How do pellet boilers of different types of heating work?

Boilers designed for burning pellets are classified as modern heating equipment. They are widely used abroad, especially in European countries. This method of space heating, based on burning solid granulated fuel, is gradually becoming popular in our country. Meet the homeowner, marching in step with the times already possible not so rare. In most cases, the transition to solid fuel boilers for pellets is due to economic benefits and concern for the environment.

Types of equipment

The design of the boiler of this type consists of a fuel chamber and a bunker, where fuel is loaded. There is equipment intended only for burning pellets, and there is also a combination, in which other solid fuels can be used. While the price of both of them is quite high. From the bunker the pellets enter the fuel chamber with the help of an auger.

There are 2 types of boilers that have their pros and cons in operation:

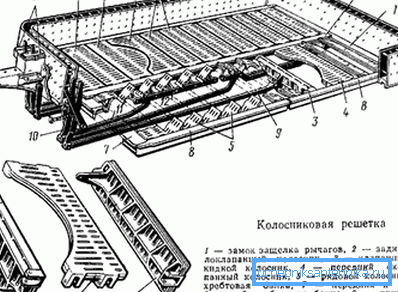

| With grate |

|

| With retort burner |

|

How the boiler works

Consider the option with a retort burner:

- Fuel must be put into the boiler bunker as it is emptied with its own hands or in automatic mode.. Depending on the capacity of the boiler, the volume of the tank and the flow rate, this can occur once every few days or less. In addition, there are other options:

- pellet-fired heating boilers with a large-sized outboard bunker, which is installed in a separate room. In this case, it can be replenished even once a season;

- in which compressed air is used to deliver fuel. This makes it possible to install the bunker at a considerable distance from the boiler.

- After that, the fuel enters the pipeline with an installed auger, through which it begins to flow into the combustion zone.. In the retort version, for complete combustion of the fuel, as well as to keep the bowl from overheating, primary air is supplied here.

At the same time, the secondary pumped through the holes of the retort or others, specifically designed for this purpose. This is due to the fact that in atmospheric conditions, pellets only smolder, but with the help of forced air supply it is possible to make them burn intensely.

- Ash is gradually crumbling through the edges of the burner, because fresh fuel periodically flows from below.. The traditional boiler is equipped with a fixed bowl, but there are those where it can rotate. This equipment can burn pellets that are high in dust, wet sawdust, crushed fine coal and chips. Ash in this case is removed from the combustion zone more efficiently.

Tip: in boilers where a fixed burner is installed, it is better to burn only high-quality pellets.

- Heat released during combustion heats the coolant passing through the heat exchanger of the boiler. Exhaust gases escape to the atmosphere through the chimney pipe.

Modern boilers almost 90% of the heat generated give the heat carrier, thus achieving a high efficiency of the heating system. From the burning of biomass, ash remains a small amount, so it is usually removed from the boiler infrequently. In some models this happens automatically with the help of a screw.

Operation and maintenance of equipment

This boiler is an automatic device that does not require special maintenance. The owner only needs to load the bunker with fuel in time, control the temperature parameters and remove the ash.

Such equipment can function for a long period without operator supervision. There are models of boilers produced recently, where the cleaning of the surface of heat exchangers from ash and dust, gradually accumulating on it, occurs automatically.

Tip: In traditional equipment, the manual requires manual maintenance of such prophylaxis at least once a month, so as not to impair heat transfer.

To adjust the intensity of fuel combustion, a combined method is used - they add its supply to the combustion chamber and inject more air into it, which contributes to their more complete combustion.

Some models of boilers are offered in which a heat-resistant ceramic burner is installed that can withstand temperatures of 1000? С. In this case, high-quality pellets burn without the formation of smoke and ash.

There are models with a vertical heat exchanger, which does not allow accumulation of dust and soot on the surface. In this case, the ash, crumbling, falls into a special bunker. Boilers of this type do not require periodic cleaning of heat exchangers and chimneys.

Conclusion

The constant rise in prices of petroleum products and natural gas leads to the fact that these types of fuels are beginning to compete with others, in particular pellets made from waste wood processing industry. The developed equipment can work for a long time in an automatic mode, which makes it comfortable to use.

Owners can only choose the right capacity and periodically fill the bunker with fuel. The video in the article will help you find additional information on this topic.