How to make steam heating in a house using a brick oven

When choosing a heating system, it is recommended to dwell on the one for which fuel is abundant in this area. Since gas has not yet reached remote places, many are trying to install heating devices that use solid or liquid fuels. Our task today is to explain how to do steam heating with your own hands using a heat exchanger installed in a brick oven.

The heat carrier in such a system will be either water or steam. Today we are interested in the second option, although these two systems are often confused with each other. They have differences and are quite serious, therefore in residential buildings it is allowed to use only the water circuit. This is due to the unsafe operation of steam heating, when it is necessary to heat the liquid to a temperature above 100? С.

At the same time, its price is lower than that of water, and modern protection measures help avoid catastrophic consequences. However, the installation of steam heating, for example, from a brick furnace requires a lot of time and effort. Below we learn about this in more detail.

Principle of operation

Now consider the difference between the two systems, so that you are not confused. It will also be told about the advantages and disadvantages of such a space heating system.

Let us consider in more detail what steam heating is:

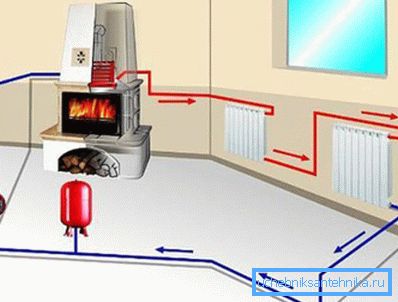

- In a tank, water is brought to a boil, which gradually turns into steam.

- Then it goes through the pipeline to radiators, which give it heat to the room.

- In batteries, the heat transfer fluid condenses.

- The resulting water flows into the expansion tank and enters the heat exchanger again.

| Benefits |

|

| disadvantages | Consider the negative factors of this heating system and how they can be eliminated:

|

Tip: the generator for steam heating can serve as a boiler, working on waste oil. Such systems are often installed in utility rooms and in the garage.

Please note that it is undesirable to use a brick oven with a steam generator for cooking, because it cannot be used in the summer. It is better to come up with an alternative at this time. It should also not be used for plastic pipelines, it is not intended for such temperature conditions.

Mounting Patterns

Below we consider the most frequently used options:

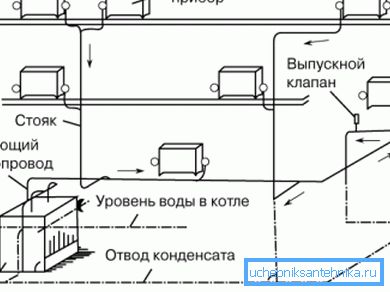

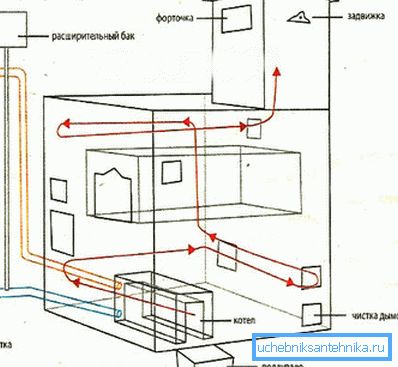

- Apply the natural and mechanical circulation system coolant. In the first case, the heat exchanger must be placed below the level of all pipes and radiators at an angle. In the second, the installation of a pump is required, which ensures uninterrupted movement of the heat exchanger.

- The one-pipe heating system in operation uses the principle of serial connection of radiators when the coolant moves through the pipeline, moving from one register to another. As a result, the first is the hottest, at the same time, the last - almost cooled down. We recommend using such a scheme for small rooms up to 80 m2.

- The two-pipe system is well suited for large houses, in particular, two-story cottages. In this case, the radiators are connected in it in parallel, using supply and condensing pipes. The coolant in this scheme is supplied to all batteries with the same temperature, so it does not have time to cool.

Independent device of steam heating from a brick oven

Prepare equipment and materials:

- provide radiators under each window;

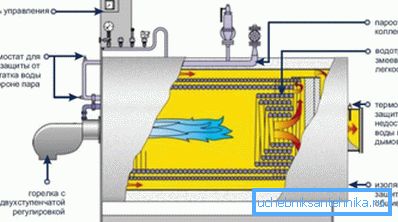

- heat exchanger - steam generator or water tube boiler;

- pipes for steam and condensate. It is advisable to use galvanized steel or copper;

- connectors, elbows, pipe clamps, valves - valves for air relief, valves;

- battery brackets;

- hydraulic lock for steam line drying;

- reduction and cooling unit;

- to reduce the pressure in the system - pressure reducing valve;

- welding machine;

- pump;

- condensate collection tank.

Tip: recommend expensive equipment to rent.

You can do it yourself or order the heat exchanger for a brick furnace:

- Prepare metal pipes with a wall thickness of 2.5 mm, as well as a welding machine.

- Connect them in the form of a coil, while monitoring the quality of welds. Approximate calculation - 1 m2 of the surface of the coil can give up to 9 kW.

- Check for leaks after fabrication. We do not recommend using water, as slag inclusions will fall off under high pressure and fistulas will appear.

It is better to use a method called "kerosene on chalk." In this case, circle all the welds with chalk and pour kerosene inside the structure. Mel will darken even in the case of the smallest pore, as kerosene will leak into it.

Process

Below is a guide that will help you understand it:

- Install the heat exchanger in the furnace furnace during the laying phase.

- According to the pre-drawn scheme under the windows mount the batteries. By installing on each tap for air release.

- Connect the supply and return pipelines to them.

Tip: when natural circulation provide a small slope at the rate of 3 mm per 1 m.

- Install safety valves in front of each register for safety reasons, as well as one valve in front of the entire system.

- Place a pressure reducing valve and cooling equipment at the beginning of the pipeline.

- At the end of the pipeline, place a condensate tank that should drain back to the heat exchanger on an incline.

Tip: do not use for such purposes membrane expander, because it is designed for temperatures up to 85 ° C.

- If a circulation pump is provided, install it in front of the furnace in the return pipe.

Recommendations of specialists:

- If a brick kiln is equipped with a heat exchanger, more soot is formed in the chimney than without it, so it must be cleaned more often.

- With the natural circulation of the coolant, the furnace should be placed in the basement, then the condensate will flow freely to the lowest point.

- Always install the valve - this will prevent a possible accident and the system itself will be more secure.

- Please note that if you use a forced system with an electric pump, in the event of a power outage, it will be very difficult to stop the operation of the furnace.

- In a wooden house, heating with steam is established in the same way as in a brick house. You only need to comply with fire safety requirements, protecting the wood from overheating.

Conclusion

From the article you learned how to make steam heating, as well as the fact that its use in a residential private house is cheaper than water, although it is more dangerous to use. Therefore, it is necessary to strictly follow the instructions and provide the system with special equipment that will increase its safety.

You can order a heat exchanger from specialists or do it yourself. Installation and connection of radiators is not difficult. The video in the article will help you find additional information on this topic.