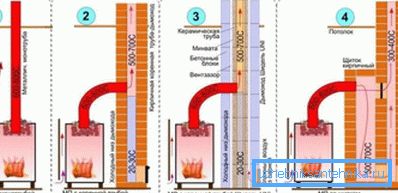

- In addition, the gaseous products of combustion have a very high temperature - from + 300 ° degrees and more. Therefore, we have to think about fire safety and insulate the chimney.

- As is known, the efficiency of stoves is proportional to the inverse temperature of the waste of combustion. For cooking, cooking units use far from all the generated thermal energy.

- In addition, such furnaces usually have short chimney channels. Therefore, they are absorbed a little heat.

Note! For all these reasons, the instruction notes that the maximum heat loss of the units falls on the chimney, through which the combustion products are released into the atmosphere. That is, in fact, a large percentage of the heat from the used fuel cooking stoves spend on "heating the street."

- Such heat losses are irrational from any point of view. There is a need to minimize them. One of the most common ways to reduce the energy loss of a furnace is to equip the unit with your own hands with a heating shield.

What is a device

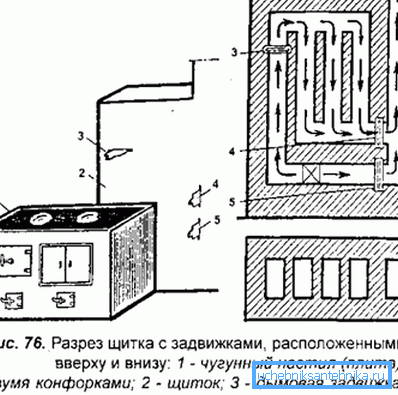

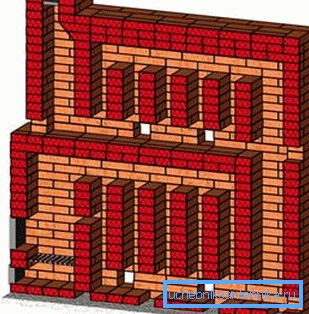

- The flap is a small brick wall attached to the furnace, inside of which there is a developed system of chimneys..

- Such devices are almost never made with a firebox.. The shield is heated due to the gases removed from the stove. Structurally, the wall is not able to throw a lot of heat into the environment.

- There are more complex and convenient designs, the price of which is higher. They are equipped with their small furnaces. They can be made independent of the cooking plate and attached, for example, to stoves with a fireplace.

- The brick has good thermal conductivity, and most importantly - high heat capacity. Warming up when kindling the stove or cooking, it gives off heat to the room for several hours. So you can get an analogue of a brick stove. Only more simple constructively and for less money.

Note! The heating and cooking furnace with a guard is capable to have a thermal power of 7/14 kW. When the fuel burns, the wall for a long time gives to the environment about 1 kW of heat. In order to warm up the room independently, this is not enough, but so that it does not dry out quickly, this amount of energy is enough.

Constructions of devices

The designs of the heating plates are divided into two broad categories: they can be thick or thin-walled.

About wall thickness

- Thick-walled plates are laid in half-brick. They must be preheated well. When a cooking stove with a heating flap is used constantly, such a device is advisable. Among other things - thick-walled structures are preferable from the point of view of fire safety.

- Heating thin-walled flap is placed in a quarter of a brick. To meet fire protection requirements, such structures are often covered with metal covers.

- The surface of the walls can be plastered, tiled with tiles or, having finished the joints, left without finishing. It is necessary to revet the furnace fireplace with a heating guard during its laying.

- The devices can operate in two modes of operation - winter and summer. In the first of these, the design heats up completely, in the second partly.

Note! When the heating shield is laid, increased fire protection requirements are applied to them. For example, the device should be built necessarily on a separate foundation. It must be waterproofed.

What clutch to prefer

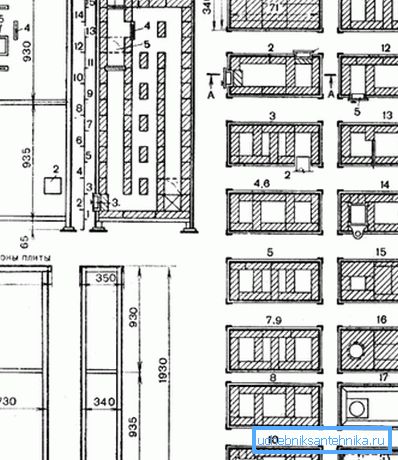

Laying out the heating plates with their own hands, taking into account several recommendations.

- More rational construction in half-brick. Thin-walled structures are heated faster, however, and cool quickly.

- Laying in? bricks, in addition, requires to comply with increased fire safety measures. So, it is desirable to take such shields into a steel casing.

- The temperature of exhaust combustion products should not be less than + 100 °. Otherwise, the traction in the furnace may drop significantly, and condensate will begin to settle on its elements.

- As in all furnace chimneys, in valves should use valves for adjustment. Otherwise, in cold weather, the temperature in the rooms will drop very quickly.

- The order of the heating shield is made from ordinary red bricks. They must be corpulent, the gap in the material needed for insulation, but it is in this case, to anything.

- For the masonry bonding it is necessary to use an oven clay mortar. Cement-sand mixture is not resistant to high temperature.

Work schemes

According to the principle of operation, two types of devices are distinguished.

Channel shields

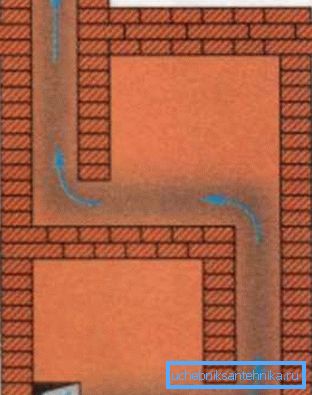

- Inside this device there is a kind of labyrinth of chimneys that have the same section.

- When such heating plates are placed, they can have both horizontal and vertical partitions.

- Thermal energy to the walls of the combustion products give in the process of uniform movement along the entire length of the channels.

- In the duct-type devices, bridges often bypass the chimney. They are fenced off by partitions. It is necessary that in the summer period the cooking stove does not heat the room.

In furnaces-fireplaces jumpers are not needed, because they are equipped with shields for greater heat transfer. The device for a powerful metal unit, for example, for Bavaria (thermal power of 14 kW) without such a jumper should not be done. (See also the article Biofuels for fireplaces: features.)

Bell devices

The heating shield of kolpak type consists of one or several cavities, which are connected by chimneys. The exit and entrance of the channel in all caps is made much below the top of its plane.

Why is this necessary? Heated air and furnace gases always flow upwards. Penetrating into the cap, the gases before they cool will be located there. When they give up their heat, they will be replaced by a new portion of heated combustion products, and they will flow down the chimney to the street.

Note! It should be borne in mind that the two-flap shield will take more heat from the waste products than the single-flap counterpart. Their cost is the same, because material costs are equivalent.

Features of the implementation of the circuit board

- In addition to rectangular devices, when there is not enough space in the room, a corner shield is often equipped. In addition to the fact that this design saves a useful volume, due to the larger heat exchange area, it gives off more energy.

- If you equip the flap with a separate firebox, it is converted from an additional element of the stove into a full-fledged heating equipment.

- Own fuel chamber is needed in order to not needlessly to melt the cooking stove. (See also the article Heating a private house with firewood: features.)

Conclusion

Making a heating shield with your own hands, you will significantly increase the productivity of the main furnace, thanks to the improved heat exchange in the room.

Check out the video in our article, it contains a lot of additional information.