Infrared carbon warm floor

Infrared carbon warm floor refers to the innovative types of heating. In terms of efficiency, it surpasses any known heating systems. Its effect on the body is similar to the aeroin generator used in traditional medicine. It has been scientifically confirmed that the "rays of life", as the infrared spectrum radiation is called, contribute to the elimination of toxins from the body, inhibit stress and prevent the formation of malignant cells. Another such floor is called smart, because it heats objects, the human body, the furniture in the room, leaving the air cool. It has the ability to self-regulate: when the temperature of the heating element rises, the composite material of a carbon-fiber heated floor reduces the electrical resistance and, as a result, the power of infrared radiation decreases.

Properties and Views

In addition to efficiency (its consumption is 25–40 W / m? Per hour) and protection from overheating, the carbon floor has several other advantages:

- reliability, resistance to corrosion and fire, explosion, due to the high-tech performance and the presence of a protective layer of cement screed;

- in view of the low weight of the structure, it does not exert a load on the floor and supporting structures of the room;

- does not generate electromagnetic radiation.

There are two types of systems:

- Core mats.

- Carbon film.

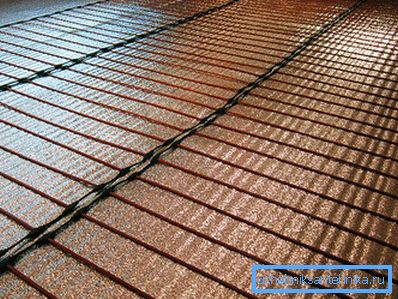

Rod thermomats are an elastic structure 83 cm wide and up to 25 m long. Each mat can be cut multiple to 10 cm. The rods are connected in an electrical circuit in parallel, therefore failure of one element will not affect the work of others.

Each rod consists of carbon, silver and graphite and is enclosed in a protective sheath of three-layer polyethylene. When electrical voltage is applied to the ends of the rod, it induces infrared waves.

The heating film of infrared film heating (IPO) consists of two polypropylene layers with a strip of carbon-graphite mixture coated on the inside of the printer.

Laying of the film, unlike rods, does not require penetration and pouring with a cement screed. Parquet, laminate or other coatings are laid over the film.

Piling and electrical connection

The technology of laying and joining underfloor heating is simple and does not require special skills. Installation steps:

- The surface before laying is leveled with a cement-sand screed and is controlled by level. Allowable irregularities are 3 mm.

- We make a waterproofing, we line the surface with a greenhouse polyethylene film 50–100 microns thick.

- Top laying insulating substrate with a reflective layer so that the heat "does not go to the floor." We use for this sheet foam materials with mylar coating: Armofol or Planex. Insulation must be laid reflective side up. The joints are fastened with adhesive tape.

- Cut and lay the strip. The length of one strip should not exceed 20–25 m. The strip should be directed to the wall with a socket from which power will be supplied. On this side, electrical jumpers are also installed, and the thermostat is mounted. We make a recess in the floor under the strip and install a thermal sensor in the corrugated tube. Suitable temperature sensor, for example, model SF-7? 30. The distance between the edges of the strips should be 5–8 mm; overlapping of strips is prohibited. It is necessary to avoid falling of tools on the surface of the film and not to step on the decomposed thermoelements of the system.

- We connect strip-sections in parallel into an electrical network using wires with clips - clips at the ends. The clamp shanks must be crimped securely at the end of the wires. Suitable wire section of 2.5 mm. It is necessary to secure the clips to the contacts of the strip. One side of it should enter between the polymer layers in the IPO, the other side of the clip is mounted on the copper bus outside. Allowed to make the connection on the bolts. Laying wires and protruding fasteners can be in grooves-grooves. We use for insulation of conductive parts thick-walled heat-shrink tubing, insulating strips included in the system and bitumen mastic.

- Connect the temperature sensor with a temperature controller. Mains power is supplied through the temperature controller. After applying the voltage, we check the operation of all sections, pay attention to the uniformity of heating and eliminate the problems.

It is important to check the contacts - the connection should not give sparking or heat more than the entire heating surface.

After that, the system can be put into operation. If you have experience in laying infrared carbon warm floor, then share your experience in the comments to the article.

Maybe you will be interested to know:

- How to lay a warm floor under the tile?

- How to make a warm floor on the balcony?

- How to choose a warm floor?

Video

In addition to the article, we invite you to view a video on the installation of carbon-fiber underfloor heating: