How to choose a gas boiler for heating: get acquainted with

This article is about how to choose a gas heating boiler. We will find out how the thermal capacity of the product is calculated, and we will get acquainted with the classification of modern gas heating equipment. Our material does not contain final recommendations: the purpose of writing is to help the reader navigate the variety of market offers.

Thermal power

The main parameter of any heating equipment is its heat output. How to calculate the need for it for a house with known parameters?

The most universal formula that takes into account the coefficient of insulation of the building. It makes it possible to estimate the need for heat in buildings with non-normalized thermal resistance of the enclosing structures (in other words, insulated very well or very poorly).

It has the form Q = V * Dt * K / 860.

What is behind the variable notation?

- Q - thermal power. The formula allows you to get the calculated value in kilowatts.

- V is the total volume of the space in cubic meters.

- Dt is the calculated maximum temperature difference between the room and the street.

- K - coefficient of insulation.

Two parameters need comments.

Dt is generally calculated as the difference between the temperature of a dwelling (+ 18-22 C) recommended by the SNiP and the average temperature of the coldest five-day week in the last few years.

Please note: if the house is planned to support, say, +25 or +30, the parameter is adjusted accordingly.

The coefficient of insulation is taken from the table below.

| Coefficient | Warming |

| 3 - 4 | Laying of the walls in half-brick without exterior finish, single-layer glazing |

| 2 - 2.9 | Brick walls, double glazed wooden frames |

| 1 - 1.9 | Bricklaying in a half brick, single-chamber double-glazed windows |

| 0.6 - 0.9 | Foam or mineral wool wadding, triple glazing with energy-efficient glass coating |

Let us, as an example, calculate the need for heat in a house measuring 10 * 10 * 3 meters, located in the town of Shimanovsk, Amur Region, provided that the temperature is maintained at +25 C.

The walls of the house with a thickness of one and a half bricks are insulated with 150 millimeters of foam; windows - with double glazed windows.

- The volume of the building is 10 * 10 * 3 = 300 m3.

- Data on typical winter temperatures for any city is easy to find in the well-known Internet encyclopedia. The average minimum of the coldest month is -32.5 C. It has become, Dt = 25 - -32.5 = 57.5 degrees.

- The quality of the insulation of the house is close to the maximum possible, so the coefficient of insulation can be safely taken equal to 0.7.

- Calculation, thus, will look like 300 * 57.5 * 0.7 / 860 = 14 KW.

Nuance: when choosing a particular model, the heat output is always rounded up. All modern gas boilers are equipped with thermostats, so that excess capacity will mean only a little longer pauses in operation; Meanwhile, at the peak of cold weather, the extra 1-2 kilowatts may turn out to be more than not superfluous.

How does the choice of a gas boiler heating for power - we found out. What other options should I pay attention to?

Installation method

In the outdoor version more often you can find devices of significant (from 50 KW to 2 - 5 MW) power. However, there are exceptions: in the assortment of many third-tier manufacturers there are extremely cheaper outdoor models that give only 7-10 kilowatts of heat.

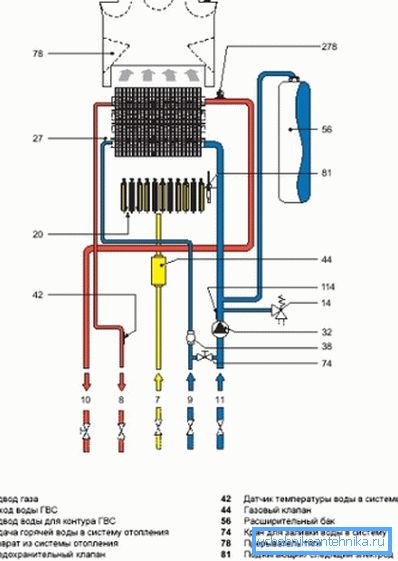

The most prominent feature of the floor heating domestic boiler is that it is only a burner, a heat exchanger and a system for automatically adjusting the temperature of the heat carrier; the safety group, the expansion tank and the circulation pump are mounted separately.

For wall-mounted products, on the contrary, moderate (not more than 100 KW) power is typical and the manufacturer presets at least the safety group and the circulation pump, and often the expansion tank directly into the boiler body. In fact, we have a miniature boiler room: to get started, all you have to do is connect the device directly to the contour, without any additional strapping elements.

Heat exchanger material

Floor boilers

For outdoor boilers characterized by the use of steel and cast iron heat exchangers.

- The first ones are used, in particular, in industrial installations and due to high operating temperatures they allow reaching enormous values of thermal power.

- A distinctive feature of the second is a significant mass, which compensates for the moderate mechanical strength of cast iron, and a limited operating temperature. Cast iron heat exchangers of large capacity boilers are often supplied by manufacturers as separate sections and are assembled on site - precisely because of the enormous weight.

Wall mounted boilers

Here, too, two options are possible.

- Steel heat exchangers are used in this case. Actually, they are equipped with most of the products of the lower and middle price ranges.

- Copper is used along with steel. It imposes even more severe restrictions on the temperature of the flame than cast iron; but the highest thermal conductivity of the metal makes it possible to make the heat exchanger more compact with the same heat output, which makes it possible to reduce the overall dimensions of the boiler.

Functionality

The so-called single-circuit boiler has a single heat exchanger and is intended solely and exclusively for heating the coolant.

Bypass products, in addition, are able to provide a house with hot water.

Water can be heated in them in three ways:

- In a separate plate heat exchanger. It is attractive because it allows the repair of the DHW circuit without affecting the heating functions.

- In coaxial (pipe in pipe) bithermic heat exchanger, where the DHW is heated from the coolant.

It is curious: in double-circuit boilers with flow-through heaters, simultaneous operation of hot water supply and heating, as a rule, is impossible. When the hot water is open, all the power of the boiler is directed to its heating.

- In the built-in storage heater of indirect heating, heated again by the coolant flow.

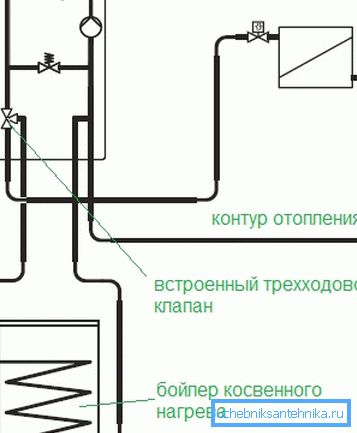

By the way, an external indirect heating boiler can be connected to a single-circuit boiler. With a certain configuration of the strapping, it will perfectly provide the house with hot water outside the heating season; in this case, the coolant circulates in a small circle - between the boiler and the boiler.

How to choose a heating gas boiler in terms of functionality? Which scheme is preferred?

This is the rare case when the author allows himself to give quite clear advice. Our choice is a product with a storage water heater (boiler), indirect heating.

On which scheme it is better to stop: on a single-circuit boiler with an external boiler or a double-circuit with a built-in one depends solely on the dimensions of the room. Separate devices will take up more space.

What is the reason for such a peculiar instruction? After all, the flow heater is much smaller than the storage heater, isn't it?

That is true, but the boiler provides a stable hot water temperature, unlike a competing solution. In the case of a flow-through heater with automatic adjustment of the burner flame, an attempt to take a shower comes down to a continuous fight against the mixer taps. Believe me, this is very inconvenient.

Traction

It can be natural and forced.

Natural

The so-called atmospheric (open) burners with natural flue take the air directly from the room where the heating equipment is installed, and divert the combustion products into the chimney or ventilation duct. The only serious advantage of the scheme is energy independence: it can work where there is no electricity.

The disadvantages are much more.

- In an apartment building with apartment-based heating, the operation of such equipment is usually impossible in principle. Ventkanal simply will not miss the flow of combustion products from five to ten boilers.

- When working in the summer heat, a boiler supplying a house with hot water will additionally heat the room by heating the chimney.

- Finally, the use of equipment with atmospheric burners imposes stringent requirements on ventilation and the size of the room. In particular, its volume should be at least 15 cubic meters; each kilowatt of boiler capacity adds to this number another 0.2 m3. Mandatory window and clearance under the door for air flow from other rooms.

Forced

A closed burner (the respective boilers are often called turbocharged or supercharged ones) takes the air from the street and removes the combustion products there as well. For this purpose, two separate air ducts can be used or, more often, one coaxial one. In the latter case, the incoming air passing through the outer shell cools the combustion products and prevents the heating structures of the house from heating.

Traction provided by the fan. Accordingly, an external power supply is required for operation of a closed burner. In addition, the turbo burner involves the installation of the boiler only and exclusively on the outer wall.

Useful: it is recommended to mount the coaxial air duct with a slight inclination to the inner side and complete the condensate collector. Otherwise, freezing of condensate in extreme cold can completely block the pipe.

Ignition

Piezo ignition

Most of the devices manufactured in Russia and Ukraine belong to the non-volatile type and are equipped with piezo ignition.

How does he work?

- Pressing the button is transmitted to the piezoelectric element and causes air breakdown between the contacts when a significant potential difference occurs..

- Spark ignites igniter (pilot burner), which burns all the time of the boiler.

- Depending on the temperature of the coolant, the thermostat periodically opens the gas supply to the main tubular burner, which ignites from the igniter and heats water or antifreeze in the circuit.

- Simple bimetallic protective mechanisms shut off the gas supply when the coolant is overheated and the pilot burner flame goes out.

This scheme has no alternative where there is no constant power supply. However, it implies a low degree of automation; in addition, a constantly burning igniter consumes up to 20% of the total gas consumed by the boiler.

Electronic

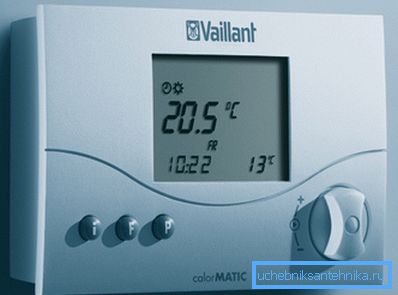

Volatile ignition option allows you to:

- Abandon pilot burner. The main burner ignites high-voltage discharge.

- Use additional automation tools: GSM control, weather monitoring, remote temperature sensors, etc.

The electrical part of the equipment - fans and control electronics - consumes up to 120 watts of constant power.

How to choose gas heating boilers according to the type of ignition? The answer is obvious: electronic ignition is preferable where there are no long interruptions in electricity. Short-term shutdowns will not become a problem: in order not to sit in the cold without heating, it is enough to connect the boiler with your own hands through a UPS with a sufficiently capacious battery.

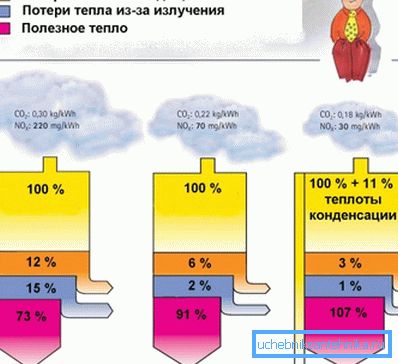

Convection and condensation

It would seem that the basic scheme of gas heating equipment is simple and clear: the flame gives off heat to the heat exchanger through which water flows; It heats up and transfers heat energy to radiators. Under ideal conditions, the efficiency of such a system can reach 95%; the remaining 5% is carried away by hot combustion products.

However, gas boilers can be found on the market, for which the efficiency of 107 - 109% is announced. Yes, their price is unlikely to appeal to an economical buyer; but they exist. Did the industrialists invent the perpetual motion machine?

Alas, manufacturers are a little cunning. The main products of the combustion of volatile hydrocarbons are carbon dioxide and water. Accordingly, the boiler leaves the warm air, saturated with water vapor.

In the case of the traditional boiler - the so-called convection - manufacturers artificially limit the temperature of the coolant on the return line to a minimum value of 55 ° C to avoid moisture condensation on the heat exchanger. In addition to steam and CO2, the condensate contains traces of organic acids, greatly reducing the life of metals with low corrosion resistance.

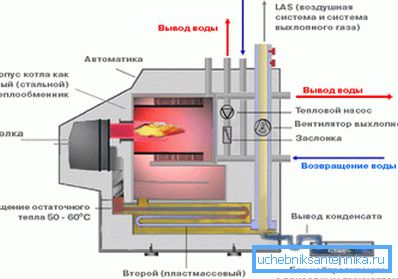

But manufacturers of condensing boilers go the other way:

- The additional heat exchanger is cooled to 30-40 ° C and is made corrosion-resistant.

- About him organized drain condensate into the sewer.

Why is all this necessary? Then, so that the phase transition between water vapor and water that occurs with energy release gives the economizer (low-temperature heat exchanger) an additional 10-12% of heat. As a result, the efficiency of the device can indeed exceed 100% if one takes for them the full heat of combustion of the gas.

How to choose gas heating boilers according to the work scheme used? To be honest, the efficiency of a condensing boiler does not play a decisive role: it is much more expensive than a convection boiler, and for a small house the payback period will be at least 7-10 years.

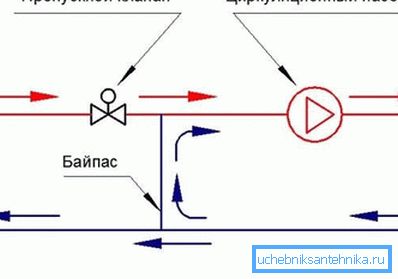

But the ability to use it with low-temperature heating without complicated temperature matching schemes is a definite plus. Usually, the cherished 30-40 degrees required for the operation of a water heated floor are obtained by installing an additional circuit with its own pump and a thermostatic valve dosing the flow.

Conclusion

We hope that the information provided to the reader will help him make a good choice. As usual, the attached video will offer additional thematic materials. Successes!