How to equip a brick chimney for a solid fuel boiler

If you decide to build a house where a solid fuel boiler is provided for the heating system, it is necessary to determine the place to install its chimney. When developing a project and during installation of the latter, it is necessary to take into account the relationship between heat generation and heat loss. Brick chimney for solid fuel boiler should be installed in compliance with all measures of cleanliness of the air in the room and fire safety.

Our task today is to tell about the installation rules for this type of chimney, its laying, as well as materials and tools necessary for work.

General information on parts of the smoke system

We begin with a solid fuel boiler, which is a heating device of the classical type. It can be found in almost every private house, where there is no gas supply line. It is convenient because in the fuel chamber it is possible to burn both coal, and firewood, and peat.

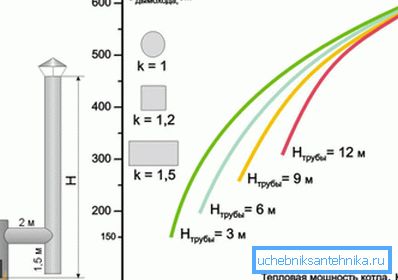

To get the maximum heat transfer from the equipment, it is necessary to correctly calculate and manufacture the chimney, in our case of bricks.

It must meet the following requirements:

- not to present obstacles to the supply of air necessary for the efficient operation of the heating device;

- to create thrust arising due to the difference in temperature and pressure, sufficient for removal of combustion products.

Smoke pipes for solid fuel boilers can be made from:

- bricks;

- certain brands;

- ceramics.

The classic option is a brick chimney, which you can do with your own hands.

Installation rules

Often, homeowners are in a hurry themselves or negligent workers who come across them who believe that they may slightly deviate from generally accepted requirements. As a result, accidents occur, which, alas, can be fatal.

To prevent this from happening, we strongly recommend that you follow the recommendations below:

| Fire safety |

|

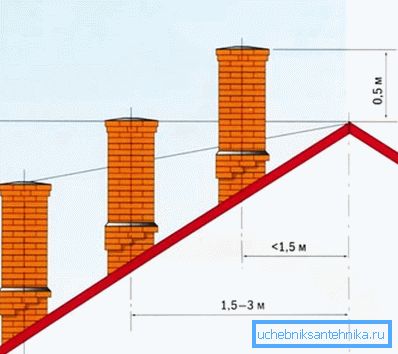

| Height |

|

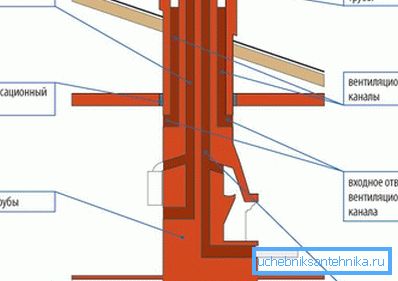

| Condensate drain | The instruction requires that this condition be met for any type of chimney. It is necessary to provide places for condensate discharge, for maintenance, and also for cleaning from soot and possible debris. Otherwise, the thrust will gradually decrease to such an extent that the smoke will flow into the room. |

| Section | The area of internal section along the entire length of the pipe should be the same. Otherwise it will greatly worsen the passage of combustion products. |

| Additionally |

|

Why do many people prefer brick chimney? It depends on the fact that the exhaust gases can heat up to a temperature of 600? С, so the design must be resistant to it.

The brick corresponds to this parameter as much as possible, although the price of chimney masonry works, and the material itself is not so cheap today. But after installation, you can not worry about it for a long time.

Tip: apply refractory mortar to the internal walls of the brick chimney at the time of its construction, and then you can protect it from the harmful effects of aggressive acid sludge and condensate.

How is brick chimney laying

The laying of a smoke brick pipe cannot be called a simple occupation; this will require certain knowledge and skills in order to understand technological processes.

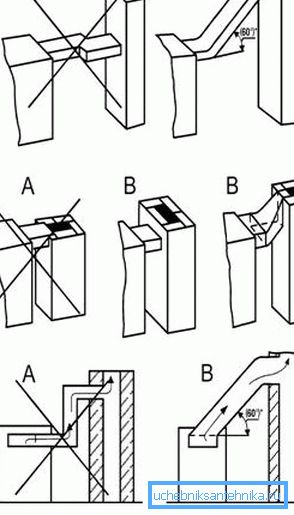

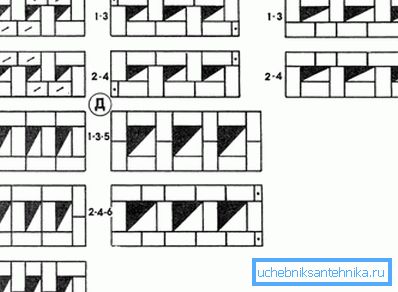

- A simple option is a chimney device, when a brick channel must be made inside the walls. In this case, an unencumbered shaft with a cross section of brick (250 mm) is left. The cross section of the chimney can be calculated according to the following standards: 1 kW = 0.08 m2. Accordingly, if the power of a solid fuel boiler is 10 kW, the cross section of the smoke brick pipe must be at least 0.8 m2 or about 300x300 mm.

- When creating a separate chimney should be very careful and responsible in the work. When laying masonry, pay special attention to angles that should be perfectly flat. Also ensure that there are no protuberances on the walls.

Tip: a chimney not adjacent to the wall must be made strictly in the vertical plane.

- The chimney adjacent to the wall for reliability should be additionally fixed with the help of anchors that need to be positioned after about 4-5 rows. In this case, you should also think over where the technological and inspection openings will be located.

Tip: be sure to make the bottom of the chimney hatch through which you can easily remove accumulated soot.

- In order to increase the efficiency of the structure, the inner surface of the pipe must be even and smooth, then the smoke can flow out freely.

- One of the most common options used for the interior of the canal, plastering "under the mitten." Thanks to the use of this method, its section in shape will be as close to the circle as possible. Although some experts consider this method of interior decoration impractical, as after some time the plaster will begin to peel off and clog the flue duct.

Tip: lining the outer part of the chimney with bricks or sheathed roofing material to protect it from weathering.

What you need to prepare for work

The simplicity of the construction lies in the fact that for its construction it is enough to have a brick and a mortar for laying it on hand.

However, you should not treat the work haughtily, it should be done according to all the rules and very carefully, otherwise your heating system will simply not work properly and the pipe will have to be disassembled and relocated, which is a big expense.

- When choosing a brick, make sure that it is well burned. The color of the material should be uniform on all sides. The edges are even and clear, which will make it possible to make seams of small thickness.

- Prepare the solution in a special way and include sand, clay, cement and water in its composition. Especially important is the selection of sand, which should be fine, which will make the solution more plastic.

- Prepare from the tools:

- trowel;

- hammer pick;

- roulette wheel;

- building level and plummet;

- spade for the solution;

- construction line.

Laying features

- Work start directly from the heater.

- It is possible to connect the boiler with the brick chimney with a pipe of the appropriate size and diameter.

- Laying sure to lead with ligation between the rows. In principle, it resembles the construction of partitions or walls, although there are some features that need to be considered:

- Be sure to check each row level in the vertical and horizontal planes;

- clay must be mixed in the solution;

- the thickness of the seam should be about 5-10 mm. We do not recommend to do more, because due to a periodic temperature difference, the solution will begin to crumble, and this will inevitably lead to the destruction of the chimney;

- Sealing of all seams must be of high quality, through holes are unacceptable;

- when laying should use only whole bricks, reducing the maximum use of the halves.

Conclusion

The solid fuel boiler needs a properly installed chimney. In this case, it will be able to work as efficiently as possible - burning all the fuel and transferring the required thermal energy to the coolant.

Often, homeowners stop on a brick chimney, although its laying requires a lot of time and effort, but it completely copes with its task for a long time. The video in the article will help you find additional information on this topic.