Heating furnace buleryan - devices and features

Furnaces Buleryan are one of the most effective types of solid-fuel heat generators - the efficiency of these units reaches 80-85 percent. At the same time, fuel consumption is very slow and economical.

In this article we will examine in detail the devices of these furnaces, we will get acquainted with their types and features.

First of all, it should be noted that the Buleryan furnaces were developed 16 years ago. Since that time, they are always popular. Initially, these devices were produced under the brand name Bullerian, but in the 2005th year, as a result of the rebranding, they received their present name - “Breneran”.

Therefore, at present these furnaces are known under the names of Buleryan and Breneran.

Oven features

Principle of operation

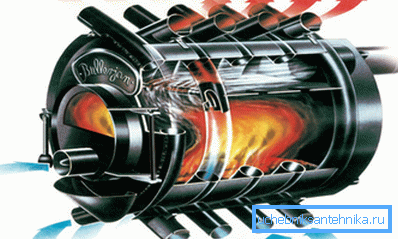

Heating furnaces Buleryan represent an all-welded construction, girdled by a set of pipes. The cold air, concentrated near the floor, is drawn in by the lower pipes, and as it passes through the pipes it heats up. As a result, air flows heated up to 100-150 degrees go out through the upper pipes.

In addition, the body of the structure itself is heated, which also transfers heat to the surrounding space.

Thus, the furnace provides heating by all existing methods today:

- Heat exchange;

- Heat transfer;

- By convection.

This property explains the high efficiency of the structure.

Moreover, the device can work in two modes:

- Fast heating - the device as quickly as possible (within 15 - 20 minutes) warms up the room.

- Gasification - maintains a constant set temperature due to the slow combustion of the fuel.

At the first stage, fuel is put into the furnace, which burns through and thereby heats the chamber. After that, fuel is loaded into the chamber again, after which all doors and flaps are closed.

From this moment begins based on the operating mode of the furnace - corruption, which can last up to 12 hours. During this process, wood gas is formed, which, when burned, emits significantly more heat energy than wood. Due to this, the temperature of the air leaving the nozzles can reach 150 degrees.

As fuel in these furnaces can be used:

- Firewood;

- Briquettes;

- Pellets,

- Cardboard;

- Peat, etc.

Note! On the other fuel units will not work, because only wood provides the necessary chemical and physical processes. Therefore, before stopping the choice on this variant of heating, you should make sure that the wood in your area is available and at a reasonable price.

Usually, furnaces require only 2-3 bookings of fuel per day. At the same time, it is possible to regulate the amount of heat produced using the power regulator located on the firebox door. In addition, the same function is performed by the regulator-gasifier located on the smoke pipe.

The smallest model of the furnace can let through up to 4.5 meters of cubic air within one minute, which allows heating a relatively large area in a short time.

Design

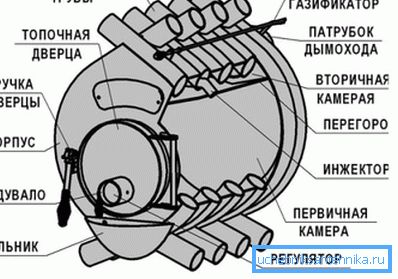

The design of the ovens is quite simple, but at the same time original. It consists of the following nodes:

| Housing | Represents the cylinder reminding a metal barrel. The case of the unit consists of two parts:

|

| Air pipes | Bend around the combustion chamber, passing through it. As mentioned above, pipes are used for convection of air. |

| Outlet | Designed to connect the chimney through which the output of combustion products outside the room. |

Note! Instructions for the use of furnaces Breneran implies a high-quality ventilation of the room. This is due to the fact that even a minor defect in the chimney system can lead to the accumulation of carbon monoxide.

Merits

Among the advantages of the heat generators in question, first of all, safety can be distinguished, since the construction does not heat up and, accordingly, does not burn oxygen in the room.

In addition, there are many other important advantages:

- Efficiency - the device is able to quickly warm up even very large premises.

- Full autonomy - the furnace does not depend on electricity and gas.

- Heating is carried out uniformly.

- The unit is easy to maintain with your own hands, since the ash is almost completely absent, and at the same time the temperature is maintained consistently for 11-12 hours.

- The ability to control the process of burning.

- On one tab of fuel the device can work 8-12 hours.

- Large selection of models that are designed for space heating volume from 100 to 1100 cubic meters.

- The efficiency of the heat generator is 85 percent, which is largely achieved due to the complete combustion of gases.

disadvantages

The disadvantages of this design are also present, as with any other heating equipment.

The following are the main ones:

- Ability to work only on solid wood fuel.

- The need for warming the chimney.

- The need to bring the chimney to a height of at least three meters from the top edge of the furnace.

- The inevitable burning of dust, as some parts of the furnace still heat up to temperatures above 120 degrees Celsius.

Note! Stoves Buleryan can not be installed at a distance closer than one meter from the wall.

Furnaces Buleryan with a water circuit

Recently, a special kind of the described apparatus has appeared - heating boilers Buleryan. Of course, convection ovens are much more efficient than conventional, but they are still inferior to water heating systems.

As a result, the designers came up with the idea of supplying such heating stoves with a water circuit. This solution turned out to be very successful, as a result of which the devices began to be in great demand among consumers.

Currently, water heating can be purchased under the brands "Breneran-Aquathen" and "Aqua-Buleryan". In addition, there are some other modifications.

As it is not difficult to guess, the term “aqua” itself means that the unit is supplied with a water circuit. In these devices, the heat exchanger passes through 70% of the total perimeter of the combustion chamber. As a result, water heats up quickly, and there are no sharp temperature drops and pressure fluctuations.

The efficiency of such boilers is 70/75 percent, which is comparable with the indicators of gas heating devices. It should also be noted that they have one important advantage over conventional Brenern stoves - the outer surface does not heat up so much. Thanks to this feature, the units can be installed in small rooms.

It is possible to use heating Buleryan in private houses, at dachas, in production rooms and public places.

Note! It is possible to use the considered boilers only in heating systems with natural circulation of the coolant.

Here, perhaps, are all the main features of Bullerian stoves.

Conclusion

Furnaces Buleryan are an effective way to heat the rooms and are an excellent choice in cases where there is no possibility to use gas equipment. However, it is necessary to take into account some of the drawbacks of this equipment in order to minimize them (see also the article Long-heating stoves: design features and purpose).

From the video in this article, you can get more information about the furnace Buleryan.