How to make heating in a two-story house with high quality

Unfortunately, the question of how to carry out heating in a two-story house is asked after the building has been built, where there are no niches for laying communications. And sometimes even the wiring of electrical wires made a small section, so that there is dangerous to connect electrical appliances more than 1 kW power.

Nevertheless, it is necessary to heat the room, so we have to proceed from what is, that is, to build channels, to change individual parts of the wiring, and sometimes even to re-plan the rooms (it happened). We now turn our attention to two main types of heating - this is a water heated floor system and a radiator circuit, and a thematic video clip will help us.

Heating

Note. We can immediately say that a conventional heating and cooking stove for two floors will not be a sufficient source of heating - water boilers are needed here. Of course, it is quite possible to heat the room with the help of IPO (infrared film heating), but we are going to talk specifically about heat-transfer fluids.

Heaters

Perhaps the simplest solution for heating is a heating stove on two floors - in fact, it is no different from a conventional stove, it is only divided into two parts and it will take almost twice as many building materials. But to make such a design as the main source of heating is not very convenient.

Still, here for a good heating of the building it will take a lot of firewood and coal, which, moreover, will create garbage in the room and all this, not taking into account the hassle of fuel preparation, cleaning the ash pan and so on.

Note. Stove heating a two-story house is good in cases where it is auxiliary, since this method of heating takes a lot of time.

KLIVER-18P is a solid fuel boiler of direct combustion, which may well provide water heating for a two-story house with a living area of 180m.2, besides, the presence of the hob allows you to cook on it. The main type of fuel here is firewood and coal, which are easily loaded into the furnace - in terms of volume it allows you to hold a half-meter log, and coal can be loaded directly from a bucket. A solid fuel boiler is much more efficient than a stove for heating two floors - it needs less fuel and is designed a priori for the water heating circuit.

Of the solid fuel equipment, pyrolysis or generator sets, which are based on the Canadian furnace Buleryan, have recently begun to be used in a very large way. They are very economical.

For example, if you use firewood, then to support intense burning for a day, usually two armfuls are enough that are laid twice - one in the morning and the other in the evening. This efficiency is achieved through pyrolysis, that is, the residues from the combustion of fuel get into another chamber, where they burn out almost to the end, with almost no residue (such furnaces are used with or without a water jacket).

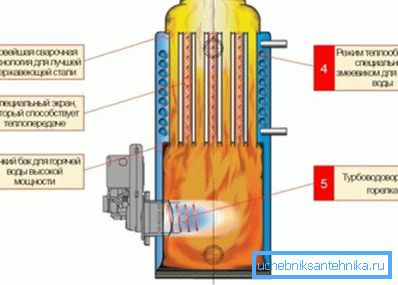

Heating units on liquid fuel, as a rule, work on diesel and fuel oil, therefore, they are also called diesel. There is an almost identical system of injection and ignition of the fuel, as in the engine.

Such boilers are suitable for any regions of our country, as they can work in all weather conditions, moreover, with full autonomous support. Although some of them need to be connected to 220V to operate the automatic control of the heater. The main disadvantage of such equipment is the high price of solarium, which you spend in the cold season - for example, gas or firewood will cost you much less.

Among electric heaters, electrode boilers Galan are now leading in many countries. And recently they are becoming more and more popular in the Russian Federation as economical and efficient heaters (compared to a heating boiler, it is more economical by 20%, and its efficiency is up to 98%).

The essence of heating is as follows - the fluid that is between the polar electrodes, more precisely, the ions, change their direction of movement 50 times per second (the current frequency in our network is 50 Hz), from which its temperature rises sharply. It turns out that the fluid here performs the function of an electric spiral heating element.

In most regions of the Russian Federation, it is possible to use natural gas, and even where there is no such possibility, they use liquefied propane for heating, since it is very efficient, profitable and convenient. Convection boilers operate in automatic mode (settings are set manually) and allow the owners to be absent for several months (there is a holiday mode) and their optimum operating temperature is 60-80? C, although this is not a prerequisite.

Efficiency largely depends on the heat exchanger, which is most often made of steel or chrome-nickel, but there is also iron and copper, by the way, the service life also depends on the material, since condensate (critical point 55-57? C) is corrosive to metal .

Let us say at once that for heating a two-story house with heated floors, a condensing unit is the most acceptable option for a heater. Its efficiency is about 105-107%, and the temperature range can vary from 30 ° C to 90 ° C without harm to the heat exchanger.

Nevertheless, this system is more suitable for low-temperature circuits (heated floors), where the average water temperature is 30-60? C, but the point of formation of condensate is 50-57? C. Consequently, at atmospheric burner condensate will always be there, and this is an additional 10-15% of thermal energy.

Of course, condensate is not used in its pure form, since there are acids there and it passes through a recuperator - it is to this additional source that the efficiency is due to such an overly high percentage.

Wiring methods

Note. Regardless of which one you prefer the heating boiler (stove), the layout of the circuit (radiators, underfloor heating, radiators plus underfloor heating) you will always remain the same. The only exception will be collector piping with the autonomy of devices.

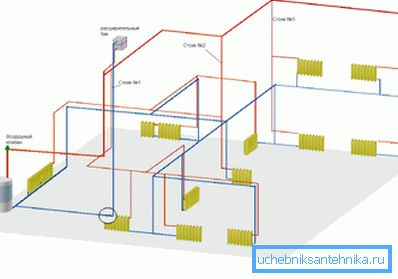

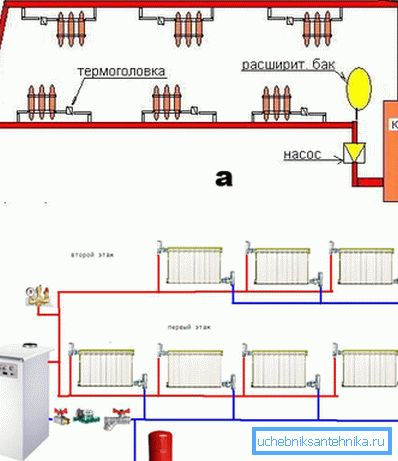

- Most often, the heating of a two-story house is done with the help of a radiator circuit, which can be either single-pipe or two-pipe, where the supply system and hot and drain (return) cold water are mounted separately from each other. The essence of the one-pipe principle is quite simple - through a looped main pipe under pressure created by the expansion of water and / or a circulation pump, the coolant enters the radiators through the outlets.

- This system has one significant disadvantage - the farther the radiator is located on the digital series, the colder it will receive water, which has already passed through other batteries and lost its temperature.. In some cases, shut-off valves are installed on the line between the inlet and outlet of the end battery connection, transferring the circulation flow through the heater sections. As practice shows, no more than 3-4 radiators can be used for a one-pipe heating circuit system without temperature loss.

- When using a two-pipe circuit, there is almost no heat loss, as the cooled liquid is discharged through another channel, therefore, if you even install three dozen radiators in a two-story house, then cooling at the end of the line will be almost imperceptible. Both in one and in the other case it is very important to ensure sufficient circulation, which is achieved either by the slope of the pipes or by the circulation pump, where the slope is not mandatory. In some cases, an additional pump is installed on the return pipe, which helps the built-in engine of the heating boiler.

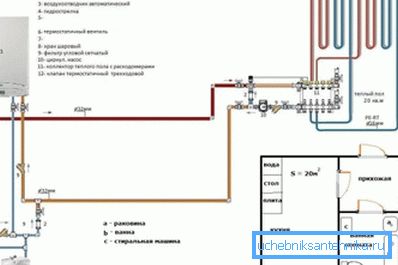

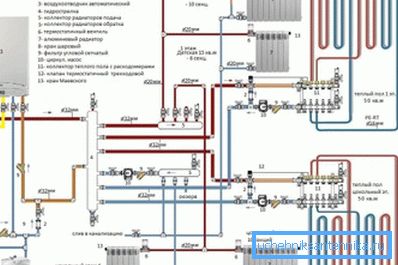

- If you want to heat a private two-story house with your own hands using a heated floor, then you, of course, are best to use a condensing boiler, and the connection scheme itself is very similar to a two-pipe radiator circuit, where instead of a battery there will be a spiral or a snake from a water pipe. In cases where the rooms are very large, it is best to divide them into two or even three wings, feeding each of them through a comb connected to the supply and discharge.

- Alternatively, you can install two combs on each floor (one for feeding, the other for return), but then, most likely, you will have to install very large combs, which is inconvenient. Such devices are better distributed across different parts of the building so that there are no more than 4-5 connections per node.

- In cases where the wiring of heating in a two-story house is carried out using different circuits, radiator and underfloor heating, then you need to use the principle of collector heating, where each group of heaters has an autonomous temperature. If for heating radiators you need a water temperature of 60-80? C, then for a heated floor it will be quite enough 30-50? C to achieve the same microclimate.

- But the coolant is supplied from the same boiler, so the flow temperature here is regulated by a three-way automatic valve, which, in fact, serves as a bypass. That is, the liquid is supplied, for example, with a temperature of 70? C to the radiators, whereas for the floor only 40? C is needed and in this case the valve automatically redirects the flow to the return. When the water in the floor circuit is cooled below 40? C, the valve produces a new portion of hot coolant.

Conclusion

If you have never done some such things yourself, then the information from this article will not be enough for you. In this case, for independent work, you will have to pay attention to the nuances of installing boilers, furnaces and circuits.