How to make heating in the garage of inexpensive and

Many owners of individual garages, as well as members of garage cooperatives, often use their garage not only for their intended purpose, to store their own car, but also as a storage room, home workshop, or a small service station. In such cases, sooner or later all have a question: how to make heating in the garage so that during the cold season it can maintain a comfortable temperature.

Individual heating in the garage

To perform such tasks, there are various ways of heating production areas and outbuildings, so in order to deal with this issue in detail, this article will describe the most common heating systems that can be used to heat individual or collective garages.

Each of them has its own advantages and disadvantages, and in order to choose the most suitable one for you, the reader will be offered detailed instructions that describe the main steps aimed at arranging the heating system in their own garage.

Warming garage

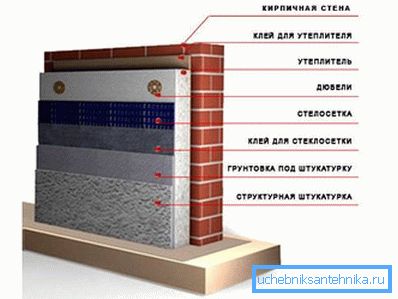

In order to achieve the most efficient operation of any of the existing heating systems, first of all it is necessary to minimize heat loss. For this you need to perform high-quality thermal insulation of exterior walls, ceilings, as well as the floor and metal gates.

It is best to keep warm capital garages that have their own foundation, the walls of which are made of brick or hollow concrete blocks, and the roof is made of reinforced concrete slabs or monolithic reinforced concrete floors.

- Outside, brick or concrete walls need to be sheathed with 50 mm thick foam sheets, and on top, with a special glue, reinforce the fiberglass mesh, which can be plastered and painted with facade paint.

- If it is not possible to make external insulation, you can cover the walls with a thick layer of plaster from the inside, or install a frame made of metal profiles, fill the space between them with mineral wool, and sew up with drywall sheets on top.

- To insulate the floor during the construction of the garage, it is necessary to pour a sand cushion 50-100 mm thick on the ground, then lay a waterproofing made of polyethylene film, fill in a layer of expanded clay 100-200 mm thick, or put sheets of extruded polystyrene foam 50 mm thick. After that, lay a reinforcing grid with a mesh size of 50 mm, and pour a concrete screed with a minimum thickness of 50 mm.

- Thermal insulation of the roof is carried out in a similar way: along the perimeter of the ceiling, 3-4 layers of brickwork should be laid out in half-brick, a layer of expanded clay or coal slag 150-200 mm thick should be laid on the ceiling, and 20-30 mm thick concrete should be poured from above. After hardening and drying of the concrete, cover the surface with rolled waterproofing material in one or two layers.

- To insulate the door, around the perimeter of each leaf, it is necessary to fasten a frame made of metal profile or bar, section 50-80 mm, put mineral wool sheets inside, and sew upwards with plywood, OSB, or other moisture-resistant sheet material.

Tip! If there is a basement or inspection pit in the garage, due attention should also be paid to their insulation, because of the temperature difference they will constantly form condensate.

Varieties of heating systems

In order to make the right decision what kind of heating is better for a garage, one should take into account the influence of certain factors, for example, its location, distance to the house, presence of utility lines (electricity, gas, water supply), frequency and intensity of use of the heating system, etc.

Given the specificity of the garage room, the most optimal from the point of view of safety and energy efficiency, we can consider the following types of heating systems:

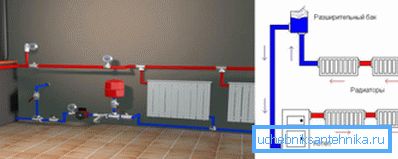

- Water heating is the most efficient, but it makes sense to use it to heat large areas.. For heating water, you can use a domestic heating gas boiler, as well as a boiler that runs on solid or liquid fuel.

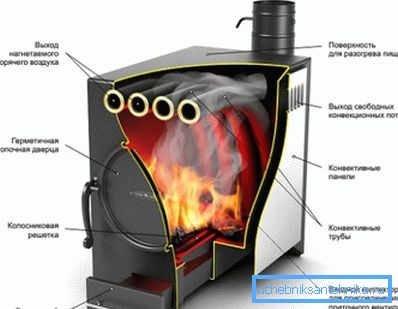

- The air heating system is a conventional stove, “stove”, working on solid or liquid fuel, the heated part of which, for better heat exchange, is forcibly blown by the air flow from the injection fan. In addition, such a furnace, installed in the room, emits thermal radiation, and also contributes to the convective movement of air masses.

- Electric heating is the simplest option, besides this method allows you to quickly heat up the room, but the price of electricity for electric heaters will cost significantly more than the cost of fuel for other heating devices.

Tip! If the garage is located in close proximity to the house, the water heating system can be connected to the autonomous heating system of a residential house through a special tap equipped with a mechanical thermostat.

Solid fuel heating stove

Having decided on how to heat a garage in winter, and making a choice in favor of an air heating system, it is easy to make a simple stove, “stove”, which uses wood, coal, and other types of solid fuels from cutting a thick-walled metal pipe 500-800 mm in diameter .

- Using a detachable machine or a gas cutter, cut a part of the pipe from 600-800 mm high from a flat end.

- At a distance of 30 mm from the bottom edge, cut a rectangular segment with a size of 250x150 mm. This hole in the pipe will be used as a blower, and the cut segment will serve as its door.

- At a distance of 250 mm from the bottom edge, cut a rectangular hole 300x200 mm in size, which will be used to load fuel, and the cut segment will serve as a fire door.

- Inside the pipe, in the interval between the firebox and the blower, weld a frame from a metal corner 32x32 on which the grate will lie.

- Weld the circles cut from a thick-walled metal sheet, the diameter of which should be slightly larger than the outer diameter of the pipe, to the lower and upper end of the pipe, while the branch pipe for the chimney with a diameter of at least 100 mm should be welded into the upper circumference.

- Swivel hinges to which the firebox and blowing doors are to be welded are welded to the outer part of the pipe, with clamps pre-installed to hold them in the closed position.

- Weld metal support legs from a pipe or a corner to the lower circumference, install the grates into the furnace, and tightly connect the exhaust pipe to the upper branch pipe.

Tip! To ensure normal draft in the furnace, the chimney pipe must end at such a height that the vertical distance from the blower to the outlet opening is at least 4 m.

Waste Oil Heating Furnace

Owners of garages who have a car service center or a motor transport company nearby, thinking about the question: how to heat a garage in winter, you should pay attention to special furnaces and boilers that run on liquid waste oil.

The fact is that at the posts of replacement of engine oil, this type of fuel can be recruited free of charge, therefore for those who have such an opportunity, an oven with used oil will be the most economical option of garage heating.

.

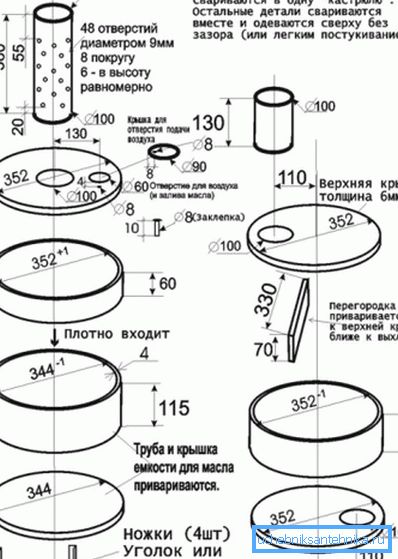

The design of this furnace consists of two hermetic chambers of a certain volume, interconnected by means of a steel pipe with openings for air intake. One of them is designed to heat and evaporate the oil, and the second is the combustion chamber, in which the burning of oil vapor in the flow of atmospheric air takes place.

Making such furnaces with your own hands must be carried out in strict accordance with the technical drawings. Moreover, in the process of work it is important to ensure a tight connection of all parts and absolute tightness of the weld; therefore, it is better to perform such work in specialized workshops that have the necessary equipment for metal processing.

Tip! Before heating the garage with such furnaces in winter, it is important to ensure free flow of fresh air to the perforated pipe in which the oil burns, as this process consumes a large amount of oxygen.

Electric heating

In cases where the owner thinks about the question: how to heat the garage in winter, after the onset of cold weather, and there is no time to install the heating system for the furnace, for heating it in winter, you can use electric heaters.

The main advantage of this method is that to connect electric heaters, it is enough to use an ordinary household electrical network with an alternating current of 220 volts.

As for heating devices, in the conditions of the garage it is most efficient to use the following types of heaters.

- Fan heaters or heat guns provide rapid heating of the room due to the forced blowing of air through the spiral of the heating element.

- Oil radiators, due to the high heat capacity of the oil, are capable of maintaining the desired temperature for a long time.

- Electric convectors provide uniform heating of the air due to the convective movement of air masses through a closed heating element.

- Infrared heaters emit electromagnetic waves of a certain frequency, which heat the surrounding objects in the line of sight.

Tip! Using this type of heating, it should be remembered that all electrical heating devices consume a large amount of electricity, and create a high load on the internal electrical wiring.

Conclusion

In addition to the methods described above, there are still various gas heaters that operate from a conventional domestic gas liquefied gas cylinder, but an open flame is often used in their work, therefore, according to the requirements of fire safety regulations, they should not be used in the garage.

For more information on the subject of interest, you can watch the video at the end of this article, or read other articles in this section on our website.