Heating pallets - in harmony with nature

Pallets (pellets, pilots) or euro-fuel can be characterized by such words as clean, compact, comfortable. Steady heat and long burning made these babies more popular. They can also become your “favorites” in the matter of heating a country house or a dacha, especially if civilization in the form of a gas main has not reached your places.

Small pallet yes fuel

Renewable energy sources - land, water, sun, are becoming increasingly popular as a fuel material for country houses.

Special attention should be paid to heating with pillets - cylindrical pressed granules, which are produced from biological raw materials:

- huskies;

- wood;

- household waste;

- sea grass;

- peat;

- straw.

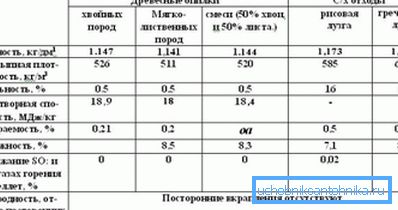

The extraordinary hardness of the pellets gives lignin - a substance originally contained in the material. If oak wood has a density of 640, birch - 570, aspen - 370 kg / m3, then in the finished granules, the indicator increases to 1100-1400. Due to this density, the granules are so heavy that they sink in water.

This physical quantity offers undeniable advantages when it comes to:

- fuel quality - “fresh” firewood contains from 40 to 50% moisture, which cannot be said about pellets;

- heat transfer - up to 19 MJ / kg. For clarity, 1 kg of granules will be enough to heat about 45 liters of water from 0 ° C to a boil;

- profitability - 1 ton of pellets is equivalent to 1.5 tons of firewood or 500 liters of diesel fuel;

- wastelessness - low ash content - up to 1%, contributes to the formation of ash minimum (15-20 times lower than after burning coal), but it can also be used as a valuable mineral fertilizer;

- health safety - pellets emit a minimum of carbon monoxide.

Two sides of the coin

Every thing in the world contains positive and negative qualities and pellets are no exception.

The disadvantages include:

- high price of boilers especially compared to gas or electric. The boiler with a power of 15–20 kW costs from 4000 at. e.

Note! In solid fuel boilers, it is possible to replace the burner with a pallet burner, which will help save up to 1000 u. e.

- the possibility of servicing equipment that can become a headache if the center is too far away;

- the hypothetical possibility of breathing in the harmful substances emitted by the granules, if they were produced from low-quality raw materials. However, there is a risk to fall on the unscrupulous manufacturer, even when buying toilet paper.

Note! In solid fuel boilers, it is possible to replace the burner with a pallet burner, which will help save up to 1000 u. e.

The bright sides of the pellet fuel more and it pleases:

- environmental Safety;

- the use of biofuels has no restrictions - from boilers and power plants to the usual rural house;

- the ergonomic dimensions of the Euro fuel allow you to conveniently store large quantities in small areas;

- lack of possible spontaneous combustion;

- a wide range of prices allowing the buyer to make his choice - on average from 3200 to 7000 rubles per ton;

- relative autonomy of the heating system;

- high calorific value.

Note! The absorbent properties of the granules are useful for alternative use, for example, as a cat litter or for collecting spreading engine oil.

Himself an expert

Having the minimum necessary knowledge about the properties of Euro fuel and the main requirements that are imposed on it, you can avoid annoying mistakes.

Instructions for determining the quality of fuel is simple:

- the surface of the cylinders should be perfectly smooth, polished and shiny. Gray patina indicates stale goods;

- standard diameter from 6 to 8 mm;

- faint sweet smell, which depends on the raw materials used;

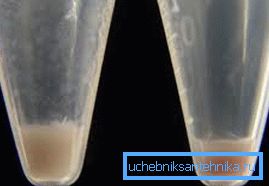

- after a while, the granule is soaked in water, but if it does not lose its shape, it means that an extraneous binder was used in the production process;

- arranging a storm in a glass of water, well visible impurities - sand, dust from grinders;

- We look at information about the manufacturer - large production, as a rule, uses the raw material of one supplier and values its reputation.

Pallet Recipe

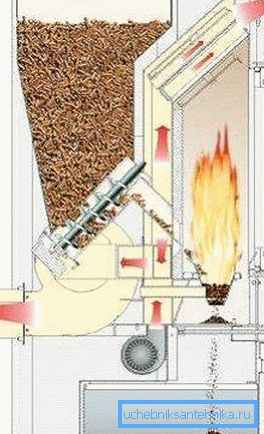

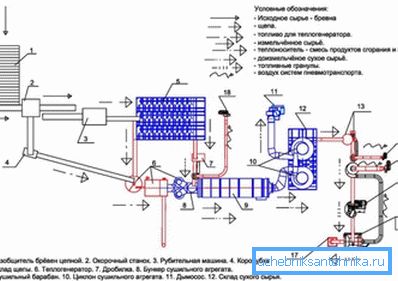

The manufacture of pallets for heating takes place in accordance with GOST R 54220-2010 and includes the steps of grinding raw materials, drying, water treatment, pressing and drying:

- Primary crushing of raw materials into fragments of size 25x25x2 mm, which will facilitate their drying.

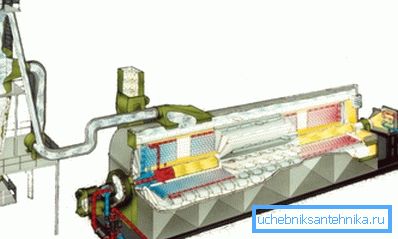

- In a dryer, drum or belt type, using electricity, the moisture of the crushed material is brought to 8–12%.

- After secondary crushing, pieces of raw materials are crushed to the size of no more than 1.5 mm. Bulk weight 150 kg / m3 ± 5% will indicate high product quality. Sawdust, shavings and chips are processed on hammer mills.

- Too dry / wet fine fraction poorly pressed. Mixing biosix in screw mixers, water is dosed to it for soft woods, or hot steam for hard ones.

- Pressing with the help of flat / cylindrical dies gives the output the familiar form of pellets - with a diameter of 6 mm for the consumer and 10 - for the industry.

- Cooling, besides the direct destination, also dries the granules that come out of the press heated to 70–80 ° C.

- Finished products are sifted and packed in 20-kilogram bags or stored in bins.

The complexity of the technological process makes the production of fuel in the home is a difficult matter - in the manufacture of equipment with their own hands the main problem becomes the manufacture of the matrix.

And energy-intensive, which is important - for drying, for example, 1 ton of sawdust is spent 1 MW of energy / 1 ton of moisture. With available funds, it will be cheaper to buy a pellet production mini-plant in order to receive a guaranteed profit.

Summarizing

Heating with pallets is not a cheap pleasure, especially at the stage of installation of equipment or re-equipment of an existing boiler. But everyone chooses his own way, and sometimes, what seems unprofitable and expensive now will become convenient and feasible in the future.

Using biofuels, you, if it is comforted, will make a significant contribution to environmental protection. And the vagaries of the weather - a warm winter, early spring, can lead to significant fuel savings.

If you still decide to make pallets yourself, the video will help solve the main problem - to make a matrix.