How to make the calculation of heating pipes heating: take

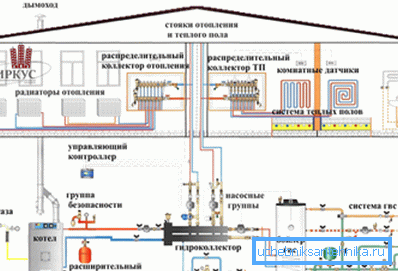

When installing a heating system in a private house or apartment, the main goal is always to extract the maximum efficiency from the equipment so that the money spent is spent on heating the room.

This is possible with proper selection:

- not only the system and radiators;

- but also the diameter of the pipes;

- as well as the material of their manufacture.

Let's learn how to make such calculations, pay attention to which materials are more profitable and watch a video clip on this material.

Heating pipes

- Diameter and hydraulic calculation of pipelines is possible only if there are basic parameters for this, such as:

- Manufacturing material, for example, steel, copper, cast iron, chrysotile cement, polypropylene.

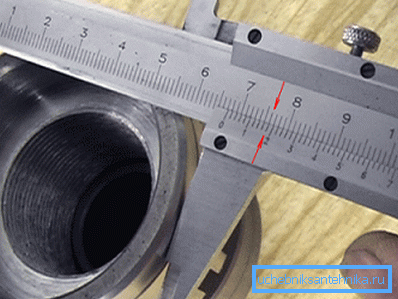

- Inner diameter.

- Data on the diameter and material of fittings and fittings.

- Wall thickness of pipes, fittings and fittings.

- It is not clear where the opinion emerged that with an increase in the diameter of pipes, the quality of heating increases, as with an increase in the area of the pipeline, heat transfer increases. Theoretically, this, of course, is very much like the truth, but in reality everything looks different.

- First of all, for large diameter pipes it is necessary to pump into the system a large amount of coolant that needs to be heated. Consequently, the consumption of energy consumed (electricity, gas, liquid or solid fuel) increases. And the pipes themselves are not a heating device (in radiators for heating, the convection method is used, that is, the efficiency increases significantly), it turns out that the consumption of materials and energy is not justified.

- In addition, an increase in fluid in the circuit leads to a decrease in pressure in the system, therefore, you will have to install an auxiliary circulating pump for the heating system upon return, which again incurs certain costs. Of course, even with a large diameter of the contour pipes, it is quite possible to reach the desired temperature in a heated room, but the price for material and energy sources will be too high.

Attention! For optimal installation and operation of the heating system (when selecting the diameter), the pressure in each circulation ring should be 10% higher than the losses caused by the hydraulic resistance.

Diameter determination

For professional calculations on the diameter of heating pipes, heating engineers use a large number of formulas and such calculations are usually needed for projects of multi-storey residential and public buildings, enterprises and other institutions. For your home, you are unlikely to need such exact figures, therefore, we offer you a simplified scheme that every plumber can use.

The formula for such calculations is as follows: D = v354 * (0.86 * Q /? T) / V, and now we just need to substitute the values of the parameters under the letters.

Here:

- D is the diameter of the pipe (cm);

- Q - load on the measured area (kW);

- ?t is the temperature difference in the flow and return pipe (t? C);

- V - coolant velocity in the system (m / s).

Note. If on the coolant supply at the boiler its temperature is 80? C, and on return at the boiler 60? C, then in this case the value? T will be equal to? T = 80-60 = 20? C.

| Consumption | Pipe capacity (kg / h) | ||||||||||

| Du pipe | 15 mm | 20 mm | 25 mm | 32 mm | 40 mm | 50 mm | 65 mm | 80 mm | 100 mm | ||

| Pa / m | mbar / m | ?0.15 m / s | ?0.15 m / s | 0.3m / s | |||||||

| 90.0 | 0,900 | 173 | 403 | 745 | 1627 | 2488 | 4716 | 9612 | 14940 | 30240 | |

| 92.5 | 0.925 | 176 | 407 | 756 | 1652 | 2524 | 4788 | 9756 | 15156 | 30672 | |

| 95.0 | 0,950 | 176 | 414 | 767 | 1678 | 2560 | 4860 | 9900 | 15372 | 31104 | |

| 97.5 | 0.975 | 180 | 421 | 778 | 1699 | 2596 | 4932 | 10044 | 15552 | 31500 | |

| 100.0 | 1,000 | 184 | 425 | 788 | 1724 | 2632 | 5004 | 10152 | 15768 | 31932 | |

| 120.0 | 1,200 | 202 | 472 | 871 | 1897 | 2898 | 5508 | 11196 | 17352 | 35100 | |

| 140.0 | 1,400 | 220 | 511 | 943 | 2059 | 3143 | 5976 | 12132 | 18792 | 38160 | |

| 160.0 | 1,600 | 234 | 547 | 1015 | 2210 | 3373 | 6408 | 12996 | 20160 | 40680 | |

| 180.0 | 1,800 | 252 | 583 | 1080 | 2354 | 3589 | 6804 | 13824 | 21420 | 43200 | |

| 200.0 | 2,000 | 266 | 619 | 1154 | 2488 | 3780 | 7200 | 14580 | 22644 | 45720 | |

| 220.0 | 2,200 | 281 | 652 | 1202 | 2617 | 3996 | 7560 | 15336 | 23760 | 47880 | |

| 240.0 | 2,400 | 288 | 680 | 1256 | 2740 | 4176 | 7920 | 16056 | 24876 | 50400 | |

| 260.0 | 2,600 | 306 | 713 | 1310 | 2855 | 4356 | 8244 | 16740 | 25920 | 52200 | |

| 280.0 | 2,800 | 317 | 742 | 1364 | 2970 | 4456 | 8568 | 17338 | 26928 | 54360 | |

| 300.0 | 3,000 | 331 | 767 | 1415 | 3078 | 4680 | 8802 | 18,000 | 27900 | 56160 | |

Proportional relationship between throughput and pipe diameter

Calculation of thermal power (load)

To determine the optimal thermal capacity of the heating system of a private house, you can use the following formula: Qt = V *? T * K / 860.

Now, again, you just have to substitute the numerical values in place of the characters and here:

- Qt is the required heat energy output for a given room (kW / h);

- V - volume of the heated room (m3);

- ?t is the temperature difference in the flow and return pipe (t? C);

- K - heat loss coefficient of the room (depending on the type of building, wall thickness and thermal insulation);

- 860 - conversion to kW / h.

In the private sector, buildings can be very different from each other, but, nevertheless, the following values of heat loss coefficient (K) are often used there:

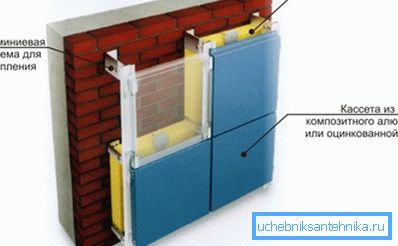

- If the architectural structure has a simplified construction (wood, corrugated metal) and there is no insulation, then K = 3-4;

- Simplified construction of an architectural structure with a low degree of thermal insulation, for example, laying one brick or a 405x400x200 mm foam block — here K = 2-2.9;

- In standard architectural structures (laying in two bricks and a small number of windows and doors, the roof is standard) K = 1-1.9;

- With a high degree of thermal insulation for standard architectural structures with a small number of windows and doors and a warmed roof and floor, the instruction indicates that K = 0.6-0.9.

If you need to calculate the pipe diameter, then, as noted above, you need the value of the temperature difference between the street and the room. Indoors, either the room temperature (18-20? C) or the one that suits you best is taken as a reference point, and from the street you need to substitute the average value that is accepted for your region.

For example, your room has a volume of 3.5 * 5.5 * 2.6 = 50.05 m3 and it is well insulated, that is, there are thick or insulated walls, the floor and ceiling are insulated, and we use the coefficient of 0.9. In the Moscow region, the average air temperature in winter is -28? C, and for a microclimate in the room we take a value of 20? C, then the value of? T will be equal to 28 + 20 = 48? C. In this case, Qt = 50.05 * 48 * 0.9 / 860? 2.5 / hour.

Coolant speed

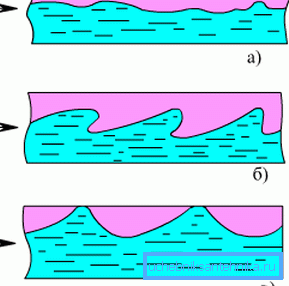

Note. The minimum coolant velocity for heating systems should not be less than 0.2-0.25 m / s. In cases where the speed falls below this value, air begins to emit from the liquid, which contributes to the formation of air plugs. In such cases, the efficiency of the circuit may be partially lost, and in certain situations this may lead to complete inactivity of the system, since the flow will stop altogether and this will happen when the circulating pump is running.

| Internal diameter of pipes | Heat flow (Q) at? T = 20 Water consumption (kg / h) at movement speed (m / s) | ||||||||||

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | 1.1 | |

| eight | 40918 | 81835 | 122853 | 163570 | 204488 | 2453105 | 2861123 | 3270141 | 3679158 | 4038176 | 4496193 |

| ten | 63927 | 127755 | 191682 | 2555110 | 3191137 | 3832165 | 4471192 | 5109220 | 5748247 | 6387275 | 7025302 |

| 12 | 92041 | 183979 | 2769119 | 3679158 | 4598198 | 5518237 | 6438277 | 6438277 | 8277356 | 9197395 | 10117435 |

| 15 | 141762 | 2874124 | 4311185 | 5748247 | 7185309 | 8622371 | 10059438 | 11496494 | 12933556 | 14370618 | 15807680 |

| 20 | 2555110 | 5109220 | 7664330 | 10219439 | 12774549 | 15328659 | 17883759 | 20438879 | 22992989 | 255471099 | 281021208 |

| 25 | 2992172 | 7983343 | 11975515 | 15967687 | 19959858 | 239501030 | 279421202 | 319341373 | 359261545 | 399171716 | 439091888 |

| 32 | 6540281 | 13080562 | 19620844 | 261601125 | 327001406 | 392401687 | 457801969 | 523202250 | 588602531 | 654012812 | 719413093 |

| 40 | 10219439 | 20438879 | 306581318 | 408751758 | 510942197 | 613132636 | 715323076 | 817513515 | 919693955 | 1021884334 | 1124074834 |

| 50 | 15967687 | 319341373 | 479012060 | 638682746 | 798353433 | 958024120 | 117654806 | 1277355493 | 1437026179 | 1596596866 | 1756357552 |

| 70 | 112951345 | 625902691 | 938854037 | 1251815383 | 1564766729 | 1877718074 | 2190659420 | 25036110768 | 28165612111 | 31295213457 | 344247148013 |

| 100 | 638682746 | 1277355493 | 1916038239 | 25547110985 | 31933813732 | 38320616478 | 44707419224 | 51694121971 | 57480924717 | 63867727463 | 70254430210 |

Table for determining the pipe diameter

Note. The density of water at 80? C is equal to 971.8 kg / m3.

The fluid velocity in the heating circuit can be from 0.6m / s to 1.5m / s, but in cases where a larger value is observed, the hydraulic noise in the system is significantly reduced, therefore, we will take the speed of 1.5m / s as starting value.

When we have all the necessary values, we can substitute them into the formula D = v354 * (0.86 * Q /? T) / V, in which case we will have D = v354 * (0.86 * 2.5 / 20) / 1 5? 1,34, then we need a pipe with an inner diameter of 14 mm

Of course, when you do a heating system in your own house with your own hands, then the probability that you will use formulas for calculations is negligible, but in this case there is a manual for you in the form of tables located in this article. In addition, the table takes into account the type of fluid circulation, which can be forced or natural.

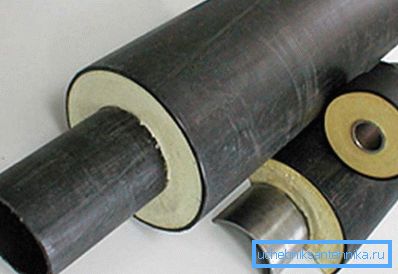

Nowadays, most often (especially in the private sector), radiator circuits, as well as the distribution of heating pipes to floor heating systems, are made of polypropylene. Of all used in this case, this material has the lowest thermal conductivity, but, nevertheless, in those places where the pipes pass through the cold areas, they need to be warmed.

Conclusion

In conclusion, we can say that the most commonly used outer diameter of polypropylene pipes for heating circuits in the private sector is 20, 25.32 and 40 mm. Heaters to the radiators are generally made with a cross section of 20 mm, occasionally 25 mm, and thicker pipes are used as risers.