Heating pumps for home: purpose, device, selection criteria,

The heating pump for the house is a mandatory unit for systems with forced circulation of the coolant. Most modern schemes are built precisely on the compulsory principle, so the question of choosing a circulation device is very important. We will talk about the basic properties and criteria for choosing a pump for heating.

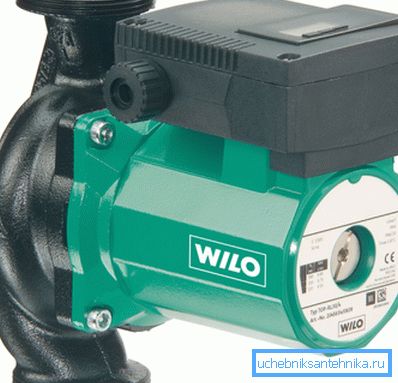

Heating circulation pump

Purpose

There are two types of organization of the movement of the coolant in heating systems:

- natural;

- and forced circulation.

Natural circulation is possible in small simple wiring diagrams, however, extensive and branched pipelines require the forced movement of fluid.

Previously, heating of a private house without a pump was used, since the units were in short supply and were quite expensive. In addition, not all settlements were electrified, and the engine of the pump is powered by electrical energy.

However, now even small systems try to do with forced circulation, as this increases the efficiency of heat transfer, increases the efficiency of heating, and the gas consumption for heating the coolant, respectively, decreases. Fuel economy in schemes with forced circulation can be up to 30% compared with the natural movement of water due to convective movement of layers of different temperatures.

Note! The circulation pump is necessary for the organization of the forced movement of the coolant due to the work of the pump with an electric motor.

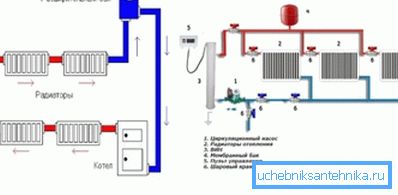

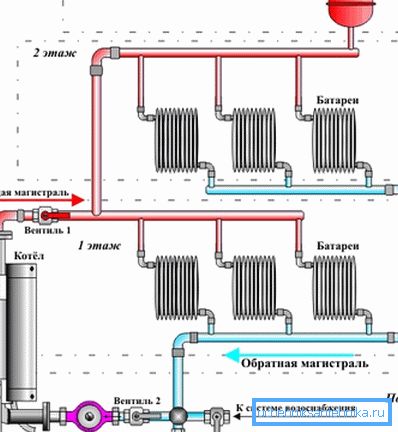

In multi-circuit circuits with collector-beam distribution, buildings with several floors and large areas of heating normal natural circulation in the heating system is impossible due to the large hydraulic resistance arising in the pipeline. To overcome this resistance, a circulation pump is needed.

Device and principle of operation

Let's understand how the pump is designed for heating a house. For clarity, we use the scheme of the main parts of the device:

So, the following units are part of the unit:

- The body of the pump, made of cast iron or stainless steel. Here is the capture of water flow rotating impeller and pumping it in a given direction;

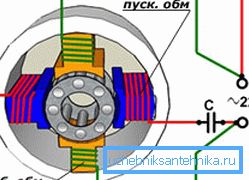

- Motor housing with stator windings. A rotating magnetic field is induced in the windings, which causes the rotor to move;

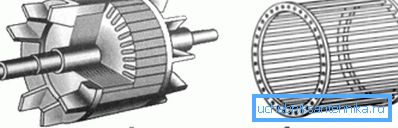

- The squirrel-cage rotor of the motor, in which the stator field induces a current interacting with the rotating armature field (asynchronous principle of operation);

- Motor shaft with ceramic bearings that transmits the torque to the impeller;

- The impeller, which rotates on the shaft and captures the fluid, carrying it out;

- Between the impeller and the rotor is a protective sleeve, which does not allow water to penetrate into the motor;

- Terminal box with control unit, speed switch or frequency converter;

- Air screw to remove excess air.

The principle of operation of such a machine is as follows: an alternating current is supplied to the stator winding and creates in it a pulsating (rotating) magnetic field with a rotational speed of 3,600 rpm with one pair of windings. The field lines of force intersect the stationary rotor and induce a current in its winding that creates the rotor field.

The rotating field of the stator captures (attracts) the rotor and causes it to rotate with it. The shaft is rigidly connected to the rotor, and therefore also rotates, transferring the force to the impeller located on it, which pumps the fluid in the pump body and creates circulation in the system.

Note! For normal operation of the unit, the pump must be filled with water, otherwise the fluid will not be gripped and the impeller will rotate at idle.

The control unit allows you to adjust the speed of rotation of the shaft by switching terminals (adding or reducing the number of pairs of armature windings) or by converting the frequency of the alternating current.

Criterias of choice

To select the appropriate device, you need to know the following parameters:

- Pressure that the pump must provide. It is equal to the total hydraulic resistance of the pipeline, measured in meters of water column;

- Unit performance. Equal to the coolant flow rate in the system, which is calculated by calculations;

- Connecting dimensions. Indicated on the motor housing, more often there are two types - 25 and 32 mm or 1 and 1.25 inches, respectively;

- Mounting or overall dimensions of the product. They should be taken into account in order for your unit to fit in the pipeline.

Note! If you look at the case labeling, you will see a numerical ratio there, for example, 32/70. The first number indicates the connecting dimension in millimeters, and the second - the pressure in decimeters, that is, 70 is 7 meters of water column.

The pressure in the system can be calculated quite simply by the formula

H = F * s, where:

- H - head in meters of water column;

- F - number of floors with a basement inclusive;

- c - averaged coefficient equal to the value of hydraulic losses on one floor of a building. According to SNiP, it is 0.7 - 1.1 m for two-pipe systems and 1.16 - 1.85 m for collector-beam systems.

For the pipeline of a private house should take the maximum value of the coefficient.

Performance is calculated according to a simplified scheme or on the basis of the flow-pressure characteristics. Simplified formula for calculating:

Q = W / 1.163 * 20 = 0.043 * W, where:

- Q - performance;

- W is the amount of heat energy required for heating the room.

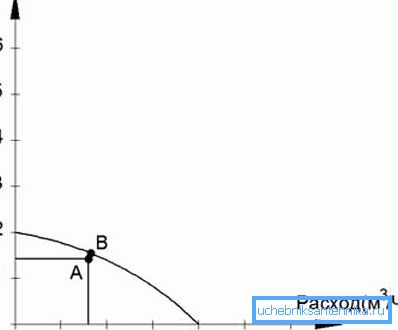

Knowing the pressure and performance, you can determine the operating point of the pump, putting the value of pressure on the vertical axis of the graph, and the flow rate - on the horizontal. Then, according to the catalog, you can pick up a device whose operating point is as close as possible to the point we have defined:

Assembly work

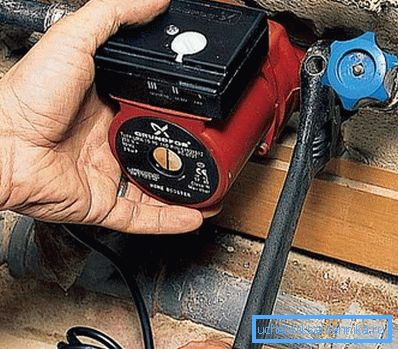

Installation instructions do-it-yourself pump is quite simple. It is installed on the return pipe not far from the boiler, since in this section of the circuit the lowest temperature of the coolant.

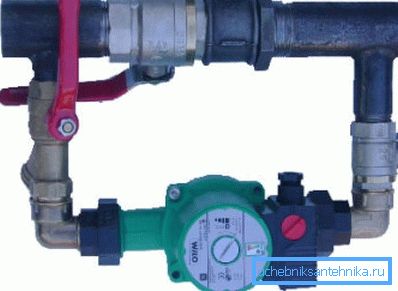

Before entering the product, a coarse water filter is cut in, and before the filter and after the pump leaves, ball valves are installed so that the device can be removed for replacement or repair without draining the water.

Often, the unit is installed through the bypass, and the bypass section of the pipe is blocked by a crane. If the pump breaks down, you can open the bypass valve for the natural circulation of fluid.

Note! After installing the circulating machine, test pressure testing of the heating system at home should be carried out using a special press.

Conclusion

A circulation pump is a necessary element of modern heating systems for private houses and large objects. Selection and installation of the unit is made according to the instructions described above. The video will help you choose and install the product.