Heating security group: investigate the composition of the

What, in addition to the boiler, pipes and heating devices, should be equipped with a closed heating system with forced circulation? What are the functions of the security group in the heating system? We have to get acquainted with the list of devices, the algorithm of their choice and the order of installation.

Composition

So, it is given: we have bought a solid fuel boiler consisting of a firebox, a heat exchanger and a simple automation system, which allows to reduce the thermal power during overheating. Obviously, we will need radiators and pipes for distributing the water heated by the boiler.

What else is necessary for the normal operation of the circuit?

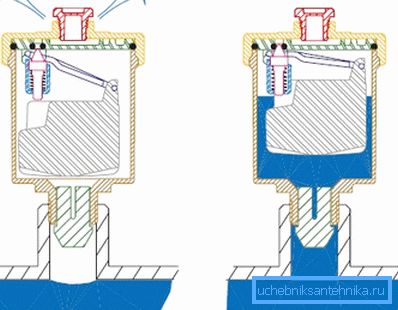

- Expansion tank. It compensates for an increase in the volume of coolant during heating. Water is almost incompressible; The tank is, simply put, a rubber balloon in a metal case. With increasing pressure in the heating system, this ball decreases in volume, allowing the tank to accommodate the excess coolant.

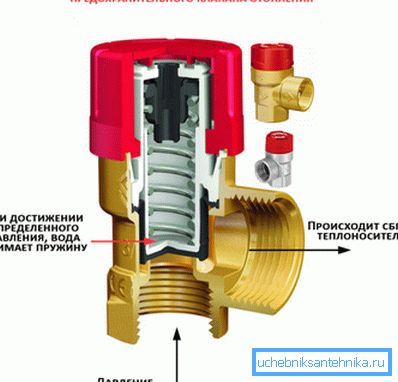

- Safety valve. It drops excess coolant in case the capacity of the expansion tank is insufficient.

By the way: actuation of the valve indicates either boiling of the coolant, which is unacceptable, or insufficient volume of the expansion tank. Instead of replacing with a larger device, an additional tank can be installed in the circuit; the volumes of several canisters are summed up.

- Automatic air vent. It removes air plugs from the system that may impede the circulation of the coolant.

- Manometer (as an option - thermomanometer). The device serves to visually monitor system parameters.

The last three devices are often sold as an assembly in a common case and are called a security group. Together with the expansion tank, they are designed to prevent the destruction of the boiler and the heating circuit during pressure fluctuations in it.

In addition to the above, for the normal operation of a closed system, the following are necessary:

- Vozdushniki (specialized elements of valves, so-called Mayevsky cranes, or ordinary water taps). They are mounted in one of the upper plugs of each heater located above the filling.

- Circulation pump, which provides the movement of the coolant in the circuit.

- A coarse filter that prevents damage to the circulating pump, scale, sand or other foreign bodies, for some reason got into the circuit.

- Optionally - valves, throttles and thermal heads, allowing to control the operation of heating devices and, if necessary, to completely turn them off one by one.

Location

At what point of the contour is it better to place each of the listed elements when mounting it yourself?

| Element | Location |

| Security group | Feed, after the release of coolant from the boiler |

| Circulation pump | Return, before returning the coolant to the boiler heat exchanger |

| Coarse Filter | Directly in front of the circulation pump |

| Expansion tank | At the site in front of the circulation pump, at a distance of at least 10 diameters of filling from the impeller |

What is the reason for such installation instructions for each element?

Security group

The pressure in the circuit reaches its maximum values just at the outlet of the boiler: when heated, the coolant expands. Hydraulic losses and a gradual decrease in the temperature of the coolant somewhat reduce the pressure with distance from the heat exchanger.

Devices that record excess pressure and discharge vapor generated during overheating, it is logical to place as close as possible to the point of maximum pressure and probable vaporization.

Pump

It is usually placed at a point with a minimum temperature. Long-term heating does not benefit the mechanics of the circulating pump for heating. As you might guess, the minimum coolant temperature will be after the passage of all heating devices - in front of the boiler.

Filter

Its main function is to protect the pump, which, in fact, leaves no special choice. The filter is installed in such a way as to catch any debris immediately before passing the impeller.

Useful: the pump and filter are usually equipped with shut-off valves. This allows you to clean the sump and remove the pump for repair or maintenance with minimal loss of coolant.

Expansion tank

The tank is placed where the flow of coolant as close as possible to the laminar. The smaller the turbulence, the smaller the pressure fluctuations in the circuit, the less chance of a false valve triggering and loss of coolant.

Vortexes are created on any bend, diameter transition, element of stop valves and, first of all, on the pump impeller.

Customization

For the two elements of the boiler strapping - the safety valve and the expansion tank - you need to select the pressure and charging pressure, respectively.

What numbers should be oriented?

- The safety valve is usually adjusted to 2.5 - 3 kgf / cm2.

- The charging pressure of the tank should correspond to the hydrostatic pressure in a fully filled circuit.

Hint: an overpressure of 1 kgf / cm2 can lift a water column by 10 meters. Accordingly, with a maximum height of the closed circuit above the expansion tank of 5 meters, the charging pressure will be 0.5 kgf / cm2, 7 meters - 0.7 kgf / cm2, and so on.

Help in choosing

Expansion tank

When purchasing an expansion tank, it is recommended to carry out an accurate calculation taking into account the expansion coefficient of your chosen coolant, temperature delta in the circuit and tank efficiency ratio, which increases with the gap between charging pressure and maximum working pressure.

However, the excess capacity of the tank will not bring any harm, and the price of the tanks differing by pitch volumes differs quite insignificantly. Therefore, usually the tank is simply taken equal to 10% of the total amount of coolant in the system.

Pump

The minimum pressure of 2 meters, characteristic of low-end models of pumps, is sufficient for a properly calculated system to work at any reasonable length of the circuit. Performance is chosen in such a way that the entire volume of coolant turns around 3 times per hour. Say, with a full volume of 500 liters, a pump with a capacity of 1.5 m3 / hour is taken.

Conclusion

We hope that our recommendations will help the reader in choosing the heating equipment for their own home.

The attached video will offer him additional information. Successes!