How to make a stove out of the pipe for the garage, bath,

It so happens that we live in a country where the average temperature is far from ideal, especially in the winter period. Heating devices are different and they work on different fuels, for example, in the garage they usually install a mobile version, which is able to quickly heat the room. In this article we will talk about how to make a stove out of the pipe with your own hands at no extra cost.

Existing industrial models, of course, have a number of positive characteristics, and some may be simply unique. However, many stops from purchasing them the high price of the product. Below, we consider models that cannot afford to hit you.

In fact, it will be proposed to produce a similar industrial version, only much cheaper in cost. A hand-made stove made of pipes can be used not only in the garage, but also in the bath.

Properties of the heater from the pipe

The banal truth says that there is nothing perfect in the world, therefore "there are spots even in the sun." The same can be said about our design. Whatever material is used in this case, you can always find not only advantages, but also flaws (see also the article How to equip a sauna furnace out of a pipe without any help).

We will assemble a metal furnace, so let's talk about its positive characteristics:

- There is no need to make a foundation, which must necessarily be when installing a stationary brick oven.

- It is quite mobile, so you can not be afraid of damaging it when transported to another place.

- The material has proven its strength and durability.

- Metal is not afraid of the high temperatures that you can create in the firebox due to the combustion of fuel.

- To maintain the temperature can use any combustible materials.

- Such a heating device, due to the rapid heat release by its walls, is able to warm the room in a short period. Therefore, it is often used in steam rooms.

- The design is simple, so even those who have not previously engaged in such work can make it with their own hands.

Of the negative points should be highlighted:

- The body material quickly cools down, so you often have to throw fuel into the furnace, which is not always convenient.

- You will need a welding machine and electricity, as well as some welding skills.

- Indoors, the warm air will spread unevenly, which will be noticeable, especially if its area is relatively large.

Design

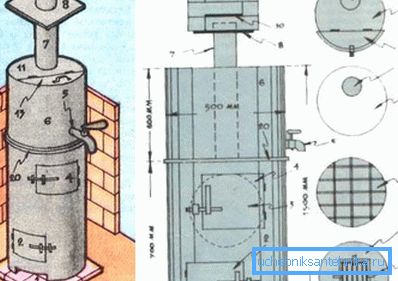

If you are all arranged in the previous paragraph, then you can move on. Now we will find out what basic elements our oven will consist of:

| Firebox | Designed for burning fuel. |

| Blew |

|

| Grid-irons |

|

| Water tank | Very convenient design, which allows you to always have a supply of warm water to wash your hands after the repair. It is usually placed above the stove, but sometimes it is also made part of it. |

| Chimney | Designed to divert gases from the smoke from the furnace outside the room. |

Tip: if you decide to use the structure from time to time or constantly in the bath, make a container from above, where you can put stones. This will significantly increase the efficiency of the furnace.

How to make

Training:

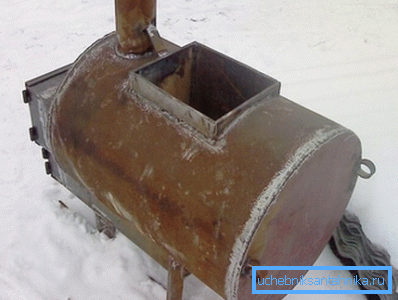

- Use for the manufacture of sheet metal or finished pipe of the appropriate size.

- The thickness of the metal should be from 8 mm. Since the rolled metal is more difficult to weld, so do not be upset if you do not get a round container. In this case, we are interested in exactly the pipe of the desired size, which can be vertical or horizontal, depending on the design.

- The diameter of the finished pipe - from 500 mm.

- Prepare two pieces - 600 mm and 900 mm long. The first is for the tank, the second is for the firebox.

Below is a guide that will help to clarify this issue:

- Make a hole for the blower at the bottom of the pipe so that the air entering it can create cravings and support burning.

- Make a small hinged door for him.

- The furnace will be located above the blower, the bottom of which are cast iron grates. To install them, you must first weld special supports to the device walls.

- Be sure to make the door for the furnace, its thickness may not be too thick, about 3 mm.

Tip: if you install stones on top of the stove, you will need a steel bottom for them, which you need to weld to the walls. It is necessary to make a passage for the chimney.

- Make a chimney of metal, hermetically welded it to the top of the furnace. Otherwise, gases from the furnace will start to enter the room.

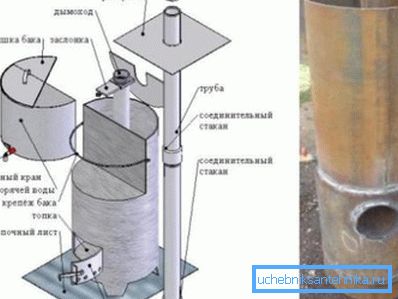

Making a water tank

As mentioned above, we will make it from the second workpiece 600 mm long.

- Weld the bottom to the pipe end using any steel, even 5 mm thick.

- Make a hole in the bottom of the chimney from the furnace.

- Weld the chimney thoroughly to the bottom of the tank to prevent water from flowing into it into the furnace.

- Install a removable cover on top of the design. It is removed for cleaning tanks.

For its production it is better to use two elements:

- one to attach to the chimney;

- the second is removable.

- Make a hole in the tank wall and install a drain valve in it.

Rocket stove

We have long been accustomed to the Russian stoves, the Dutch, bell and dvuhkolpak. However, engineering thought does not stand still, which resulted in a new trend in these heating devices.

Larry Viniarski invented a rocket stove or rocket furnace, which he developed for use in third world countries.

Consider the simple principle of its work:

- Firewood must be placed vertically in a special hole.

- Their ignition is carried out from below.

- The fire passes to a vertical chimney, usually made of metal, although sometimes they are made of brick. The first one is better because it warms up almost instantly, and the device doesn’t smoke so much during ignition.

Tip: for normal operation of the metal chimney should be well insulated.

- Top mounted to the top of the bottom of an ordinary metal barrel.

- When hot gases hit it, they begin to diverge on the sides, gradually going down.

- Then their path passes through a horizontal chimney, usually embedded in a cob sofa.

- The exit is a vertical exhaust pipe, which ordinary furnaces have in order to have traction.

Conclusion

From this article you learned that it is possible to make a real heater from the materials used, the cost of which will be minimal due to this. Metal pipe furnaces have proven their reliability and durability. Their various modifications successfully serve us in various areas of our life activity (read also the article Oven for a cauldron from a pipe with your own hands: simple and very affordable manufacturing methods).

The video in this article will help you find additional information on this topic.