How to make a solid fuel boiler yourself: guide to action

If you want to know how to do heating boilers for solid fuel with your own hands, then you went to the right address and, although we will not consider all possible options, you will understand the essence of such installation. Of course, we cannot guarantee you an unusually high efficiency, but with proper adjustment of the oxygen supply dampers and adjustment of the thrust, you can definitely get 65% for the heating circuit.

Materials, assemblies and assembly of this device will be presented step by step to you below, and in addition, you can watch a thematic video clip.

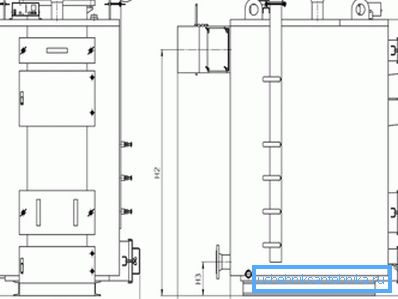

Solid fuel boiler

Note. This equipment has much in common with the familiar for most readers stove, but at the same time, the differences, on the principle of which it gives off heat, make it a completely different device.

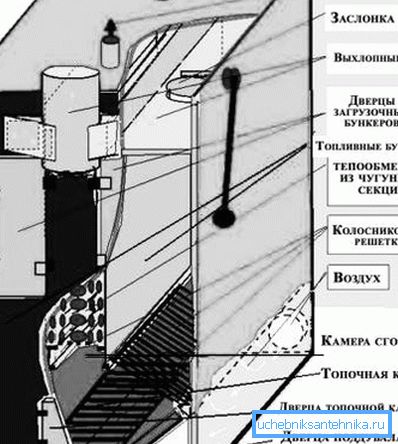

The main components of the structure

- The list of main elements includes the fuel chamber, where, in fact, solid fuel burns.. This chamber is necessarily equipped with a grate, through which oxygen is supplied that is necessary for the combustion process.

- We also need either a tubular heat exchanger or another water tank made of heat-resistant steel or cast iron. - This element is often called the water jacket.

- A throttle valve system is needed to adjust the flow of fresh air and close the traction channels after attenuation. - in a conventional oven, these functions are performed by the door of the blower and the gate (view).

- Well, and, of course, the chimney, which is necessary for the removal of combustion products (smoke) and to create thrust in the fuel compartment.

- All these knots consist in the steel case.

Note. In order to ensure uniform heating of the room even during fuel attenuation, the instruction recommends installing a heat accumulator above the boiler. It is a steel design capacity, where heat is concentrated during the activity of the unit.

In addition, a stainless steel tank for hot water is equipped above the heat accumulator. This node is not mandatory, but by doing so, you provide a second circuit, that is, the boiler is double-circuit.

Materials and tools

- In order to assemble a heating boiler on solid fuel with our own hands, we will need certain tools and, of course, materials, among which, first of all, sheet steel can be called at least 5 mm thick.

- We also need a metal corner, water steel pipes (preferably seamless) and an iron grate.

- The firebox and ashpit will need doors, as well as throttle furnace flaps, stainless steel sheet for a heat accumulator and a tank for hot water, river (quarry) sand (sifted).

- From the tools you, of course, can not do without gas, and preferably electric welding, which can be connected at home.

- At the grinder, that is, grinders with discs for cutting metal.

- Also, you will need an electric drill with a full set of drills, pliers, construction level, steel measuring corner and metric tape measure with a ruler.

Assembly

The most loaded place is technically represented by the combustion chamber, where the air temperature during burning of coal can reach 1000? C. But this is the basis of the whole structure.

Therefore, if you cannot find a sheet of heat-resistant steel anywhere, then it is best for you to make this chamber double. That is, you make the bottom, top, back and side walls in two layers - first you assemble the cube, and then sheathe it with another layer, trying to fit all the dimensions as precisely as possible.

For the convenience of such work, it is best to use a metal workbench or just any table on which you can cut and cook sheets of metal.

If you look closely at the drawing, then you will see there the designations of the parameters, which are given in millimeters. You transfer them to a steel sheet with a measuring angle and a steel ruler.

When you cut the metal, do not forget that the trimmed disk can be from 1.0 to 1.8 mm thick (depending on the brand), therefore, to maintain exact dimensions, cut not along the line, but close to it, but so that after the cut it was not visible.

It is best to order the assembly of the heat exchanger, especially from the system of interconnected tubes, to professionals, so that later no force majeure circumstances arise in the form of leaks. You can also order a stainless steel tank from them for heat accumulation and DHW.

As you understand, such a structure will have a sufficiently large mass, so solid fuel boilers with your own hands are best collected at the place of their installation, so that there is no need for transportation. Under the base of the unit should be poured concrete foundation (if there is none) or make it of fireclay bricks.

The grate is laid on the guides, and then the heat exchanger is mounted. The ribs are welded to the fuel chamber. After that, it remains only to sheathe the structure with metal sheets (walls and top), and between the walls we pour in the artificial sand that will hold and accumulate heat.

Conclusion

Although you will not achieve efficiency, like a factory-assembled boiler, but its price will be several orders of magnitude lower, even when some knots are made by third-party craftsmen. Do not worry - in the assembly of such a unit there are no insurmountable difficulties - success to you!