How are electric and solid fuel boilers proterm and their

Successes of gasification do not yet allow completely to abandon solid fuel boilers not only in the “outback” of our country, but even in the Moscow region. There are holiday villages and settlements, where the “blue fuel” is promised to be held soon.

Today we will talk about solid fuel and electric boilers «Protherm» (Slovakia), which will help make the temperature in the house as comfortable as possible. You can use them in a joint scheme, complementing each other, or you can separately.

The article will be built in this way - first we will tell about a typical representative of devices that use solid fuel (coal, wood or peat), and the second part will be devoted to electric boilers. Although the latest heating boilers Proterm and more expensive, but at certain times, say at night, they are indispensable.

Solid fuel boiler "Proterm"

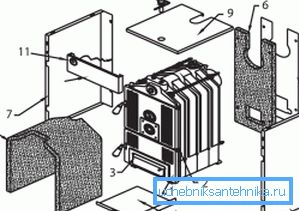

The Protherm Bober model reviewed today in the review has a cast iron heat exchanger that endures corrosion processes and has shown itself to be perfectly in an aggressive gas environment and high temperatures. You can use coal and firewood in your device.

The heat capacity of the equipment depends on the number of sections that were used to assemble the heat exchanger, usually 4-8, so it can be 18-48 kW. This also determines the maximum length of the logs - 320-680 mm.

Remember that the specified nominal heat output can be achieved with a moisture content of wood not exceeding 20%.

Device control

For example, the Bobor boiler has 3 fuel combustion controls:

- mounted on the fuel door air fungus and chimney flap designed to adjust their own necessary traction equipment;

- thermomechanical power regulator - to automatically adjust the air supply to the combustion chamber, depending on the temperature of the coolant leaving the device’s water jacket.

For example, when the coolant begins to lose temperature relative to a given parameter, the power control opens the valve installed on the blower door. This increases the flow of air into the combustion chamber and increases the intensity of combustion, which leads to an increase in its temperature. And vice versa.

Heat loss and power

When choosing equipment, it is necessary to take into account that the declared capacity corresponds to the heat loss of the heated building:

- in case of its shortage, its cooling will begin and discomfort will be felt;

- excess - reduces the performance of the boiler, it begins to intensively develop the processes of resin formation, which impair heat transfer, and also a large amount of condensate is formed, which can lead to corrosion.

And in fact, and in another case, this greatly affects the durability of the heating device.

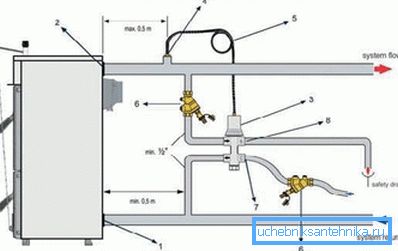

Tip: the safest and most optimal scheme for connecting a solid fuel boiler to the heating system is considered to be through an accumulating tank. It makes it possible to operate the equipment with maximum efficiency, but sparingly due to the fact that its operation does not depend on the consumption of heat energy by the system.

Where applicable, the pros and cons of devices

Solid fuel boilers are designed to work in heating systems with mechanical and natural circulation. The exception is equipment with a capacity of 39 and 48 kW. It is used only in forced heating systems.

Tip: to protect the devices from overheating in a closed room heating system, you should install a special safety valve that can add cold tap water to the equipment in an emergency, and remove excess hot water through the sewer system. In the open, such protection does not apply.

It is possible to use the boiler not only for heating, but also for hot water supply. In this case, a cumulative boiler is built into the heating system.

Do not forget that the design of solid fuel boilers, including the “Beaver”, does not provide for a built-in expansion tank for heating, a safety valve and other elements of the strapping. Therefore, the instruction permits them to be connected only to domestic and industrial heating systems, where they are provided.

Model units will be the ideal heating device for woodworking enterprises.

In this case, you can get two benefits at once in one device:

- heat the building;

- dispose of waste products - sawdust and shavings.

In places far from gas supply, as well as where there are interruptions in the supply of electricity, the Proterm solid fuel boiler can become the only source of heat.

| Benefits |

|

| disadvantages |

|

Overview of models

In the domestic market, two groups of solid fuel boilers “Proterm” are offered:

- Kapibara Solitech Plus - a classic version. Power on the wood - 13-48 kW, on the corner - 17.5-70 kW. Of the advantages of the model are:

- a large range of products allows you to choose equipment for any room;

- compact modern design has a pleasant appearance, highlighting the model among analogs;

- maintenance does not create problems;

- high efficiency due to the 3-way circulation of smoke in horizontals;

- during operation, heat loss is minimal.

Connection:

- installation and connection to the chimney must be made with regard to TB;

- when choosing a chimney, it is imperative to follow the traction parameters that are stated in the passport for each model;

- boiler operation is allowed only after complete installation of the hydraulic system and its crimping.

- Bober DLO - the inner part and body are made of cast iron. The operation mode makes it possible to change the heating temperature. Benefits:

- simple installation;

- low-cost maintenance;

- large volume of the combustion chamber;

- during operation, the heat loss is small;

- exhaust gas is conducted through a horizontal duct, which allows to increase the efficiency.

Used for heating residential and industrial premises with a forced or natural circulation system. Fuel - wood with a moisture content of up to 20% or fine-grained coal fraction of 40 mm. It is allowed to combine the model with a gas or electric boiler.

Electric boiler "Proterm"

A good alternative source of heat in a private house can be electric boilers Proterm. They are also able to provide the cottage with hot water.

Their main advantage is that during work they do not release harmful substances into the atmosphere, so they can be used in residential premises. Installation of equipment does not require the installation of a chimney and a special ventilation system, which significantly reduces the cost of operating such equipment.

Protherm skat

Elegant equipment for heating and hot water. The equipment belongs to the household class and is able to provide warmth of a one-story private house or apartment. During operation, the device is almost silent, settings and controls are easy.

Let us consider in more detail:

- food - from the electric power;

- installed on the wall;

- connect to the heating system;

- appearance of the actual wall equipment;

- the navigation screen interface is ergonomic and simple;

- power is evenly distributed on the heating elements;

- can be connected to a variable 3-phase network;

- 6K and 9K models will connect to 220V / 50Hz;

- Efficiency devices - about 99.5%.

Conclusion

The use of solid fuel boilers "Proterm" provides an opportunity to get full autonomy and independence from gas and electricity. At the same time, electric Protherm boilers do not worry about burning fuel during the night and can maintain the optimum coolant temperature, although they depend on the supply of electricity.

By combining two of these heating units in a house, you can make living in it in a cold time as comfortable as possible. The video in the article will help you find additional information on this topic.