Induction heating boiler itself

The increase in the cost of energy leads homeowners with individual heating to look for savings options, in which the maximum heat can be extracted from the minimum fuel and the energy derived from it. One of the heating devices that meets these requirements is an induction boiler. This unit is powered by electricity, has a coefficient of efficiency close to one hundred percent.

The industry offers a good choice of such heating equipment, but as an economy, you can make an induction heating boiler with your own hands. In this article we will talk about the installation of an induction heating boiler.

Reasons for high performance

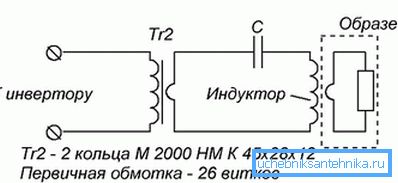

To understand why induction boilers are so efficient, you need to understand how they work. The secret is to convert electrical energy into heat energy due to magnetic induction. The most common boiler has two circuits and consists of:

- enclosures;

- core;

- primary contour;

- high-frequency inverter with smooth current control function;

- thermal and electrical insulation.

The primary circuit is a copper wire helix. It converts the energy of electricity into eddy currents, creating a magnetic field. It is the waves of this field, falling on the secondary circuit, heat the coolant. The metal wire inside the core is the secondary circuit and the heating element. The water from the return, getting into the boiler, heats up and, thanks to induction, moves to the exit from it into the heating system.

Simple option

The easiest boiler can be assembled at home, with the skills to work with a welding machine, as well as a grinder. Before making the boiler, it is necessary to prepare a metal square pipe with a size of 50 × 50 mm and a wall thickness of 2 mm. The manufacturing process, you can see in the Video section.

The dimensions of the pipe and the shape of the pipe may differ, only the thickness of the walls should not be small.

- With the help of the grinder, it is necessary to cut the profile pipe into 50 cm lengths. They will need 5–6 pieces (everything will depend on the width of the induction tile used).

- Additionally, you need to prepare two elements with a length of 25 or 30 cm (it all depends on how many sections were chosen).

- Parts of 50 cm welded together. All of them should be placed vertically. At first, they can be fixed with oven gloves, and then it is good to boil all the joints.

- For two additional blanks, you need to cut off one side to form a U-shaped profile.

- To the finished module of 5 elements, two segments are welded on the lower and upper parts with one removed wall. Their goal is to merge all the individual sections into a contour.

- Next, you must hermetically brew the formed holes on the sides.

- Insertion of the inlet and outlet is performed. They should be located diagonally, one below and the other above. You can use the pipe in? ". Two branches with threads are welded to them in order to make it easier to install into the finished heating system.

- All seams after welding are cleaned with the help of a grinder. The finished structure is degreased and painted.

- The device is mounted in the established contour. Below is supplied reverse current coolant, on top - outgoing pipe.

- In the role of the heating element serves the usual induction stove. It is necessary to acquire a plate with a possibility of adjustment of current and temperature.

- It is located behind the boiler close to its rear wall.

- The water, passing through this structure, manages to warm up. The system must have an expansion tank, as well as a forced circulation pump.

The same option can be made in a horizontal version. To do this, we need a profile tube of 20? 25 cm. Its two ends are welded with metal plugs to form a closed vessel. Two openings are cut in the upper wall, in one of them an air discharge valve is mounted, in the other, a pipe through which water will flow into the system. On the side, the return pipe cuts.

Complicate the device

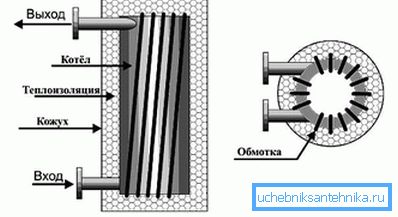

The basis of the option described below is the concept that is used in the industrial production of induction boilers. In order to assemble the finished product, we need the following components:

- metal pipe with a diameter of 160 mm and a length of 500 mm;

- metal pipe 25 mm, length 500 mm;

- epoxy resin;

- copper wire with a cross section of 2.5 mm2;

- high-frequency converter (it can be taken from an inverter welding machine or from an induction tile);

- fireproof fabric.

From the tools we will need a welding machine, grinder, chalk for marking. We do the following steps:

- The first thing you need to clog the pipe of a smaller diameter on both sides. To do this, along the entire circumference of the end face, we make cuts through 5 mm. The resulting segments bend in the middle and boil. Two semicircular or conical tips can be used instead.

- Next, fasten the tube in a larger diameter tube. It is located in the middle and attached to the expansion ribs. They can be made from scrap metal sheet. First, tacks are made to fix them, and then the joint is boiled over a distance that the electrode will reach.

- The next step will be welding the plugs on a large sleeve. Previously, they will need to make holes under the pipe in 1 "and install the threaded nipples.

- The whole structure is well cleaned and degreased.

- Epoxy resin is mixed with a hardener in the ratio of 2: 3.

- The fabric is covered with adhesive and wrapped around the pipe. After that, it should stand up to complete solidification.

- Two induction coils are made from the prepared wire. To this end, 54 turns are wound at the top and bottom. Between them, it is important to keep the same distance. After winding is complete, the entire conductor is coated with epoxy. From above it is protected by heat-resistant adhesive tape.

- Coils to the source of high-frequency voltage are connected in parallel.

- The whole structure is placed in an additional protective casing so as not to damage the conductors.

- The unit is mounted in the heating circuit. There must be a pump that will guarantee forced circulation.

The ends of a small pipe are closed in order to ensure the passage of water to the walls of a large pipe. If this is not done, the liquid will pass in the middle and will not have time to warm up.

Another option

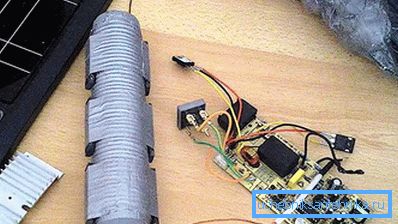

For its manufacture you will need a plastic pipe with a diameter of 63 mm and a length of 50 cm, steel wire with a diameter of 3 mm, a copper conductor with a cross section of 2.5 mm2 and a length of 11 meters.

- Steel wire is cut into 7 cm lengths. It is laid in a piece of plastic pipe.

- Two adapters are soldered into the socket on a threaded connection 1. "On both sides, coarse filters are screwed on through nipples by 1".

- Parallel textolite strips are glued to the surface of the tube.

- Coils of copper conductor are laid on them. The distance between them should be the same. After that, they are filled with epoxy resin.

- The product is mounted in the pipe of the heating system and is connected to a source of high-frequency voltage.

The number of turns, as well as the length of the conductor, will have to be chosen empirically, since the length and capacity of the system are different for each one. Steel wire, heated from inductive currents, will give the temperature of the water, which will pass through the pipe. This option can not be used as a standalone device, but it will be an excellent addition to the main source, which will save on heating fluid consumption.

Advantages and disadvantages of plastic pipe boilers

Advantages of induction boilers:

- The water in the heating system heats up twice as fast and has double heating.

- The inertia is much less than when using gas or other fuel boilers.

- Magnetic induction prevents scale formation.

- Silent work.

- No need to clean and maintain the boiler.

Like any phenomenon or construction, induction boilers have their drawbacks:

- Before use, you must make sure that the core is completely filled with water and that in the process of operation the water level should not fall, otherwise the plastic will simply melt.

- The boiler can only be used in a closed forced heating system.

- The high cost of industrial designs.

The power of the boiler must provide an adequate level of heating in the room. The most acceptable formula: 1 kW per 10 m2.

Induction boiler is a great alternative to other heating appliances. If it is possible to make it at home, the skills of working with tools and equipment assembly, the ability to install heating equipment, then you can make such a device yourself. If you are not confident in yourself, it is better to buy a ready boiler and invite experts to install it.

Video

Watch the video, which shows how you can independently make an induction electric boiler:

This video shows the manufacturing process for an induction tile boiler: