How to properly tie the heating boiler

One boiler can not provide you with the heat in the room, for this it is necessary to make it strapping. Then, the heat generated by it can flow through the pipelines to the heating devices, which will give it to the atmosphere of the rooms. It should be noted that the piping scheme may vary depending on the type of heating boiler used in the system, its installation and the availability of additional equipment. Therefore, keep in mind that there are no universal options.

Choosing pipes

Each material has its own characteristics that affect its performance. When choosing pipes for tying the boiler room, pay attention to their thermal insulation properties, what difficulties may arise during installation, and whether the price of the products is right for you.

Consider the most popular solutions:

| Polypropylene | An ideal material for the manufacture of strapping, although it also has its drawbacks. Benefits:

The disadvantage is the maximum temperature of the coolant to 95? С. |

| Copper | Work on strapping requires a certain professionalism. The cost of material is high. Advantages of the copper pipeline:

Disadvantages:

|

Solid fuel boiler

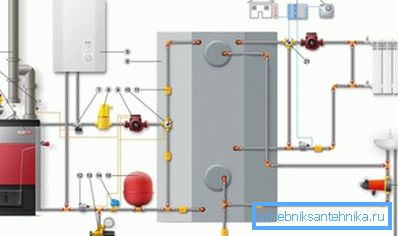

The design of the equipment and its principle of operation affects the connection to the heating system. It should be noted that the simultaneous strapping of solid fuel and electric boiler has its own nuances, affecting their operation and performance.

Let us consider in more detail how the solid fuel boiler should be tied with its own hands:

- The return temperature can not be below the "dew point" or 55? С. Otherwise there will be a large amount of condensation. We recommend for this reason to make the strapping of a solid-fuel double-circuit wood boiler with copper, which is much better than polypropylene. It has a better thermal conductivity, so it will reduce the amount of condensate.

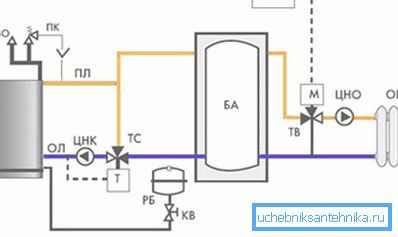

- If necessary, you can connect several boilers to one network, which will require additional equipment.. For example, a heat accumulator will be needed when tying two wood solid fuel boilers. This scheme has long been used in the West, allowing you to save excess heat in a special tank, resembling a thermos. When the temperature of the coolant drops, the heat starts to get out of the tank. It is also necessary to provide in this case two valves - a thermomixing, heat carrier preventing overheating, and a subversive. Although the installation of the heat accumulator will require additional costs, in the end all investments will pay for themselves fairly quickly due to fuel economy.

- Use for strapping polypropylene pipes is possible under certain conditions.. For example, they should be heat resistant and reinforced, as the coolant will always have a temperature of more than 60? С. Well proven products with optical fiber with aluminum rod. At the same time, the installation instructions do not require, as is the case with copper, the use of electrical insulation and a ground loop.

Gas equipment

In this case there are no ready-made solutions, since everything depends on the use of water-heating equipment, as well as the number of individual heating systems.

Below we offer you the recommendations of experts:

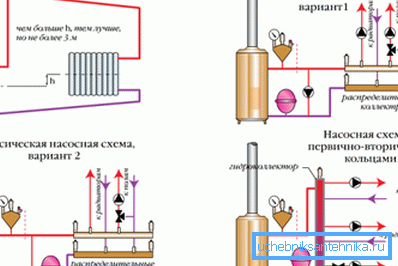

- Heated floor and radiators. In this case, the gas heating boiler should be tied strictly using a hydraulic needle or a water distribution manifold. The boiler heats the coolant, and the circulating equipment installed inside it pressurizes directly in the area from it to the collector. After the arrow, additional circulation pumps are used for each heating circuit.

- The binding of the wall equipment with copper pipes is made according to the calculated cross-section of the pipeline. The same applies to polypropylene pipes. But, if for heating 60 m2 of housing the cross-section of a copper pipe is 20 mm, the diameter of polypropylene must be within 25–32 mm.

- The installation of the accumulating tank is an innovation, but so far it has not become widespread. In this case, it is recommended to use it for tying the floor gas boiler in the case of using cast iron units. They are afraid of a sharp decrease in temperature, and the heat accumulator makes it possible to smooth out such peaks.

- For tying a mounted gas boiler with 2 circuits, no additional equipment is required. The design and so fully equipped. You just need to connect the device to the radiators of the heating system at home. When tying a gas wall boiler with a single loop of polypropylene to the heating system at home, work is carried out in a similar way. Only in this case only the heating system is taken into account.

- For outdoor models, installation of additional equipment is usually required. For example, for the dual circuit will need circulation pumps, coarse and fine filters, expansion tank. It may also be necessary to install and hydraulic arrows.

Tip: if a single-loop gas-fired gas boiler of a volatile type is connected to the heating system, a bypass must be installed, which will control the circulation of coolant, which should not be stopped after a power outage.

Firewood-electricity boiler

Equipment binding is performed in a parallel and sequential way. This is necessary to ensure continuous heating of the coolant in the system.

To do this, do the following:

- The main source of heat is a solid fuel boiler. It should ensure normal heating of the coolant throughout the day.

- At nightfall and after a fuel burnout, the electric boiler should automatically turn on, continuing to heat the coolant in the system until the main boiler starts up again.

There are several ways to achieve this, but the main one is to use an ejector. In this case, a prerequisite - the boiler must be installed at a small angle, then there will be no reverse circulation of the coolant.

Tip: the same method can be used when tying pellet heating boiler heating.

Diesel boiler

In this case, additional equipment is required to ensure the stable circulation of the coolant and the normal operation of the heating system:

- expansion tank;

- circulation pump - set on the return line;

- water collector - needed if the boiler is designed for heating a large area, several floors or different heating circuits.

Tip: when tying the fuel tank, take into account the installation of the fuel pump and storage tank.

It is possible to connect a solid fuel and diesel boiler in one circuit, collecting it in series. The main source of heat is solid fuel equipment, when the heating intensity of the coolant begins to decrease, the diesel heater is activated.

The latest models are equipped with all the necessary automation, so with the right settings, intervention in the operator's process will be minimal. Prior to installation, it is necessary to carry out a preliminary calculation of the equipment piping with a heat accumulator.

Conclusion

The operation of any heating system for a home or industrial facility depends on the correct strapping of the heat source, in this case the heating boiler. There are no universal schemes, so in each case it is necessary to carry out a preliminary calculation.

It is necessary to take into account the number of heating circuits, the installation of the boiler - on the floor or on the wall, as well as other factors. If you are in doubt of yourself, it is better to seek help from heating technicians. The video in the article will help you find additional information on this topic.