How to make the installation of the heating of plastic pipes

Permission to install autonomous heating in apartments of multi-storey buildings allowed finally to disconnect from the difficult to predict central heating. There was no particular choice - either metal pipes or metal-plastic, because nobody has heard about polypropylene with a soldering iron. The second option seemed more attractive - it didn’t spoil the look of the apartment, and you can do the installation of the heating yourself without much difficulty, and reminds the children's designer.

Metal pipes are used not only for heating, but also for hot water. They have proven themselves to work only from the good side, besides they have high efficiency due to their temperature and hydraulic characteristics, and also meet all hygienic requirements. Below we will talk about their advantages, features of labeling and self-installation, without involving installation organizations for heating.

Product Benefits

From the name we can conclude that the pipes are produced in a combined way, using metallic and polymeric materials. Thanks to this combination, it is possible to guarantee the reliability and durable operation of the products. Let's consider the main advantages of pipes from metalplastic:

Easy installation - no need to use welding equipment, fittings are used to connect the elements. Therefore, the pipeline can be assembled without problems even in places where electricity is not available.

There is no need to look for an installation organization for heating, you can do everything yourself:

- a small mass of products, so when working with them you do not get tired;

- high corrosion resistance - the pipes are not subject to rust, and the smoothness of the internal passage maintains the entire life cycle, guaranteeing the required flow of liquid;

- good flexibility to a certain point, so the instruction requires to be careful when turning 90 ?, in this case it is better to use the corners;

- long life of the pipeline - manufacturers guarantee about 20 years, although nothing prevents to easily increase the parameter by 2 times;

- resistance to temperature change inside the system;

- no linear expansion when heated, so the SNiP allows the use of pipes in various industries;

- pipelines can be laid in different planes, including along the floor or along the wall;

- chemical inertness of the surface that does not allow the formation and development of mold and life-threatening fungi inside the pipes;

- the price of products is available to wide sections of consumers, it is much lower than steel or copper analogues.

How are m / n pipes labeled

Symbols on the product make it possible to determine whether they are suitable for heating or not, whether you choose the diameter of the pipes or it is better to search.

Marking includes the following:

| Type of polymer material | Today use:

|

| Diameter | Manufacturers offer consumers pipes with an internal section of 12-90 mm. Most often for heating they use - O16 (for connection to batteries), O20 (for the main channel in apartment autonomous heating). |

| Type of stitching | It is produced in various ways, while using:

|

| Nominal pressure | It is denoted by the letters PN and indicates the parameter at a temperature of +200? С. |

| Additionally | Also indicate:

|

Tip: when buying a plastic pipe, require a certificate of quality, it will guarantee that this product will last the period specified in the manufacturer’s warranty.

Installation of pipelines from m / p pipes for heating

Before starting work, it is necessary to learn how and how to interconnect the elements of the heating system. Below we consider these issues in more detail.

Connection options

We have already said above that it is easy to work with metal-plastic pipes, since you do not need electricity for this, as well as special equipment.

All connections are made using special fittings (which in English means to fit or assemble), the range of which is quite varied, most often found:

- tees;

- transitional and connecting couplings;

- squares.

Thus, it is possible to assemble disparate elements on pipeline sections into a single system using splicing or branching. The method is quite convenient and high quality, ensures durability, reliability and high quality of the heating system. Thanks to different models of fittings, it is possible to make independently competent installation of the most complex pipe wiring scheme.

Depending on the method of fasteners on the pipes, fittings are produced:

- threaded;

- glue;

- compression

To connect parts of the metal-plastic pipeline, use crimp and press fittings.

Work with crimp fittings

It is necessary to prepare the following tool for heating installation:

- spanners the necessary sizes;

- face picker - it will be required for stripping the ends of pipes;

- pipe bender - change the shape of products;

- pipe cutter - adjust the size.

The principle of installation of crimp fittings is to squeeze the crimp ring with a tightening nut, which allows you to reliably fix the place of the joint. The cost of these fittings is low, but due to its collapsible design, you can create a detachable connection. Thereby, after dismantling the old pipes they are allowed to be used again.

Among the shortcomings it should be noted:

- the need for periodic tightening of the tightening nuts, usually a year will have to do this 3-4 times for prevention. If a leak occurs at the junction, then more often;

- there must be constant access to pipe connections, so making a hidden gasket is difficult, and often impossible.

We connect pipes press fittings

- Press fittings are more popular, which can be used for the installation of not only water supply and heating systems, but even gas.

- The design consists of a sleeve inserted into the housing, and the crimping is performed using a special tool.

- Products provide connection reliability and high coefficient of tightness.

- Have a good appearance.

- The heating system can be laid in a hidden and open way.

Disadvantages of equipment:

- high cost when compared to other types of products;

- connections are obtained one-piece, which can not be dismantled without violating their integrity.

For installation, you will have to rent or purchase an electric or hand tool - a gun.

Installation of m / p pipeline for heating

Below we suggest you use the recommendations of experts.

They will help you when you carry out an independent installation of the heating circuit of plastic pipes:

- Choosing products, do not be in a hurry and check their labeling well. Pipes are intended for heating, which can operate at a coolant temperature of 95 ° C and a pressure of 6.6 bar and above;

- when fixing pipes on the walls, leave an interval of no more than 500 mm between fasteners so that during operation they do not sag and do not disturb the movement and circulation of the coolant;

- not recommended for installation outside the room. If the system freezes, they may burst, which will cause an emergency shutdown of the heating boiler, as well as the replacement of the entire heating system.

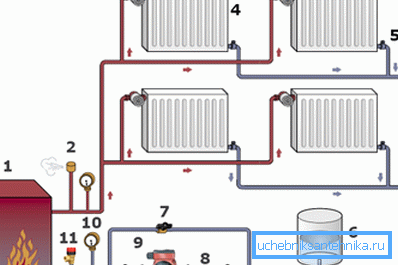

Heating circuit

We recommend in this case to use two-pipe wiring, when one pipe is the feed and the second is the return. If the house is two-storey, for each it is necessary to make an independent bottling - spend two pipes on the first floor and two pipes on the second. Put the pipes in the installed waterworks with the boiler.

Tip: if you interconnect the supply and return flow, and then bring them to the boiler through a common pump, the system will work, but its capacity may not be enough due to the large number of consumers.

In drawing up the layout of the pipes, it is necessary to proceed from the fact that the heat generator and the waterworks will be located as low as possible of all radiators. In this case, note that moisture is contraindicated in the electric boiler, so choose the driest place for it.

For a uniform flow rate of heat carrier and heat distribution over the batteries, we recommend that after each radiator, except the end ones, reduce the diameter of the pipeline. Installing a heating system using this method is most common along with radial layout. The latter, although it has some advantages, is much more expensive due to the large number of pipes used.

Conclusion

Heating with metal pipes is a good solution, especially where it is not possible to use other materials. It is also interesting because, thanks to the crimp fittings, you can quickly dismantle it, replacing it in whole or in parts.

For this you do not need to use any special tools, rather ordinary wrenches of the desired size. Installation of the heating system does not take much time and it can be easily done independently. Video in the article will provide an opportunity to find additional information on the above topic.