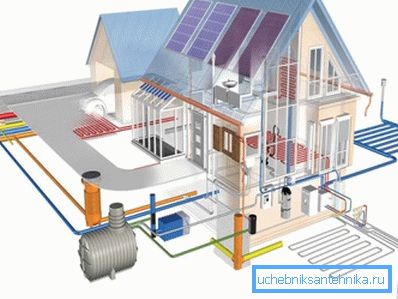

Heating water supply: sewerage: features of connections,

What ways of connecting pipes are used when sewage, water supply and heating are installed? What are the ways to connect various plumbing and heating devices? Let's figure it out.

Connections

Sewage

Gravity drainage can be collected and sealed in one of two ways:

- Embossing the sockets of cast iron pipes. The cavity between the bell and the cylindrical section of the pipe inserted into it is filled with organic fiber with resin or bitumen impregnation (cabol), compacted with coining, after which the socket is sealed with cement mortar or molten sulfur.

Useful: in the latter case, the compound is disassembled after heating with a torch, hairdryer or blowtorch. This work is done by hand strictly in a ventilated room and in a respirator or gas mask. The instruction is connected with the causticity of sulfur fumes: they are quite capable of causing complete respiratory paralysis.

- Flared connections with rubber O-rings. They are also supplied with the components necessary for the turns or branching of the network (fashion). Ring seals use:

- Pipes from gray cast iron.

- Pipes of VChSHG (from high-strength nodular cast iron, different from gray by high ductility and impact strength).

- Products made of PVC and polypropylene.

Cold water supply

Exclusively for CWS, materials differing in their low heat resistance are used: polyethylene and polyvinyl chloride. How are they mounted?

| Material | Mounting methods |

| Polyethylene | With a wall thickness of up to 4 mm, the connection is made by compression fittings. |

| With thicker walls, butt welding is used. The ends are melted by a low-temperature (200–220 ° C) heating element and pressed against each other until the polymer melt solidifies. | |

| PVC | Flared pipes under the glue joint are joined after applying an adhesive to the adjacent surfaces. |

| An alternative way to install PVC pressure pipelines is to be bell-shaped with annular seals already familiar to us. |

Heating and hot water

Heating and water supply with a working temperature up to 95 ° C can be installed in the following ways and materials:

- Black steel pipes - using gas, electric welding or threaded connections. The threads are sealed with sanitary flax (preferably with paint or varnish, which will protect it from burning out) or with polymeric materials - FUM tape or polymeric thread with silicone.

- Galvanized - only on the threads. Welding burns out a zinc coating, leaving steel without corrosion protection.

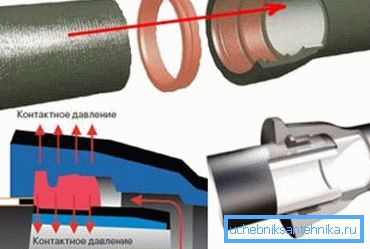

- Cross-linked polyethylene - fittings, which are a common choke - a herringbone with a fixing sleeve. The pipe is stretched by a special tool - an expander, after which it is put on the fitting; the effect of molecular memory makes it reliably compress the fitting after a few seconds.

Curiously: the price of the tool is hindering the spread of the material. It is at least 10,000 rubles for entry-level models.

- Metal-plastic - compression fittings with a split ring and a cap nut, as well as press fittings, in which the end of the pipe is crimped on the fitting with a stainless sleeve using manual or electric tongs.

- Polypropylene. Like polyethylene, it is connected by low-temperature soldering, but not with end soldering, but with the help of socket fittings. Along with them are used push-fittings, strongly resembling compression, but equipped with a spring clip to prevent accidental disassembly of the connection.

- Corrugated stainless steel. It uses the simplest compression fittings with high-temperature silicone seals.

Note: we have listed only the most popular materials for heating and water supply. We do not touch expensive exotic like copper - simply because its operational properties do not give the material special advantages over the same stainless steel at a higher cost.

Connection of plumbing and heating devices

What are the ways of plumbing water supply heating and sewage?

Sewage

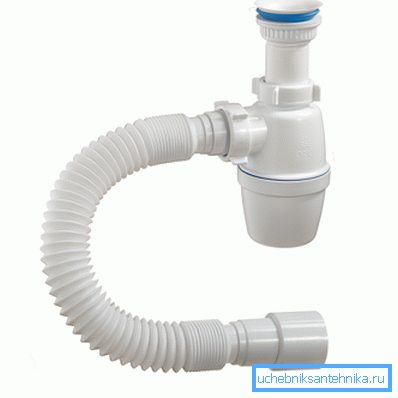

To connect plumbing fixtures to the waste system, rubber cuffs are used, which prevent not only leaks at the sockets, but also odors.

However: the corrugated tubes of sinks and sinks do not require adapters and are tightly connected to sewers with a diameter of 50 mm.

Mixers

There are only four ways to connect the mixers:

- On hard pipes for wall mounting, the usual angles are used.

- Flexible linings are forced to use water sockets with fastening on the main wall.

- Onboard installation mixers are most often connected to pipes with flexible hoses with flare nuts.

- Some outdated products of the on-board installation with tees (herringbone) can be connected to the eyeliner by connections on the threads; however, a flexible corrugated stainless pipe is increasingly being used instead.

Toilet bowls

Here the choice of options is even less.

- Most often, the tank filler valve is connected to the liner by a flexible hose with flare nuts.

- To connect flush-mounted tanks, it is common to use hard liners of any type that connect to the valve with an angle or a coupling.

Radiators, convectors

Heating devices can be connected to the supply lines:

- Through radiator plugs or adapters (for example, most aluminum and bimetallic radiators have DU25 threads, which, with the standard diameter of steel liner DU20, requires the use of a conventional adapter). Cork or adapter are driven to the radiator along the long thread; reeling tightened locknut.

- In cramped conditions or when connecting the liner to the left-hand thread, American women are often used - quick-fit fittings with cap nuts and rubber seals.

Conclusion

We hope that our miniature review allowed the reader to satisfy their curiosity. As you can see, in recent years, there has not been any special exotic on the market - everything for water supply and heating can still be bought in any store. As always, additional useful information will be offered by the attached video. Successes!