How to use polymer pipes for heating and their types

Are you tired of rust on metal heating pipes and waiting for the possible appearance of fistulas on their surface? Get rid of the old system and install yourself a new one - from plastic pipes. The technology is gaining popularity every year, gradually displacing metal products from apartments, private houses and enterprises. Polymer pipes for heating systems have a number of undeniable advantages, which are discussed below.

Why polymer, not metal

Let us consider this question in more detail:

| Temperature and pressure | Do not worry that the material will not be able to withstand high pressure and temperature. The technology makes it possible to operate them with a coolant heated to 95? C, which is very rare in systems of autonomous or centralized heating. The maximum pressure at the same time can reach 10 atmospheres, which is also sufficient for normal and safe operation of the equipment. |

| Resistance to mediums | The material does not react to alkalis, acids and other aggressive media. |

| Patency | The walls of products have a very low coefficient of roughness. Because of this, mineral deposits do not appear on their internal parts over time, due to which their overgrowth does not occur and the internal diameter of the passage does not change. |

| Installation | Installation in the heating system is not difficult. There are several ways to do this, including welding, fittings, glue. |

Benefits

- Polymer products are elastic, do not rot, are not deformed and do not rust.

- Their coefficient of thermal expansion is almost the same as that of metal products. That is why they are ideal for floor heating systems.

- The service life of any polymer products for more than half a century, if the temperature of the coolant does not exceed 70? C and pressure of 10 bar.

- The material is fireproof, as it does not ignite when an open flame appears.

- Transportation and installation of the installation of the heating system with their use will save up to 20% when compared to products made of galvanized steel.

- Complete absence of stray currents in the system.

- Low weight.

When making a choice, do not forget to inspect each product very carefully.

Although they have many positive qualities, there are also disadvantages:

- there are products with some roughness on the surface;

- There may be burrs on the edges of the cut. So, if you do not want to get problems during installation, pay attention to it on each product. It must be made vertically.

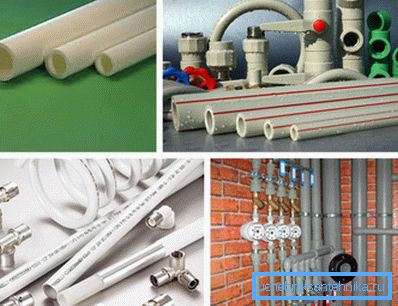

Kinds

In the construction market today are presented:

- Single-layer - only polyethylene and PVC pipes for heating. For them, it is best to use compressed polyethylene (PE-X), which after exposure to pressure becomes more heat-resistant, which makes it possible to use it in heating systems.

- Multilayer - middle layer in these products from foil. It connects to the polymer with bridges through holes in it or another type of plastic. Steel and fiberglass mesh can also be used.

Tip: Products with metal in heating systems should be used with caution, as its critical amount may cause leaks and other defects over time.

We recommend not to use products in heating systems that are initially marked as metal-plastic. This is due primarily to the fact that the different materials within them have a different coefficient of expansion.

In addition, a regular soldering iron can be used to connect single-layer ones, which will improve the mating characteristics several times, making it completely sealed.

Tip: these pipes can only be bent with the help of taps; do not bend them with your own hands, as nothing good will come of it. Only products from several layers, due to their complex structure, can bend well.

From the above, it can be concluded that single-layer polymer pipes made of compressed polymers are the best choice for heating systems. The instruction allows the use of products, reinforced mesh.

Spiral polymer pipes are also produced. They can be used in heating systems along with the rest, because during expansion they are not deformed, but only slightly lengthened, but the thickness of the walls does not change.

Compound

- For work with polymer products, a special soldering iron is purchased., the price of which is quite affordable for wide sections of buyers. It gives the opportunity to conduct them without calling specialists even to those who are not familiar with such works.

- PVC pipes for heating can also be welded, in addition, use the adhesive method of pairing, as well as bell-shaped and flanged. Each of them is not difficult.

- Welding is not used for metal products., and connections are made using fittings. Although there are exceptions:

- for pipes with a diameter of less than 40 mm, “cold welding” can be applied;

- if the diameter is larger - there are special mounting accessories.

If the work was carried out in accordance with all requirements, a high-quality weld is formed at the place of welding of the polymer pipes, which cannot be damaged. The use of simple and affordable equipment in the process of joining also emphasizes the advantages of these products over metal ones.

Conclusion

The heating system of plastic pipes is a big step forward. Now you can quickly and efficiently carry out installation, using materials and equipment that are inexpensive at the price. In fact, you can independently do what was previously required to invite experts. The video in the article will help you find additional information on this topic.