Independent replacement of heating pipes in the apartment

Replacing heating pipes in a city apartment is an urgent problem for many owners who have decided to start a repair, because the prices for such works are far from affordable. And you are very lucky if you take from the same amount that you spend on the purchase of material. However, if you look, there is nothing particularly difficult in this work, and if desired, most people can replace the pipes themselves.

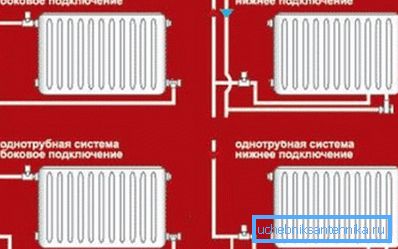

In the case where redevelopment is not required and the radiators remain in their original places, you do not even need any permits from utilities. People who have never come across this are afraid of welding. These concerns are relevant if the system is mounted from metal.

Any sane owner will be able to solder plastic pipes, as a last resort, to hire a person exclusively for soldering is much cheaper than installing the entire system.

Material selection

Everyone has the right to decide which material is more suitable for him, we just take the liberty to tell about the advantages and disadvantages of the most common materials.

Steel wiring

It so happened that the price of steel is perhaps the most democratic. Many point to the susceptibility of the material to corrosion, but if you insert a GMR into the system, such a layout will last for decades, and nothing will happen to it.

But do not rush to immediately go to the market for steel pipes, there are serious pitfalls here.

- The most significant disadvantage is the complexity of installation, on which we are trying to save. To cook such a pipe wiring with their own hands, an unprepared person simply cannot. In addition to the welding machine itself, it is necessary to possess serious professional skills that cannot be quickly mastered. Plus, you need a pipe bender and a set of dies for self-threading.

- The next obstacle could be aluminum batteries., so common in modern homes. There is nothing reprehensible in the radiators themselves, but in combination with steel they form a galvanic couple, which will invariably lead to the formation of electrocorrosion. To avoid this, it will be necessary to insert a plastic insert with a length of at least 100 mm into the system.

- To all this, you can add an impressive weight of the whole structure, which will require the installation of additional fasteners. Hang such a wiring on the drywall will not work.

Polypropylene wiring

- Polypropylene in documents is designated as PPR. If we compare this modern material with traditional steel, then the metal wins except in price and strength. All other characteristics of such wiring significantly exceed the characteristics of metal systems.

- For residents of multi-storey high-rises, the urgent problem is the rapid propagation of a sound wave through heating systems. A blow to the radiator or pipe in any apartment will be heard far beyond its borders. Polypropylene is an ideal material here, it completely dampens any sound vibrations.

- Not the last role is played by the characteristics of thermal insulation of wiring, as is well known in this segment, the greatest heat losses are observed. Given the fact that the price for heating, unfortunately, is only rising, polypropylene can save considerable amounts in the long run.

- For amateurs, assembling such a system with their own hands is the most acceptable option, but we will return to this issue later.

Important: not every polypropylene pipe is suitable for heating wiring. Structures must be designed for elevated pressure and temperature. We will not go into complex calculations, we say only that for multi-apartment buildings a pipe with the marking PN-25 is suitable.

Other types of plastic and metal-plastic

- In an effort to save money, many are trying to mount alternative types of plastic, in particular, modified polyethylene is now widely advertised in PER documents. In this case, few what ads say that the softening temperature of this material starts from 60? C, against 130? C in polypropylene.

- Such a layout is suitable only for the southern regions of our great homeland, where the heating intensity is not so high. In the middle lane, this system will last no more than 10 years. As for the northern regions, then there the modified polyethylene may not survive to the end of the heating season.

- There is still a nuance, if our Chinese friends learned how to make polypropylene well enough, then the quality of Chinese modified polyethylene leaves much to be desired. Plus metal fittings in such a system often leaks, due to increased sliveriness of polyethylene.

Tip: The letter R indicated in the marking indicates the presence of special reinforcement for the current of the hot coolant. But we should not forget that hot water pipes are not suitable for heating. Often it is this error leads to complaints.

- Metal material is good, but it is more suitable for laying underfloor heating. Installation instructions are somewhat more complicated, in particular, more specialized tools will be required. The walls of such pipes are quite thin and there is no need to talk about serious insulation. For the same reason, this layout is afraid of mechanical damage, it is easy to bend. In addition, plastic is afraid of direct sunlight.

Copper wiring

- It is no secret that in Europe most of the wiring of old houses was made of copper. But companies selling this product in the domestic market forget to mention that this layout is suitable for plumbing. Heating from copper pipes - the design is unreliable, just visit the appropriate forums, which have a lot of angry responses.

- To begin with, the price of such a layout is far from democratic, but in this case it is not the most important thing. Copper is an excellent conductor of heat, which causes large heat losses during transportation between floors.

- Modern coolant is not just water, it contains a lot of various accompanying additives that can react with copper and corrode it.

- But the most unpleasant thing is that soldering of such structures is often done with tin. Tin material is not durable and with temperature drops it is capable of cracking. As a result, such compounds eventually flow at the most inappropriate moment.

Important: in fairness, we note that there is also soldering of copper pipes with solders with a high silver content. Such joints are much more reliable, but solder is expensive, plus not every master can work with them.

Dismantling the old layout

To begin with, it should be understood that all the work of such a plan is done in the warm season, when the heating is already turned off. It would not be superfluous to contact the operating organization and clarify whether the water is drained from the system and, most importantly, whether it was completely drained.

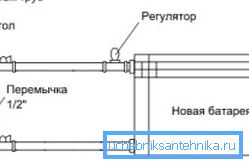

Practice shows that when starting replacement it is better to agree with neighbors on adjacent floors that the riser will dock in their apartment, interfloor overlap is a weak point and a new pipe is installed there first of all.

Trim and pull the riser is not difficult. Difficulties will begin when disconnecting wiring from old cast-iron or steel radiators. The fact is that for many years of operation, as a rule, not only shut-off valves, but also tightly threaded connections, fail.

Cast iron radiators are reliable and durable thing, but the cast iron itself is a fragile material. Therefore, do not try to unscrew with a hammer, the battery may simply burst. Now there are many liquids corroding rust, but if all efforts were useless, it is better to cut off the old pipe at a short distance from the radiator, cut the thread at the end and connect the wiring with a special adapter.

Regardless of whether you change the radiator or leave the old one, the structure must be removed. In the case of the old radiator, you need to wash it, believe me, there is enough dirt there.

And then, on the wall behind the radiator, you should glue the foil-clad screen on both sides, which will reflect the heat into the room, thereby reducing heat loss.

Tips for self-installation system

If you decide to accomplish the feat of labor and mount the wiring with your own hands, then the best option would be to replace the heating pipes with polypropylene. This is the most affordable, simple and reliable material for beginners.

Of course, you will need a special tool. First of all, it is the soldering iron itself, you should not buy it for one-time work, it is better to rent it. Of course, pipes can be cut with a hacksaw, but it is better to buy special scissors, especially since the price is reasonable.

Tip: when purchasing material, both the pipe and all related fittings are best taken from the same manufacturer. The fact is that the material from different manufacturers may differ in melting point, which would entail difficulties in soldering.

The instruction recommends installing the system in the direction from the risers to the batteries. Polypropylene does not bend, turns are made using corner fittings, so they should all have a clear angle of 90 ?. During the preparation of the sectors of the route you need to leave a tolerance at the entrance to the fitting, it is about 12 - 15 mm.

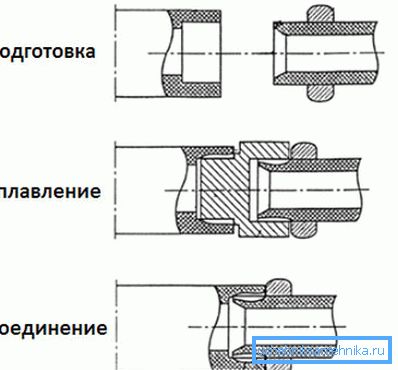

If you did not hold a soldering iron in your hands, then before you start it is better to practice. The instruction is quite simple. After the instrument is heated, the sensor signals it, on special nozzles (bits) they put a pipe and a fitting from the spirit of the parties.

Warming up time ranges from 3 to 12 seconds, depending on the diameter of the pipes. After that, you need to quickly remove the pipe and fitting, and connecting with each other, fix it motionless until it cools completely, it is about 30 - 50 seconds.

If the space does not allow you to mount the system in stages, you can assemble the wiring blocks and dock at the finishing stage.

The video shows the subtleties of mounting designs.

Conclusion

Testing the system in a private house will not be difficult, it is enough to put it under pressure and in case of a leakage a manometer will show everything within half an hour. In a city apartment it is much more difficult to wait here for the start of the heating season. But experience shows that polypropylene constructions, even mounted by an amateur, work well.