How to choose bimetallic heating radiators: an overview of

In the overwhelming majority of cases, in designing new and modernizing existing space heating systems, not outdated cast iron heating elements are used, but new ones made of steel and aluminum. They are more beautiful, strong enough and have an excellent heat transfer coefficient. However, it is very important to know how to choose a bimetallic heating radiator in order not to be disappointed in the purchase. The instructions below will help you with this.

Choice of heat sources

Specifications

It's no secret that the most efficient and inexpensive way to heat a room is to install heating radiators in which coolant circulates, heated by a boiler, circulates. Considering that the main elements of the system are located directly in the room, and, as a rule, are not hidden by any decorative panels, when choosing them, the determining factors are not only heat emission, weight and price, but also an aesthetic appearance.

Let us dwell in more detail on the parameters that must be taken into account before choosing heating radiators - bimetallic, cast iron, aluminum or any other.

Note! Particular attention in this article is paid to the first name of the first type of heating panels, since, looking ahead, it should be noted that they are today the undisputed leader among similar products. They harmoniously combine the advantages of steel and aluminum products, and most of their drawbacks are absent.

The main advantages of bimetallic batteries are as follows:

- Increased strength. Any equipment used to install the heating network must withstand the internal pressure generated by the circulating coolant. Due to its special design, aluminum models with a steel core can withstand from 20 to 35 atmospheres. Despite the fact that the real pressure of the fluid in the radiators rarely exceeds 15 atmospheres, the high strength of the steel frame allows excellent resistance to water hammering. And this is very important when connecting to the networks of centralized heating.

- Long service life. The increased strength of steel, while observing the rules of installation and operation, contributes to the fact that the described radiators can last for 20 years or more. In addition, only the cores come into contact with water, which is the cause of corrosion, which also prolongs the time of trouble-free operation of the heating panels.

- Small diameter of the internal pipeline. Steel pipes that run inside the aluminum heat exchanger have a small cross section. This allows you to design and manufacture individual heating systems with less water circulating through them, which, in turn, directly affects the economy.

- Slight inertia. Thanks to the use of aluminum heat exchangers, the gap that runs between turning on the boiler and heating the radiator to the operating temperature is minimized. In addition, such systems very accurately respond to commands from thermostats, which makes it possible to create the most comfortable conditions in the room.

- High level of heat transfer. By purchasing bimetallic models of radiators, you can be sure that almost all the heat energy of the coolant will be used to heat the room. Not a single watt of energy is wasted. The batteries in question have been specially developed for use in high pressure heating circuits filled with low quality coolant. They perfectly withstand not only hydraulic, but also mechanical effects, including shock.

It does not matter what indicator of acidity of the water flowing in the heating system, as it is not in contact with aluminum. The main thing is that the pipeline and the radiator should be completely filled with water, in no case should it be allowed to air.

The lack of aluminum radiators with steel cores is one - the high cost. They are almost a quarter more expensive than following them in terms of the effectiveness of aluminum batteries. However, according to the majority of experienced professionals involved in the installation of climate networks, this difference fully pays off during operation.

Features of specific models

Bimetallic heating radiators, as you can see, are best suited for designing your own heating system. Now it is advisable to dwell on such an issue as the choice of a particular device modification among the models represented on the construction market.

Outwardly, it is almost impossible to distinguish a fully aluminum panel from a bimetallic panel. They differ only in weight: the latter is almost twice as heavy.

In addition, the products themselves are of two types:

- Batteries, where the base for the aluminum heat exchanger is a steel frame. In this case, the contact of the coolant with non-ferrous metal is completely excluded, which has a positive effect on the service life of the equipment.

- Radiators, whose design is only strengthened by the use of steel pipes. In this case, the workmanship comes to the fore. A slight shift of steel elements due to poor fixation and temperature expansions can completely eliminate the coolant access to the lower collector, which greatly reduces the efficiency of the panel.

Tip! Preference is desirable to give the first model. However, you need to know that their weight, as well as cost, is greater than that of the second variety. In addition, when heated, the core may produce extraneous sounds (during the thermal expansion of the steel frame).

Radiators are sold with a set of sections from which you can independently make a battery of the necessary power. Packed in packs of 10 pieces each. One section, depending on the model and manufacturer, is designed to heat about 2 square meters. square meters (the power calculation method is described in more detail in the next section).

In addition, the special design of the aluminum heat exchanger allows this device to organically combine the properties of both a classic radiator and a convector, which organizes the circulation of air flow through the room.

To protect against adverse environmental factors, the surface of the batteries is covered with a special powder coloring composition, which has a high resistance to mechanical stress. Thanks to him, the radiator is easy to clean from dust and wash with ordinary household detergents.

In order to avoid leaks and breakdowns of installed heating equipment, the quality of bimetallic heating radiators is controlled at all stages of production: from the acquisition of the necessary raw materials to the storage and delivery to retail outlets.

Power calculation

Before installing the heating system and buying batteries, it is necessary to know exactly how many sections these products should be installed in each of the rooms. This parameter can be calculated. To do this, you should know the area of each room (not the entire object as a whole), as well as the power of one section of the radiator you purchase.

So, the formula for calculating:

A = S * 100 / P, where

And - the number of sections in the battery;

S is the area of the room where the radiator will be mounted;

R - power section of the radiator.

Installation

Before installing aluminum batteries with a steel frame, it is advisable to familiarize yourself with the recommendations specified in the accompanying documents (instructions). It is desirable that the connection is performed by an experienced specialist who has the appropriate skills, confirmed by certificates or certificates.

The very same procedure for installing radiators is as follows:

- Before connecting to the heating network, the batteries and piping must be flushed with a pipe cleaner. It is forbidden to use solutions containing alkali, as they may cause damage to the steel cores of products. In addition, the outlet nozzles can not be cleaned with abrasives, otherwise in these places there may be leakage of coolant.

- In a specially provided place on the radiator you need to install a valve (Mayevsky's crane), working automatically or unscrewing manually. This will help remove the airlock that forms when the system is filled with coolant.

- In order to avoid contamination of the internal space of the battery, strainers can be placed at the inlets of the batteries to trap particulate matter.

- After that, the space for the brackets is laid out, which will hold the battery, the holes for the dowels or anchor bolts are drilled and the mounting elements are installed.

- The radiator is hung. It is necessary to “fit” the horizontal elements of the panel (located between the vertical sections) on the places specially provided for in the brackets.

- After that, the heating panel is joined to the pipelines. Do not forget to install shut-off valves, which will allow not only to regulate the temperature in the room, but also to partially block the heating system when it is necessary to repair or replace the battery.

- The final stage is to bleed air with a pre-installed valve.

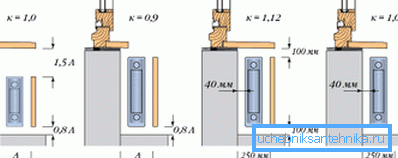

Remember that during installation it is necessary to observe the distance recommended by the manufacturer between the bimetallic radiator of heating and the wall, floor, window sill and other structural elements:

- between the wall and the surface of the aluminum heat exchanger - not less than 3 cm;

- between the floor and the bottom edge of the battery - about 10 cm;

- between the sill and the upper edge of the radiator - not less than 10 cm.

If the windows are equipped with wide window sills, you can provide them with special overflow ventilation grilles through which heated air will rise up, eliminating window fogging.

Tip! For a more efficient heating of the room and the rational distribution of thermal energy should not close the battery with decorative panels, furniture, curtains and so on.

Conclusion

Aluminum steel-framed heating panels are one of the best ways to provide warmth to living spaces. However, for their work requires the installation of the boiler and piping. If necessary, heating a small country house or other premises not intended for permanent residence of people, it is advisable to use other schemes. More details about them can be found in the video offered to your attention.