How to install the pump in a forced-type heating system

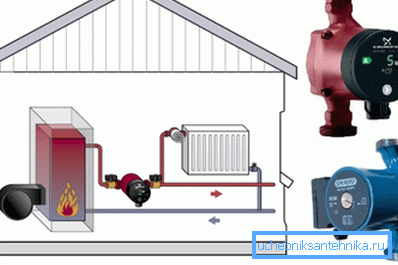

In the forced heating system, the pump allows the coolant to circulate through pipelines, delivering it with minimal losses to the most extreme radiator. This allows you to reduce the diameters of pipes, as well as hide them in a wall or floor, thereby ennoble the interior. Our task today is to tell where and how to install the circulating pump correctly so that it evenly distributes the coolant through the system.

Forced circulation

In contrast to the natural, where the coolant moves due to physical reasons - the hot liquid is replaced by cold, in this case, everything depends on the movement of the impeller.

Tip: if when you turn on the pump, most of the circuit remains cold, and air plugs are not detected, it makes no sense to increase its capacity. The best solution is to replace it, since the device can no longer create the necessary fluid pressure.

Advantage:

- in the system is aligned temperature;

- the appearance of air plugs preventing the free movement of the coolant is eliminated;

- significantly increases the length of the heating circuit.

How to choose a circulation pump

For an ordinary apartment, it makes no sense to acquire a powerful device, as the length of the pipeline rarely exceeds 25m. However, its price depends on the manufacturer and the materials from which it was made.

When selecting a circulation unit, you need to know only a few parameters, among which the velocity of the coolant is not the most important. On the contrary, it should move at a smooth, relatively slow pace. In addition, the larger the device, the more noise it will make, which is not very pleasant.

Tip: for a large and complex home, the best solution would be to seek the help of professionals who will do all the calculations in a short time.

For an ordinary country house, you can use the following table:

| Coolant flow rate (l) | Pipeline Diameter () |

| 5.7 | ? |

| 15 | ? |

| thirty | one |

| 53 | one ? |

| 83 | one ? |

| 170 | 2 |

According to the table, there is a direct dependence of the distribution of the coolant in the pipeline from its diameter. It should also be noted that the standard velocity of the fluid in the heating system is 1.5 m / s.

You should also consider that the passage of coolant in one minute is equal to the power of the boiler. For example, if it is 25 kW for a heating unit, it means that 25 liters should pass through the liquid in one minute.

When choosing a pump, one should not forget that its power is proportional to the length of the pipeline. For example, for a contour 100 m long, a pressure of 6 m is needed.

Types of devices

Currently, 2 types of pumps are used for circulating coolant:

- "Wet" - the working part is in contact with the coolant, therefore, they are used in residential premises, as it is almost silent;

- “Dry” - the rotor has no contact with the coolant, devices are usually used in non-residential premises, as they have increased noise in the work.

Make both versions of the device from materials that are not susceptible to corrosion:

- body - brass or bronze;

- other parts are plastic, ceramic or stainless steel.

In “wet” devices, there is practically no jamming of the device, since during its movement the coolant lubricates its parts.

Preparation for installation

Below is a brief guide with recommendations:

- We recommend to purchase a product with detachable threads, then you can make your work as easy as possible. Otherwise, you will have to pick up adapters yourself.

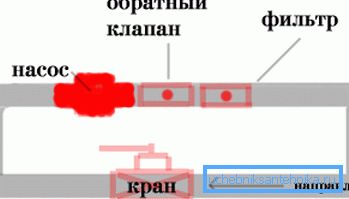

- Immediately buy a filter for coarse pipe, non-return valve, which will make the work of a high-pressure pump.

- You will need another bypass and valves of the required diameter.

- Don't forget the keys for the nuts.

Choose a place to tie in

- It is desirable that there is free access to the device for its periodic maintenance.

- There should be access to electricity nearby. Otherwise, you will have to pull the power cable to the installation point of the device.

- Previously recommended to install a pump on the return line, today their design allows you to do it anywhere.

- To increase the pressure at the suction point, it is better to install the device in the supply pipe. Especially well, if there is located near the place of entry of the expansion tank heating system. In this case, a high temperature is guaranteed.

If the device is installed in a heating system with a membrane-type tank, it is better to bypass it with the tank. We recommend it as close as possible to the place of installation of the expansion tank.

Tip: if installing a bypass with a pump on the return pipe will make access to the pump more difficult, it is possible to fix the supply, but a vertical check valve must be inserted vertically.

Installation Rules:

- Secure the ball valves to the sides of the device. This will allow you to quickly dismantle it without draining the coolant from the system.

- Directly in front of the pump should be cut in the filter, which protects the equipment from dirt and particles that may be in the coolant

- At the top of the bypass it is necessary to install an automatic or manual-type breather valve. So you can quickly get rid of the air in the system, accumulated there for various reasons.

- Installation of the pump should be carried out in the direction of the coolant, on the device there is a corresponding arrow.

- Threaded connections should be coated with sealant, wrapped with a fum tape, and also installed gaskets between the mating parts so that there are no leaks in the system.

Tip: the socket for the pump must be grounded to ensure the safety of its use.

Installation process

- Drain the coolant from the system, if the installation will be made to the existing network. For a new pump, it is better to use a new coolant; at the same time, you can also flush pipelines and radiators from possible contamination.

- Install valves and pumps as specified in the preceding rules..

- At the end of the installation cycle, fill the system with fresh coolant..

- Before starting the pump, unscrew the central screw on the casing with a screwdriver and discharge the excess air from the device; after the appearance of water, tighten it tightly.

Conclusion

Installing a circulation pump in the heating system allows you to save fuel, to produce rapid heating of the coolant, making the room temperature comfortable for a short period.

The work is simple, easily done by hand, but requires adherence to certain rules. You will only have to choose the right device to provide the house with heat. The video in the article will help you find additional information on this topic.