Heating furnaces with a water circuit: the main types and

In this article, we will look at what a furnace for heating with a water circuit is, what their working principle is and what their design features are. In addition, we will talk about which modifications of these devices are on the market and which of them can be chosen for use in a country house.

The question of heating country houses, cottages and cottages, each person decides because of their preferences, capabilities, and in accordance with the characteristics of the construction site. Unfortunately, it is not always possible to install a gas heating boiler for full-fledged comfortable operation, since the gas distribution pipeline may be located at a significant distance from the house.

In this case, the owners of the construction site are trying to solve the problem by installing a traditional brick stove with or without a hob. Usually, the hob and firebox go to the kitchen, while the back side of the building is directed to the living room.

If desired, such a structure can be equipped with a mass of useful and functional devices, such as, for example, a stove bench, an oven, a place for drying firewood, etc.

But, unfortunately, the furnaces built on the old-fashioned technologies are characterized by one major drawback - they are deprived of a water circuit in which the coolant could heat up. Thus, pipelines and radiators cannot be connected to these heating devices and, as a result, it is impossible to ensure uniform temperature throughout the house.

But, as it turns out, if it is not possible to connect a modern gas boiler, it is not necessary to resort to old-fashioned technologies, because a wide range of heating equipment with a water circuit, designed for other types of fuel, is on the market. Moreover, the stove with water heating, if desired, can be made by hand using materials such as brick or sheet steel.

The principle of operation and features of operation

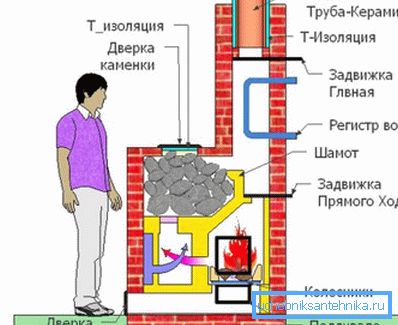

Both classic and modern stove for heating with a water circuit provides an even distribution of heat throughout the heated rooms due to the circulation of the coolant.

The principle of operation is as follows:

- The fuel from the storage tank enters a special chamber where ignition and combustion take place.

- Above the chamber with an open flame is a heat exchanger that heats and warms the water. The heat exchanger, most often, works as a register (radiator in the form of a coil) through which running water passes.

Depending on the number of circuits, the number of heat exchangers in the furnace is determined.

- The heated water leaving the heat exchanger enters the system or into the pipeline.

- For the circulation of the coolant in the system can answer the expansion tank or circulation pump for heating.

Important: Modifications equipped with an expansion tank are categorized as non-volatile devices, while devices equipped with a circulation pump imply the need for constant power supply.

Ability to automate

Depending on the design features of the equipment and the type of fuel used, some factory-made furnaces can be equipped with automation systems.

Instructions for the use of such systems provides the ability to automatically supply energy to the combustion chamber. In addition, at the specified time, the burner is ignited and forced air is supplied to create optimal thrust.

Important: Equipment running on natural gas and electricity can operate completely independently of the human presence during the whole season. Automation of solid fuel and liquid fuel units provides independent operation for 1-7 days, after which you will need to re-adjust the work schedule.

Advantages and disadvantages

Furnace heating with a water circuit is characterized by a number of advantages and disadvantages that must be taken into account when choosing the right option.

Among the advantages we note the following:

- Performance, sufficient for heating of country houses with an area of up to 150-200m ?;

- Possibility to choose a heating stove, working on the type of fuel that is available and the price of which makes heating the room cost-effective;

- Simplicity and reliability of a design and as a result, the predictability of exploitation;

- Ability to choose between volatile and independent modifications taking into account the features of the construction site and the state of engineering communications in combination with the stability of the power supply, etc .;

- Affordable price in comparison with the cost of construction of traditional brick kilns.

Among the shortcomings we note such moments as:

- Automation of heating equipment costs a lot of money, and therefore for an affordable price you can count on primitive devices with manual fuel supply and with manual temperature control.

- Most of this equipment implies the need to build a special boiler room.

- Again, for solid and liquid fuels you will need to equip a special storage or storage room.

- Furnaces with a water circuit demonstrate a lower level of efficiency than a similar parameter typical of modern gas boilers.

Criteria for classification and actual varieties

Heating stoves that can work with water heating are classified according to criteria such as:

- type of production materials;

- type of fuel used;

- method of circulation of the coolant;

- gas discharge method;

- power parameters;

- functionality, namely the presence of such options as water heating for water supply, equipment with a hob, etc .;

- degree of automation and, as a consequence, type of energy dependence.

In accordance with the type of production materials, two types should be noted:

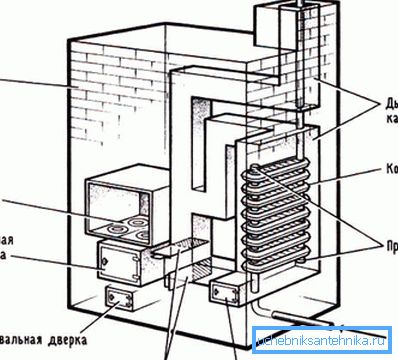

Brick kilns are structures designed exclusively for burning solid fuels (firewood, pellets and briquettes, pressed from waste, coal).

A register is used as a heat exchanger in such structures. A register is a type of radiator made of a pipe of a certain diameter and equipped with metal fins that serve for more efficient heat extraction.

A significant drawback of such a design is the impossibility of fully automating all processes, including the supply of fuel, temperature control, frequency of start-up, ignition, etc. Again, the contour in the brick structures, most often, one.

Important: Brick heating cooking stoves with a water circuit can not be purchased in finished form in a specialized store. This equipment will have to be built from scratch with your own hands, which will require considerable effort, time and building materials.

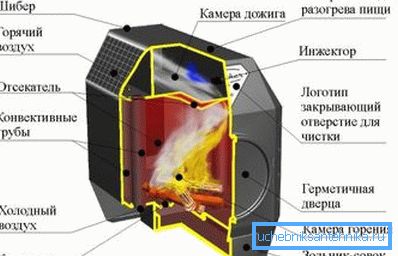

Metal furnaces are more technological designs from steel or cast iron. Among these aggregates should be noted solid and liquid fuel modifications.

The design of solid fuel units is not much different from brick counterparts with the difference that the dimensions of the metal furnace is an order of magnitude more compact and the mass is several times smaller. As a result, it is possible to install a metal product on an ordinary cement or tiled floor without the need to lay the foundation.

Fuel oil steel or cast iron stoves are even more compact compared to solid fuel options. Diesel fuel is used as an energy source in such devices.

In connection with the rise in price of diesel fuel, furnaces designed for incineration mining are becoming increasingly popular everywhere. In order not to spend money on the purchase of expensive devices of foreign production, some craftsmen make special burners with their own hands.

As a result, the operation of furnaces equipped with such burners, at the expense of cheap waste oil, costs a minimum amount of money.

Conclusion

A simple heating furnace with a water circuit with your own hands can be built according to the schemes given in this article. However, you can save time and effort, and purchase a ready-made metal device.

The use and maintenance of a water circuit furnace, regardless of the modification, is not particularly complex. However, if explanations are needed, you can watch the video in this article.