How a bath stove is made of a pipe: design and assembly

The “heart” of any bath is the stove, so its device should be given special attention. Of course, the easiest way is to purchase a finished structure, but it will be quite expensive, so you can save money and make the stove yourself. In this article, as an example, we will look at how a horizontal bath stove is made from a pipe with your own hands, since this is the simplest and most economical option.

General information

A special feature of the bathhouse furnace is that it performs several functions at once:

- Heats the air in the room;

- Heats the water that is needed for hygiene;

- Heats the stones.

I must say that according to the principle of work, the bathing stoves made with their own hands from the pipe and the factory structures are no different. Of course, more features may be present in factory products, and they have a more attractive design.

However, with careful work, a homemade stove will adequately cope with the tasks assigned to it, and will not disappoint its owners.

Features of the furnace from the pipe

Design

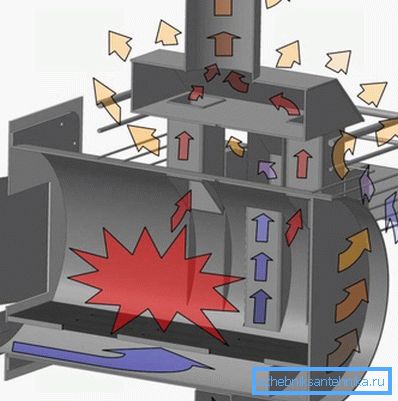

So, the construction under consideration consists of the following main elements:

- Firebox;

- The capacity located outside or inside the body, designed for bath stones;

- Ash chamber;

- A chimney that leads to the outside of the room the products of combustion of fuel.

The chambers are separated from each other by grate-grates. It should be said about such a structural element as a water heating tank. In some models it is a part of the furnace body, but more often it is located above the chamber with stones.

There are also models in which the tank is a separate element, but connected to the furnace with hoses or pipes (see also the article Truss from a profile pipe: effective systems that require accurate calculations).

Homemade bath stoves from the pipe are horizontal and vertical. The first ones are preferable because they burn out longer and at the same time can warm up the room faster. Therefore, below we consider the manufacture of exactly vertical design.

Merits

Of course, bath stoves from a pipe are far from the only design option that can be performed independently, but they have a number of advantages, among which the following points can be highlighted:

| Good resistance to high temperatures | Due to the properties of steel. |

| The ability to quickly heat the bath | Even the simplest homemade ovens can warm a bath in 40-90 minutes (time depends on the ambient temperature). |

| Easy installation | Unlike brick constructions, any person who knows how to handle a welding machine and other tools for metal can assemble a metal furnace. |

| Low price | The purchase of materials does not require strong costs, and if there is a suitable piece of pipe in the farm, then the furnace will be generally free of charge. |

| Durability | If the design will be executed qualitatively, then it will be able to serve more than a dozen years. |

| Low weight | Due to this, the construction of metal does not need to build a foundation, unlike the brick counterpart. |

disadvantages

Along with the advantages, metal products also have disadvantages, however, there are only two of them:

| The design quickly cools | For this reason, in the process of receiving the bath, the stove must be constantly heated. |

| The room heats up unevenly. | This disadvantage is noticeable only in baths with a large area. |

Tip! In large saunas, experts advise installing several stoves, which will avoid uneven heating.

Furnace manufacture

Instructions for the manufacture of a horizontal furnace is as follows:

- The first step is to prepare a pipe with a diameter of at least 0.5 meters and a length of about 0.8 meters. The edges of the pipe must be carefully aligned.

- Then, from a sheet of metal with a thickness of 10–12 mm, it is necessary to make a grate area, which is a rectangle of 80x40 cm in size. In the area, you need to cut a hole and attach rods to it or use industrial grid bars.

- When the grate is ready, it must be welded to the walls inside the pipe. At the same time it is necessary to ensure that the pipe seam is under the platform, which will allow to increase the life of the product.

- End walls should be made of sheet metal. Outwardly, it should be a rounded rectangle. The height of the part must be 70 cm and width - 60 cm.

- Next, in the facade you need to cut two rectangles - these will be the doors of the blower and the combustion chamber.

- After this, the back wall is made in the form of a rectangle measuring 70x90 cm. The upper part of the wall will serve as a stopper for the heater, which is located outside.

- Then it is necessary to weld the facade and the back wall to the pipe.

- Then in the middle of the pipe (outside), it is necessary to weld the front stopper of the heater, which should follow the contours of the pipe from the bottom, and the contours of the rear wall from above.

- In the upper part of the body, a hole with a size of 15x15 cm should be cut out. A sheet of metal furnace with a hole for the chimney is mounted above it. Moreover, the hole should be shifted by 10-15 cm to the facade, which allows to ensure the conditions of complete combustion of fuel.

- The field of this is welded to the roof of the chimney.

- Further, to increase the walls of the stove, grilles 15-20 mm high are welded to its stoppers.

- The next step is to install the ash pan door and the combustion chamber.

- To the back of the product must be welded shelf for water tank. The size of the shelf depends on the size of the tank.

- At the end of the work, the structure must be machined with a grinding wheel in order to remove rust and scale. After this procedure, the product can be coated with heat-resistant polymer paint and heated to bake the paint (the procedure is performed outside the room).

Tip! Before starting work, it is necessary to make sure that the pipe for the bath stove is of high quality, i.e. has no signs of corrosion. The quality of the future product depends on it.

In this work on the manufacture of stoves for a bath completed. Now you can install the product and operate it.

Conclusion

Having figured out how to make a bath stove out of a pipe, it is really not difficult to cope with this task. Moreover, the product will be safe and with a sufficiently high efficiency. The only thing is to perform all the above steps carefully, without violating the technology (see also the article Ladder from a profile pipe: how to make a light and solid construction).

From the video in this article, you can get more information on this topic.