How are solid fuel boilers don used and what is their

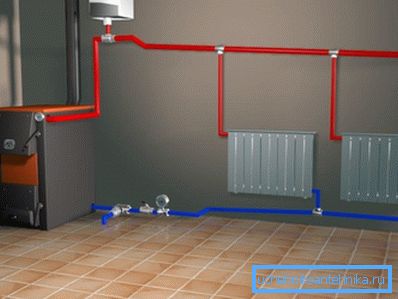

As an autonomous heat generator for the heating circuit and hot water supply of a country house and cottages, a solid fuel boiler is well suited. He works on a variety of fuels - wood, coal, peat, briquettes and pellets.

You can also adapt it for burning gas or diesel, which further confirms the versatility of the device. Domestic boilers "Don" of the plant "Conord" firmly occupied the niche of high-quality equipment at an inexpensive price.

What does the manufacturer offer

- Models KS T 16 (16 kW) and KS TV 31.5 (31.5 kW) are designed to work exclusively on solid fuel. Accordingly, they can heat the rooms and buildings up to 160 m2 and up to 310 m2.

- Universal model KS ТГВ 16-20 has a gas burner and a coil included. Able to work on solid fuels and gas, in the latter case, the power of the device reaches 20 kW, which allows heating up to 200 m2.

On solid fuel, the equipment efficiency reaches 75-76%, which is a good result. Able to achieve it through a specially designed firebox and a unique water shirt.

In the latter, water is evenly distributed throughout the boiler body, and an 8 mm layer of heat insulating material retains its heat for the heating system. Therefore, the coolant does not spend extra energy on heating the environment and heating the surface of the device.

Steel - the body and the combustion chamber have a thickness of 3 mm, which ensures durable equipment operation, even with its intensive functioning. The lifetime of the device, declared by the manufacturer, is 15 years.

The solid fuel boiler DON, thanks to a large firewood, is able to function autonomously on one tab of firewood for up to 8 hours. You no longer need to be distracted from business to throw firewood. The equipment has all certificates of compliance with safety standards.

Merits

Let us consider in more detail the possibilities of the heating device:

| Hot water | In the line of equipment in addition to single-circuit heating boilers, there are two-circuit. They are able to provide living with hot water of 390-740 l / h. |

| Versatility |

|

| Non-volatility | Heating boilers Don all model range does not need electricity. Therefore, interruptions in power supply can not affect their performance. You can be sure that even if the house power is turned off, the heat will be fed to it at the same pace. |

| Additionally | Indisputable advantage of floor boilers:

|

Efficiency and reliability of equipment

One of the main parameters influencing the choice of the heating device is its efficiency. In our case, it is close to 75%, and in some cases surpasses it, which is considered an excellent indicator. Thus, the cost of operating the device is reduced.

When determining the efficiency of the considered heating equipment, we recommend to pay attention to its following features:

- the presence of thermal insulation between the lining and the heat exchanger, which prevents unproductive loss of thermal energy;

- how large is the surface area that heats the coolant products of combustion.

Tip: more economical are heating devices, the sum of the surface areas of the heat exchanger which will be more.

Reliability should be understood as the ability of equipment to function reliably in our special conditions, which should include:

- gas pressure fluctuation in the range of 0.6-2.0 kPa, alas, is not uncommon;

- lack of electrical energy. Usually, domestic devices of this type do not require connection to the mains, at the same time, imported ones in most cases do not work without it. For them, you need to purchase additional UPS;

- quality manufacturing of the necessary controls.

The following parameters are taken as the boiler safety criteria:

- to what temperature the outer surfaces are heated. It is considered safe up to 50? C, which can contribute only to the layer of insulation between the casing and the shell;

- how the automation is protected from mechanical damage during operation of the equipment, because of which the setting may be lost or it may completely fail;

- is it possible to diagnose the device;

- reliability of controls.

Tip: we recommend to purchase only such devices where the controls have maximum protection against various damages.

When choosing, pay attention to the presence of a thermometer that indicates the temperature of the coolant inside the boiler. If gas is used as fuel, the heater must have automatic equipment that prevents boiling of water and turns off the gas supply when there is no traction or when the pilot burner goes out.

Convenience and safety of operation

In this case, implies the possibility of smooth implementation:

- ignition - in most cases it is carried out with the help of a spike and does not cause difficulties;

- diagnostics - should be provided with a visual control over the temperature of the water inside the stake;

- settings - requires clear instructions on how to control the automation, and controls should be conveniently located;

- prophylaxis - conducting an inspection of the gas burner device, cleaning the fire tubes, easy access to different nodes and their unimpeded removal if necessary.

Conclusion

Solid fuel boilers Don are manufactured in accordance with the quality manual and company regulations. Particularly important operations - equipment pressure testing and welding, are performed by workers with a personal stamp, which increases their level of responsibility for the output (see also the article Solid fuel boilers KCM: simplicity, reliability and efficiency).

The devices are economical, reliable, convenient and safe to use. Video in the article will provide an opportunity to find additional information on the above topic.