How to choose a pump for the heating system: a simplified

Selection of a pump for a heating system is an important design stage, as a result of which the unit most suitable for the characteristics should be found. We will talk about the main criteria and methods of such selection, and analyze how to choose a pump for heating.

Calculation of parameters

Main characteristics

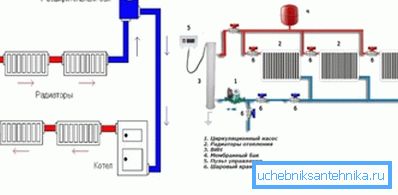

Heating schemes are different, and the main difference is the method of moving coolant from the boiler to the radiators.

There are two main ways:

- Natural circulation. Occurs due to gravity due to differences in the density of hot and cold water. Since the efficiency of heating depends on the flow of hot water, the speed of natural circulation in the heating system of the house is often not enough;

- Forced circulation. It is carried out by installing a special unit into the pipeline, which pumps the coolant at the required speed and pressure. Most modern heating schemes are based on the principle of forced circulation.

Note! Do not confuse the centralized flow scheme with natural circulation: the coolant in urban apartments comes under considerable pressure, which is injected with special equipment.

In order for the scheme to work normally, the instruction requires the calculation of all its parameters, on the basis of which the sections of the pipeline, the radiator power, the boiler capacity and power, the heating circulating pump capacity will be selected. One of these parameters is the hydraulic characteristic:

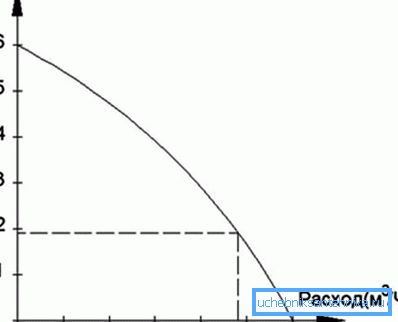

On the graph, we see that the resistance is directly dependent on the coolant flow, that is, the faster the water moves along the contour, the more resistance it experiences. Accordingly, the pressure rises.

Now consider the pressure characteristics of the circulation device:

In this graph, we see the dependence of the pressure loss on the flow rate of the pump. Here we see an inverse relationship, that is, when the engine is turned off, the losses are maximum, and as its power increases, the losses fall.

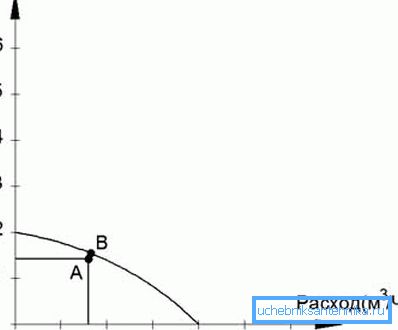

If we combine these two graphs, we get the following picture:

Note! The working point allows us to determine what resistance will be in the pipes at the maximum flow (flow) of the coolant. This means that our apparatus must have sufficient capacity to provide the required flow, but at the same time its capacity must be sufficient to cope with the corresponding hydraulic resistance.

Performance calculation

Since it will be difficult to build a graph of the hydraulic characteristics of the heating circuit with our own hands, we will use the calculation according to a simplified scheme. So, we need to determine the maximum flow rate (capacity) and hydraulic resistance. Let's start with performance.

The heat energy consumed by the heating circuit is expressed by the following dependence:

The formula uses the following values:

- W is the thermal energy required for heating our premises in watts (thermal power of the circuit);

- C is the heat capacity of the coolant, W / liter * ° C;

- Q - coolant flow rate, m3 / hour;

- t1 and t2 are the temperatures of the supplied and withdrawn coolant, respectively.

Selection of the pump for heating is on performance. The performance of the device must correspond to the maximum flow rate of the coolant, so we transform our formula for finding the flow:

Q = W / C * (t1 - t2)

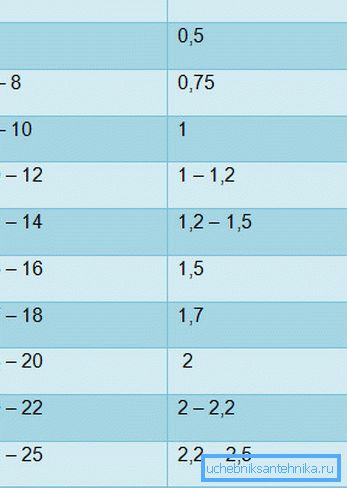

The amount of energy W can be found using the table:

The heat capacity of water is assumed to be 1.163 W / liter * ° C, the temperature difference between the supply and return flow is 20 ° C (according to the SNiP). From here we get:

Q = W / 1.163 * 20 = 0.043 * W

Note! That is, if we need to determine the coolant flow rate for a room with heating heat of 10 kW, then we will need to multiply 10,000 by 0.043, and we will get 430 liters per hour.

Calculation of hydraulic resistance

Professional and accurate calculation of the hydraulic resistance of the heating circuit is a very difficult task, requiring special knowledge and skills. We will use a simplified method, according to which the pressure of the circulation pump will be equal to:

H = N * k, where:

- H is the height of the water column in meters;

- N - the number of floors in the building, including basements;

- k is a coefficient equal to the average hydraulic loss per one floor of a building or structure. SNiP take this coefficient equal to 0.7 - 1.1 m for two-pipe schemes and 1.16 - 1.85 m for collector-beam supply organization schemes.

Note! Thus, it turns out that if we have a two-story house with a basement, equipped with a two-pipe heating pipeline, then the engine must provide a pressure equal to 3 * 1.1 = 3.3 meters.

Pump selection

So, we have two quantities - resistance and performance. Let's return to our schedule with the pressure head and account characteristic.

We postpone the resistance value on the Y axis, and the flow rate value - on the X axis. Then select the unit, the graph of the pressure-flow dependence of which is near this point:

Note! As a rule, the graph shows three lines for different modes of operation of the motor. It is best to be guided by the second speed, and the operating point should be located in the middle third of the diagram, since it corresponds to the highest efficiency.

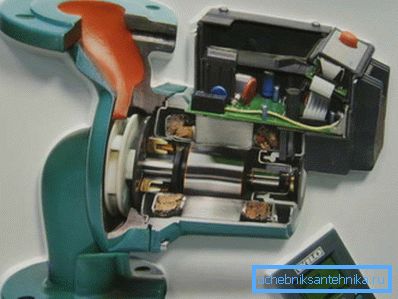

Of course, it is necessary to select a device designed for high ambient temperatures (95 - 110 ° C), and also to know the diameter of the pipe into which the device will be embedded. The price of the device will depend on the manufacturer and quality.

Conclusion

The correct choice of the circulation pump for the heating circuit is made on the basis of calculations. If the material presented seems too complicated to you, watch the video in the article.