Heating installation: tips on choosing autonomous system

The topic of this article is the installation of heating systems in private homes. We will address the problem of choosing the source of heat and heating devices. In addition, we have to get acquainted with a rather unusual heating scheme, applicable in warm regions.

Heat source

So, the walls of the house were erected and covered with a roof; windows and doors installed. It's time to think about heating.

Before proceeding with the installation, it will be logical to calculate two parameters:

- The need of the house for thermal power;

- Operating costs. They depend on both the power of the heating equipment and the source of heat.

In addition: the need to maintain equipment will be an important factor. For obvious reasons, it is worth giving priority to a device that can operate in the most autonomous mode.

Efficiency

We give a list of popular solutions with an indication of the cost per kilowatt-hour of heat.

| Heat source | Price kilowatt-hour, rubles |

| Electricity (direct heating) | 3.8 |

| Diesel fuel | 3.2 |

| Pellets (pressed sawdust) | 1.4 |

| Coal | 1,3 |

| Firewood | 1.1 |

| Gas | 0.7 |

The convenience of use

But the rating in terms of autonomy and ease of maintenance:

- Electricity. The boiler and other electric heaters do not require maintenance or disposal of combustion products.

- Gas. Autonomy is almost as good as electric boiler.

- Solarium. Diesel heating systems can operate for a long time without maintenance; However, the disadvantages of the solution are high noise levels and the need to store a large amount of fuel.

- Pellets. Every few days it is necessary to load the bunker and clean the ash pan.

- Coal, firewood. The kindling is required every few hours.

Gas is clearly leading in terms of efficiency and ease of use. And what should the inhabitants of settlements in which there are no gas mains do?

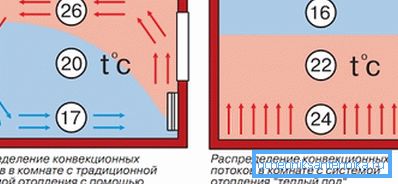

If convenience is the main selection criterion, our choice is electricity. Operating costs can be significantly reduced by using underfloor heating systems and infrared heaters.

The first more rationally distribute heat in the volume of the room; the latter make it possible to significantly reduce the threshold for a comfortable temperature.

If profitability comes first, here are a few ways to increase the periods between the kindling of a solid fuel boiler.

- The so-called pyrolysis boilers break the process of burning fuel into two stages. At first it smolders with limited access of air; then combustible products of incomplete combustion are burned in a separate chamber. This allows you to increase the period between kindling up to 10 hours and get rid of the drop in efficiency at low power.

- The upper combustion boilers transfer the process of fuel smoldering from the lower to the upper loading surface. Ash is carried away by the upward flow of combustion products. The best samples of products of this type are capable of autonomous work within 25-30 hours.

- Finally, a heat accumulator placed in the circuit (a massive heat-insulated tank with water) allows for a long time to heat the house with heat accumulated in it without kindling the boiler.

Heat from the air

In regions where winter temperatures do not fall below -10 - -15C, in the absence of gas, air conditioners are often used to heat homes. Inverter air conditioner is capable of pumping 4–5 kilowatt-hours of heat into a house for every kilowatt-hour of electricity it spends.

As it is easy to calculate, in this case, operating costs equal to the cost of wood or coal; at the same time, the autonomy and flexibility of adjusting the system will be at least at the level of a modern electric boiler.

Installation of heaters of this type will cost 4-6 thousand per room, which is quite comparable with the cost of installing water heating. A slightly higher cost of equipment (from 22 - 25 thousand for one inverter with a capacity of 9000 BTU) will quickly pay for itself by saving on fuel.

Heating appliances

Let's return, however, to water heating. What heating devices are better to use in an autonomous system?

Let's remember the conditions in which they will work.

- Normal temperatures in the autonomous circuit are 70–80 ° C at the supply and 50–60 at the return pipeline.

- Pressure - from 1 to 2 atmospheres (kgf / cm2).

- Water hammer in the presence of common sense from the owner of the house is completely excluded.

If so - you can with a light heart advise opt for aluminum sectional radiators.

They do not have a large margin of safety (as a rule, the working pressure is 9–16 kgf / cm2); but other properties are beyond praise:

- Heat transfer reaches 200 and higher watts per section.

Nuance: manufacturers indicate the heat flux for the delta of temperatures between the radiator and the air in the room, equal to 70 degrees. At half the delta, the heat output will be halved.

- Appearance of batteries will allow them to fit into any design of the room.

- Section cost rarely exceeds 300 - 350 rubles.

Pipes

Which pipes should you prefer when installing heating with your own hands?

- Reinforced polypropylene will be the optimal choice for sequential (tee) wiring.

- If the heating system is installed with collector wiring, cross-linked polyethylene or metal-plastic pipes with press fittings are often used.

For the selection of the diameter in the general case should be carried out hydraulic calculation; however, with a small area of the building (no more than 150 m2 per floor), you can focus on the following values:

| System element | Inner diameter |

| Bottling | 25 mm |

| Radiator outlet | 15 - 20 mm |

| Layout from collector | 15-20 mm |

A caveat: in shops, pipes are often labeled not by internal, but by external diameter. As a rule, it is one more step: for example, with an inner diameter of 20 mm, the polypropylene pipe has an outer diameter of 26 mm.

Additional elements

The installation of closed-type heating systems is accompanied by the installation of some additional elements.

We give them a short list.

- An automatic air vent removes air plugs and steam from the circuit when the coolant boils.

- The expansion tank compensates for a change in the volume of the coolant when its temperature fluctuates. The simplest instruction for the selection of the tank looks like this: its volume is taken equal to 1/10 of the amount of coolant in the circuit.

- The safety valve relieves excess pressure when the tank is full.

- A pressure gauge is used to visually monitor pressure.

- A circulation pump circulates in the circuit.

Curiously: these elements are often supplied as part of modern boilers.

- Separate radiators are supplied with throttles and shut-off valves. More convenient (but more expensive) thermostatic heads can be used instead of chokes.

- Additional air vents are installed at the upper points of the circuit, and waste valves are installed at the lower points.

Conclusion

We hope that our brief excursion into the device of modern autonomous heating systems will help the reader in choosing equipment for their own needs. As always, additional information can be found in the attached video. Successes!