How to choose a bimetallic radiator: design, advantages and

The choice of bimetallic heating radiators must be conscious and correct, because the comfort of your home depends on it. We will consider the main characteristics and features of the devices, compare them with competitors and understand how to choose the right bimetal radiator.

Features of bimetallic radiators

Design

First of all, it is necessary to understand what is a bimetallic radiator and what is its design. Like most batteries of other materials, the product is a system consisting of two collectors connected by tubes.

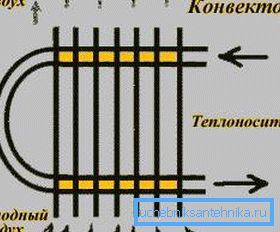

The heat-transfer agent most often gets into the upper collector, from where it begins to move along the internal channels and fill the device. In the end, the fluid enters the outlet opening connected to the return pipe of the heating system.

In order to maximize heat transfer, manufacturers have tried to increase the area of contact between the battery case and the air. To do this, aluminum plates are pressed on the tubes, which quickly heat up and participate in heat transfer.

In addition to direct heat transfer and infrared radiation, gas convection under the influence of gravity plays an important role in the operation of the device. To enhance it, the casing ribs are made in such a way that they create channels for the movement of heated gas layers. The distance between the plates is chosen so that the air flow was not laminar, but turbulent, as this increases the intensity of the interaction.

Collectors with tubes, in turn, are divided into prefabricated sections. This allows you to quickly and easily pick up the device of the desired size.

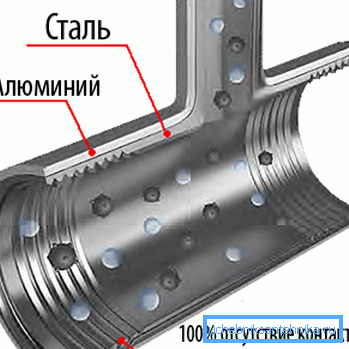

If we consider the design of the aluminum or cast iron radiator, we will not see significant differences. The fact is that the main difference between bimetallic convectors consists not in the construction as such, but in the materials used: they consist of two metals - steel and aluminum (sometimes copper and aluminum).

Inside the aluminum case there is a steel core, which is able to withstand pressures up to 40 atmospheres and is not afraid of a heat carrier with high acidity. As a result, we get a device with the strength of a cast iron battery and the heat transfer of an aluminum convector.

Note! The main difference of the bimetallic device is the use of two types of metal, which provide high strength at maximum heat transfer.

Benefits

To better understand how to choose a bimetallic radiator, consider the advantages that it has, and try to determine what they depend on.

Here is a list of the main benefits of using bimetallic batteries:

- High hydraulic and mechanical strength. This feature is due to the use of high-strength steel core, which is able to withstand pressures up to 40 atmospheres;

- Lack of electrochemical corrosion. The entire internal surface of the radiator channels is made of anticorrosive steel, which, unlike aluminum, does not place high demands on the coolant and is not afraid of high acidity. Contact of the heat carrier with aluminum is absent, therefore galvanic processes in the system are not observed;

- High heat emission. The thin-walled core is pressurized with an aluminum casing, and the thermal conductivity of aluminum is four times higher than that of steel. As a result, the efficiency and efficiency of the device becomes noticeably higher than that of single-component steel and cast iron units;

- Small section capacity. Due to the small capacity of the coolant apparatus has become lighter, in addition, its thermal inertia is minimal. This facilitates installation work and increases the efficiency of temperature control through the use of thermostatic valves and heads;

- Long service life. Some manufacturers give a guarantee for 20 years, the actual use allows you to count on 30 - 40 years of normal operation of products;

- Attractive and modern design. The body is made of aluminum, which lends itself well to figure casting and allows you to create beautiful modern products;

- Pretty easy do-it-yourself installation.

The disadvantages of the model can be attributed to the relatively high price. Also important is the absence of assembly flaws.

Note! A huge role is played by the quality of manufacture and assembly of products. The joint use of steel and aluminum requires strict adherence to SNiP and GOST, because otherwise the device will not meet the expected qualities.

Choosing a radiator

As we could see, the quality of bimetallic devices depends primarily on the quality of their manufacture and assembly. The remaining benefits are already incorporated in the design features and materials used.

The quality of manufacture and assembly depends on the culture and level of production, so the important question is the correct choice of manufacturer. What company bimetallic radiators to choose?

Here it is difficult to give a definite answer. The highest quality distinguished Italian, German, French and Scandinavian companies. These are manufacturers such as Radena, Global, Tenrad, Sira, Oasis, Royal Thermo, etc.

Manufacturers from Eastern Europe, including the Russian and Ukrainian firms Rifar and Altermo, showed themselves well.

Finally, there are many Chinese companies (well, without them), which, despite the fixed stereotype, are quite worthy of attention. These are Epico, Grandini, Shark, Maxterm and many others.

Note! Before choosing a manufacturer, study its website, read customer reviews, consult with those who have experience in using bimetallic devices.

Conclusion

To choose a good bimetallic heating device, you should study the features of this product group, as well as learn about the manufacturers that are most represented on the market. The video in this article will help you not to be mistaken.