Industrial heating: analysis of the 2 most popular methods

Industrial heating is very different from the one we used to use at home. First of all, this is due to the colossal size of industrial buildings. Next, we consider the most optimal methods of heating such spacious rooms.

General provisions

Immediately it should be noted that the heating of industrial buildings using water circuits is not used at all due to its unprofitability. Circuit wiring alone will be very expensive and will significantly interfere with the installation of other communications necessary for the work of the shop equipment.

And if we take into account the high cost of operation and maintenance, then it becomes immediately clear why, until recently, the only option was just an air heating method.

Today, infrared heating of industrial premises is also widespread, and has been successfully used for thirty years by the countries of North America and Europe. We will analyze these two options in more detail.

Option number 1: air heating

Air heating device is quite simple:

| Item Name | Purpose |

| Water or steam heater | Installed in a separate specially equipped room and provides air heating |

| Manifolds and Ducts | Transport already heated air to the places to be heated. |

| Distribution heads or directional louvers | Distribute the flow of warm air flow in the room |

Benefits

- Affordable sales price of the entire system. There is relatively little metal spent on the heating pipe, and the equipment itself has an acceptable price considering the industrial scale.

- The possibility of combining with ventilation and air conditioning.

disadvantages

But the negative sides are much more significant, which in some cases makes us seriously think about an alternative to air heating.

So:

- Weak energy saving, which leads to significant waste in the operation of the system. This happens because of the elementary laws of physics, due to which the heated air rises. But the ceilings of industrial premises can rise to ten or more meters, despite the fact that the workers and the equipment requiring heating are located at a height of up to two or three meters. Thus, up to eighty percent of the building is heated in vain.

Tip: you also need to carry out high-quality thermal insulation of the roof, otherwise the heat and, consequently, cash losses will be even more significant.

- High inertia. The instruction assumes round-the-clock operation of heating devices in the winter time, since after they are turned off, it takes many hours and sometimes even knocks to restore a favorable temperature. Thus, it turns out that the system runs idle for a significant amount of time.

- Negative sanitary conditions. The collision of cold and warm streams stimulates the filling of space with dust and the spread of pathogens. As a result, there are frequent hospital among the working staff.

Option number 2: infrared heating

This option is carried out using gas or electric infrared heaters and has very significant advantages:

Merits

- Easy do-it-yourself installation. Compact devices enough to fix on any surface, send in the right direction and turn it on. In addition, installation of additional communications for the transportation of heat is not required, which significantly reduces costs.

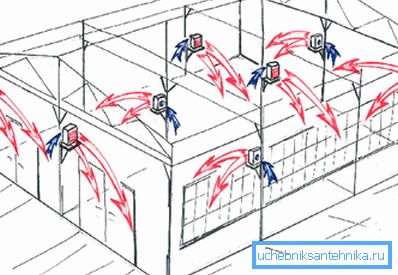

- Rational distribution of thermal energy. The equipment in question provides heating due to radiation like the sun. Thus, all the heat goes exactly where the heater is directed. The specific heating characteristic of industrial buildings does not matter, as the cost of heating the walls and air under the ceiling does not occur.

- High heating rate. There is no need to wait long until the whole room warms up, the warmth in front of the device is felt immediately.

Tip: It is recommended to place infrared heaters so that they cover only areas with people and equipment that needs heat. So you will achieve even greater energy savings.

- Creating a healthy microclimate. Here you can highlight several points:

| Positive effect | Comments |

| Heating of the lower area of the room | Heat is not at the top, as it happens in the case of air heating, but at the bottom, where people work, which is the prevention of colds |

| Lack of active circulation of air masses | Dust curls less in the air and pathogens are localized. |

| Air does not dry out | Excessive dryness is harmful to human health. |

Conclusion

Industrial buildings are distinguished by their large size, which has its effect on how they are heated. So, for example, water heating, which is popular for the residential sector, in this case will be unprofitable. But air and infrared perfectly cope with the task.

The video presents additional materials. Fuzzy industrial heating is by far the most profitable.