Igor kuznetsov's heating and cooking stove: basic

There is an opinion that Kuznetsov’s heating furnaces are the most efficient and cost-effective home-made heating facilities in the world. We do not know if this is true, but for a number of parameters, these units really have no analogues. Moreover, such a furnace can be assembled by hand using simple tools and relatively inexpensive building materials.

At the moment, the Kuznetsov heating furnace is widely used both in the entire post-Soviet space and in many Western European countries. Here, heating facilities originally from distant Russia are readily used as an auxiliary, and sometimes the main method of heating country houses and cottages.

So, what are the good stoves designed by Igor Kuznetsov?

Advantages of technology

Kuznetsov Igor Viktorovich invented dozens of furnaces for different purposes and with different power parameters. Among the range of developments you can find purely heating, heating and cooking and even sauna modifications.

The heating and cooking stove is most popular as it satisfies most of the needs of the owner of a country house. Such units, in addition to the traditional firebox and hob can be equipped with a fireplace, and the fireplace can be installed both in front and side or behind the stove.

In the assortment of development of heating equipment there are solutions designed for heating small construction projects, and for heating houses in two or three floors.

A modern Kuznetsov stove with a heating boiler, a hob and other options is characterized by a number of advantages, including:

- High efficiency, in comparison with other types of improvised heating devices;

- Profitability of an expenditure of energy carriers as fuel burns out with the minimum rest and practically without soot;

- Long-term heat dissipation, even after a complete burnout of the fuel;

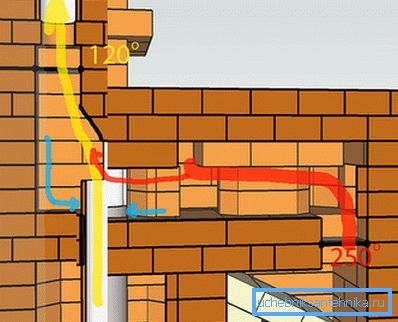

- Lack of heat loss even with an open view (heat is stored in caps);

- The uniformity of heating throughout the volume, due to the fact that the fuel gases reach almost the level of the floor;

- Uniform return of heat in comparison with traditional rotary kilns;

- Improved traction because, despite the shortened chimney, as the gases in the caps can pass the shortest way;

- There is no excess smoke, as the fuel burns out with a small amount of waste and, as a result, you do not need to clean the chimney often;

- The functionality of the application, as one oven successfully replaces the heating boiler, hob, oven, and in some cases, a flow-through water heater;

- Reasonable price in comparison with traditional brick furnaces due to economical use of building materials;

- The simplicity of the project implementation, provided that the order of the heating-cooking furnace is followed exactly;

- Attractive appearance of the structure with the right approach to the masonry work.

Selection of building material

Instructions for construction work begins with the selection of the necessary building materials. The construction will require a furnace refractory brick, fireclay brick, masonry mortar, steel corner, necessary fittings, including dampers, grates, cooking plates, etc.

The tool will require an ax, a grinder with diamond discs, a hammer with a working part not lighter than 0.5 kg, a water level, a plumb, a narrow and wide trowel, a container for diluting masonry mortar.

The quality of the masonry as well as the durability of the finished furnace depends largely on how correctly made the masonry mortar. For its preparation, dried clay without ground impurities and river sand are used.

Sand and clay are sieved before starting the preparation of the mixture in order to eliminate the presence of solid inclusions. Further, these components are dry mixed at the rate of one to one.

The mixture is mixed with water until the consistency of a very thick cream. After thorough mixing, the solution is allowed to stand for 10 minutes, then apply for the purpose.

Important: If you want to save time and effort and at the same time count on the best result, buy ready-made mixtures of red clay, which are sold in bags or by weight.

The main stages of construction

The instructions for the construction of Kuznetsov’s furnaces are multi-stage and it involves the following work:

- Foundation device - necessary because the brick structure is notable for its considerable weight and therefore requires a reliable concrete base.

Ideally, connect the foundation of the furnace with the foundation of the house during the construction phase. But this is most often not the case, and therefore around the perimeter of the building, with a projection of 0.5 meters, a platform of rubble is laid out and poured with sand-cement mortar.

- Preparation of masonry mortar (it was described earlier).

- Lay the roofing layer on the pre-prepared foundation.

- Top with a thin layer of pour clay solution to fill the roofing material.

- Then lay out the first row of bricks.. We make the laying very carefully and try to make the seams between the bricks the same thickness.

Important: If the brick is laid in its place, then we don’t touch it so as not to reduce the strength of the brickwork.

- We fix furnace equipment using special galvanized steel mounting strips.

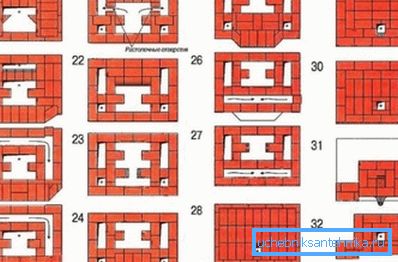

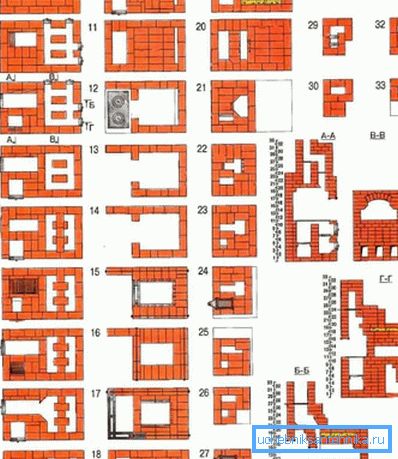

- We make the firebox lining and dry joint in accordance with the diagrams provided in the article.

- After the furnace is laid out in accordance with the proposed ordering schemes, proceed to the construction of the chimney.. In more detail about the device and ways of realization of flues for heating and cooking brick furnaces you can read in the relevant articles on our portal.

- After the oven is ready, wait a week to dry the masonry mortar, after which you can gradually heat it to speed up the drying.

Conclusion

The presence of high-quality productive solid-fuel furnace is traditionally the key to comfort in a country house. Furnaces I.V. Kuznetsova not only provide comfortable living conditions in the house, but also do it in view of an economical expenditure of fuel.

Build such a furnace with your own hands will help you ordering schemes given in the article and video, where you can find a lot of useful information.