How to choose a heating boiler: practical advice and

In this article, we will tell you about the criteria for selecting a heating boiler. Moreover, we consider what modifications this equipment is presented on the market.

The topic of the article is of considerable interest both for owners of country houses and for owners of city apartments. Indeed, sooner or later it becomes clear that central heating is expensive and impractical. At the same time, autonomous heating of housing saves money without affecting the comfort of living in a heated room.

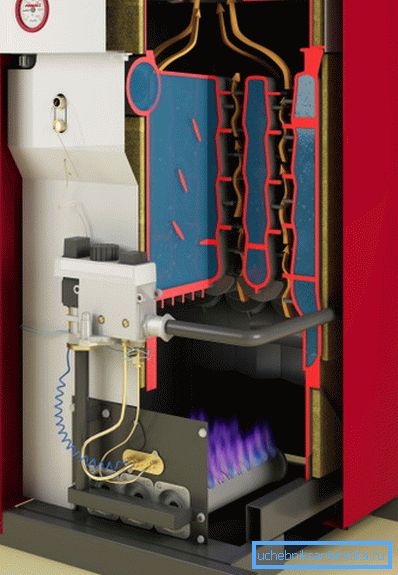

The heart of any autonomous heating system is the boiler. This device is designed to burn a particular type of fuel and to heat the coolant. Steam or water is most often used as a heat carrier. In regions with particularly harsh climatic conditions, antifreeze is used as a coolant.

Main selection criteria

If you are faced with the question of which heating boiler to choose for operation in a country house, you should take into account the following characteristics:

- nature of exploitation of a country house (seasonal or all-season);

- remoteness of the construction site from the gas distribution pipeline;

- the quality of the power supply and the power that the home wiring is able to withstand;

- construction site area;

- number of rooms;

- the type of previously operated system and the characteristics of the existing pipeline and radiators;

- type of chimney and ventilation system in the house;

- the presence of a separate room that can be used as a boiler room;

- availability of utility room or extension for fuel storage equipment;

- availability of access roads to the construction site for fuel supply;

- budget allocated for the purchase, installation and subsequent operation of equipment.

Equipment classification

You do not know which heating boiler to choose for a country house? To begin with, let's try to determine what the classification of this equipment is.

Boilers designed to heat individual housing construction projects are classified according to the following distinguishing features:

- type of fuel used;

- the ability to heat only the coolant or at the same time the coolant and water used for household needs;

- dimensions and configuration;

- degree of automation equipment;

- coefficient of performance (COP);

- coolant pressure;

- coolant temperature range;

- hydraulic resistance;

- power rating

After we have decided on the selection criteria, we will consider how to choose a boiler for heating a private house.

Selection according to the type of fuel used

Modern boilers in accordance with the type of fuel consumed are divided into the following modifications:

- gas;

- liquid fuel;

- solid fuel;

- electric.

We will determine the advantages and disadvantages of each of the listed categories.

- Natural Gas Units, are becoming increasingly common, which, incidentally, is not surprising, since they are distinguished by their low price and relatively low maintenance costs.

The main advantage of such devices is the affordable cost of natural gas, which makes heating a country house advantageous. On the other hand, this advantage sometimes turns into a disadvantage, since many suburban buildings are located far from the gas distribution pipeline.

Modern gas boilers are mostly automated, and therefore can be used with minimal human involvement.

- Fuel oil heating units they are used less and less, and there are a number of objective reasons for this.

First of all, for the operation of such equipment it will be necessary to equip a special fuel storage, for example, to install a tank. In addition, to this tank it is necessary to provide access roads for fuel trucks.

Another significant drawback is the characteristic smell of fuel, and therefore for the normal operation of this equipment requires a specially equipped boiler room.

Important: Fuel oil units are currently practically not produced due to lack of demand. The limited demand, in turn, is due to the permanent increase in prices for petroleum products.

- Solid fuel boilers (Efficiency up to 80%) - designed for burning firewood, coal, pellets (fuel pellets) and pressed briquette.

The main advantage of these units is "omnivorous", since, in addition to the listed types of fuel, they can burn various household wastes.

Modern solid fuel devices are no more expensive than gas analogues. But, deciding to purchase a wood boiler, it is necessary to take into account the fact that this equipment does not imply the possibility of automation. Again, from time to time you will have to go to the boiler room in order to throw firewood with your own hands and clean the ash pan.

Important: Buying a solid fuel boiler, do not forget to equip a woodpile or storage for coal.

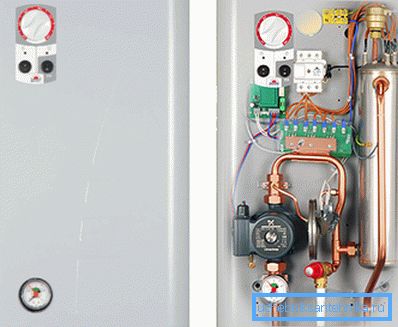

- Units running on electricity, mainly used in country houses used for seasonal living. The fact is that the continuous operation of such equipment is unprofitable, since the power consumption is at least 2 kW / hour.

The operation of this equipment is characterized by ease of convenience and safety, since most of the boilers are automated.

Important: When deciding on the purchase of an electric boiler, make sure that the wiring in the house can withstand the workload of the heating equipment.

Choosing a gas boiler

Now we know in accordance with what criteria the choice of the heating boiler is made. Moreover, we know what equipment is presented to the market today, and what to choose from. It remains to consider the type of heating equipment that will provide low-cost operation with optimum heating quality of enclosed spaces.

Gas heating boiler is powered by natural gas. If for some reason access to natural gas is limited, certain models may use liquefied gas as fuel.

Currently, more than half of all heating equipment sold in the Russian Federation is represented by gas boilers.

In accordance with the installation features, all these units can be divided into floor and wall modifications:

- Devices with a floor layout are powerful and high-performance units with increased sizes and, as a result, with a considerable weight. Until now, most of the domestic installations are made in the floor version. Given the considerable size and location features, for the installation and subsequent operation of such devices will require a special boiler room.

- Devices with a wall location are, as a rule, household appliances of medium or low power (no more than 30 kW). Small dimensions convenient configuration excellent appearance, all this allows not only to perform the installation on the wall, but also to do without the use of a special room. As a result, wall units can be installed in any room with an area of at least 6 m ?.

Important: Both categories of heating equipment imply the preparation and coordination of the project, according to which the installation work will be carried out. Unauthorized installation without the preparation and coordination of project documentation may result in an administrative penalty of a fine!

Gas floor boilers, in turn, are divided into the following groups:

- Modifications equipped with atmospheric burners are characterized by simplicity of design, low cost and almost complete absence of noise during operation.

- Modifications with inflatable burners are a versatile solution that allows flushing using both natural and liquefied gas. In addition, these modifications from previous devices are distinguished by greater efficiency and higher price.

Devices with the possibility of wall mounting, in turn, are subdivided into modifications with forced discharge of exhaust gases and natural fatigue.

In the first case, the devices used a closed combustion chamber, and in the second case - open. This parameter does not directly affect the degree of productivity, but if natural-fired boilers are used, it is necessary to take care of the construction of a sufficiently high, reliable and safe chimney.

In units with forced duct, the chimney, equipped with an integrated axial fan, comes in original configuration. Thus, units with forced ventilation and a closed combustion chamber are simpler, safer and more convenient both during installation and in the course of daily operation.

Both floor and wall boilers running on natural gas can be either single-circuit or dual-circuit.

- Single-circuit modifications are intended only for heating the coolant in the pipeline and radiators.

- Dual-circuit modifications heat the coolant and heat the water used to meet domestic needs.

Dual-circuit modifications can be equipped with two heat exchangers, then during the supply of hot water to the water supply system, the heat transfer medium in the heating system does not cease to warm up.

Also on the market there are more affordable in terms of cost modifications and with one heat exchanger. In this case, while hot water is being supplied to the plumbing, the heating is suspended. Heating starts again when you stop using hot water in the water supply.

Such a system is implemented in some models of the IMMERGAS brand of the middle price segment. According to users, limited functionality in the cold season does not cause inconvenience, despite the fact that the price of such equipment is on average 25% lower than the cost of full-fledged dual-circuit counterparts with two heat exchangers.

Important: To save energy without sacrificing the quality of heating, so-called condensing gas boilers allow (efficiency up to 107%). This equipment on the market appeared relatively recently, and therefore the cost of the proposals so far is high.

If gas is not available, choose electricity.

As already mentioned, natural gas is a cheap fuel, but sometimes it is impossible to connect to the mainline. If a country house or cottage is used from time to time, a good alternative to gas will be electricity.

Yes, electricity is expensive, but only if you drown around the clock and throughout the season. If you come to a country house only on weekends or on holidays occasionally, heating with electricity will not break through a significant gap in your budget.

Therefore, the choice of heating boiler power in this case is not fundamental, it is much more important to decide on the features of work and the functionality of the equipment.

Electric boilers on the market are represented by the following modifications:

- Rheostat units (indirect action) - a rheostat cartridge (TEH) is used as a heating element in them. The heater (one or more) is located in the heat exchanger and is responsible for heating the water to certain temperature parameters, after which the thermal switch is activated and the coolant cools until the relay works again and starts the system.

Important: Rheostat installations are characterized by large dimensions than electrode counterparts, but at the same time demonstrate less exactingness to the quality of heated water.

- Electrode units (direct action) are represented by steam boilers and water heaters. In these installations, electric current passes between the electrodes directly through the water, releasing heat.

Conclusion

So, we examined what the manual is and what are the features of operating current heating equipment today. It remains to determine what to choose.

It would be incorrect to give specific advice on the need to purchase this or that equipment, since the choice of a boiler for heating a house should be carried out in accordance with the features of the construction project and in accordance with the preferences of the buyer.

Are there any questions that need clarification? In this case, you will find more useful information by watching the video in this article.