How to install a two-pipe heating system

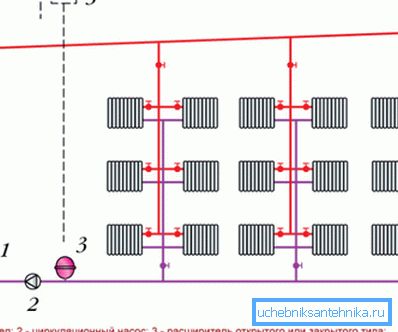

The most commonly used heating system is water. With its help, more than 67% of all facilities in our country are heated. It has several varieties, among which the most popular is the two-pipe. Today we set ourselves the task of telling about what constitutes a two-pipe heating system with natural circulation and with mechanical one in more detail so that you get as much knowledge about it as possible.

What is the principle of operation

In this case, there will be no surprises, the system is a closed loop through which the heated coolant circulates from the heater to the radiators. The same principle is observed in all other structures where water is used for heating.

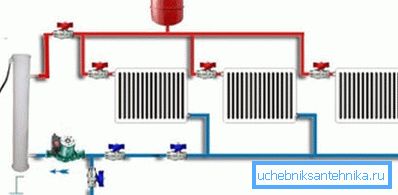

The only difference is the use of two pipeline branches simultaneously:

- the first one transports and distributes hot coolant;

- the second one removes the cooled liquid from the radiators and returns it to the boiler.

Advantage

An alternative option is a cheaper and simple one-pipe construction, but, due to the obvious advantages of the two-pipe, it is losing its popularity. Consider them in more detail:

| Temperature |

|

| Pressure | Pressure losses are reduced, this allows you to install a less powerful and economically viable circulation pump. |

| Installation | The instruction permits installation of the system in a one-story or multi-storey building, as well as in apartment buildings. |

| Repairs | Shut-off valves on the supply pipelines allows for the repair of parts and elements of the system without stopping it. |

Of the shortcomings, a double pipeline length is usually noted, which increases financial expenditure compared to the one-pipe option. Although in this case it cannot be considered a negative property, since the pipes are used with a small diameter, the dimensions of fasteners, valves, connections and fittings are also small.

In fact, the total costs only slightly exceed the expenditure on a one-pipe heating system. At the same time, you will get much more benefits.

Kinds

Heating systems are generally divided into open and closed.

The main criterion for this separation is the type of expansion tank used in the design.

- In the open version, it is placed on the uppermost part of the circuit, from where the coolant can evaporate freely. In this case, the internal pressure of the system will be relatively low.

- The closed standard twin-tube version is equipped with a membrane-type expansion tank, allowing fluid to circulate around the circuit under forced pressure. Since its evaporation is absent, it allows using more practical solutions, in the form of glycols, as a coolant in addition to water. Closed systems are considered the most secure and environmentally friendly.

Depending on the location of the pipelines that connect all the elements of the structure, we can distinguish:

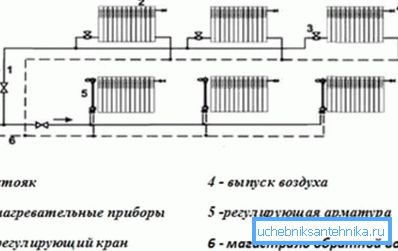

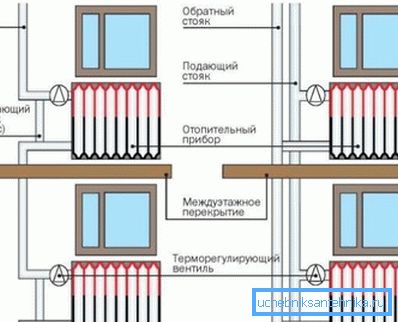

- Vertical two-pipe heating system when the batteries are connected to a vertical riser. Apply it in multi-storey buildings, giving the opportunity to attach to it each floor separately. The main advantage of the design is the absence of air plugs when using it. The price of arrangement will be higher than other options.

- Horizontal 2-pipe heating system is usually used in one-story buildings with a large area. Connection of heaters is carried out to a horizontal pipeline. The accumulated air is discharged using the Mayevsky crane.

Tip: in this case, lay the risers better on the landing or in the corridor.

Layout

Apply two basic designs:

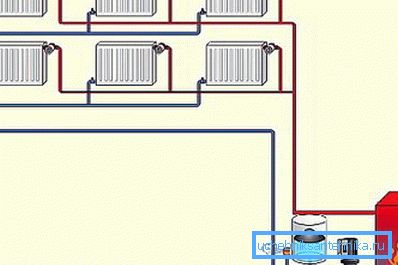

- The bottom, when the pipeline coming from the boiler is laid in the lower part of the building, for example, in an underground space, floor or basement. The reverse position is even lower, and to obtain a normal circulation of the coolant, the boiler is placed lower, so that all radiators are placed above it.

Tip: be sure to turn on the air line in the circuit, setting it on top. With its help, excess air will be removed from the network.

- The upper one, when the distributor line passes through the top of the structure, and the expansion tank is mounted at the highest point of the circuit. Usually pass the pipeline through the insulated attic, which is unacceptable for buildings with a flat roof.

Tip: two wiring options can be used for both horizontal and vertical heating systems.

Hydraulic calculation

It must be done before the start of work on the installation of heating structures, since for each structure it will be individual. The hydraulic calculation of a horizontal two-pipe heating system, as well as a vertical one, is usually carried out according to a preliminary “draft” scheme, which includes all the elements.

During the calculations, the most loaded ring of the pipeline is identified, which should be taken as the object being calculated and divided into conditional sections.

As a result, the homeowner will receive:

- the value of the possible pressure loss in the circuit;

- the most optimal diameter of pipelines;

- the area of radiators necessary for heating, from which it is possible to obtain a number of heating devices

Hydraulic calculation of a two-pipe horizontal heating system is carried out using several techniques.

Below we tell about the most common:

- Calculations are carried out taking into account the characteristics of resistance and conductivity values. Thanks to this, it is possible to obtain real data on the temperature of each element of the heating circuit and the exact flow of water.

- Calculations are carried out on the specific pressure loss. The result is a clear physical picture of the process, which demonstrates the actual distribution of resistance in the pipeline.

Hydraulic calculation of the two-pipe heating system finally allows you to know the exact parameters of temperature, as well as coolant flow in any part of the circuit. This will be the basis for organizing a building heating plan.

Installation

Installation of a 2-pipe heating system begins after the calculations, drawing up an accurate circuit diagram and the acquisition of the necessary equipment.

Below will be told about the order of its implementation:

- Install a heating boiler. The best option is a small separate room, where ventilation is properly equipped, which will remove the combustion products. We recommend to revet the floor and walls with specially designed refractory materials. Position the boiler away from the walls, with a convenient approach to maintenance.

- Secure the circulation pump to the pipeline and distribution manifold, if provided for by the plan.

- Run the pipeline from the boiler to the radiators. In the walls, make small holes, which are then sealed with cement mortar. Connections depend on the composition of the pipe material.

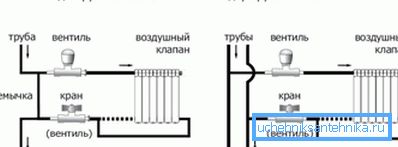

- Connect the radiators. The heating circuit of each battery should consist of two pipes - the top one with the hot one, the bottom one with the cooled heat carrier. Install the radiators with your own hands under the windows using special brackets.

The optimal distance from:

- radiators - 100 mm;

- floor - about 120 mm;

- walls - 20-50 mm.

Install control and gate fittings at the inlet and outlet. Thermal sensors will help you easily set a comfortable temperature in the room.

- Perform a system check after all work has been completed.

Conclusion

From this article, you learned what a horizontal two-pipe heating system, as well as vertical, are widely used today to create a comfortable temperature in housing and industrial buildings. Thanks to its undeniable advantages, it has become very attractive to consumers.

More than 2/3 of households and enterprises chose it for the arrangement of heating. When planning it, it is necessary to carry out a competent hydraulic calculation.

The video in the article will help you find additional information on this topic.