Installation of cast iron heating radiators: replacement,

If you believe the historians, the first cast iron batteries appeared in the late 19th century. Epochs and views have changed, new trends in fashion have replaced the outdated ones, but, nevertheless, the device of a cast-iron radiator of heating, basically remained the same. Next, we will try to figure out what caused such steady popularity and how difficult it is to install or replace such a cast-iron unit.

What is the secret of popularity

- Let's start with the fact that such units are considered perhaps the most durable. Most reputable manufacturers safely give a guarantee of 50 years. And this is fully justified, for example, in Tsarskoye Selo, a radiator, installed 110 years ago, still functions today;

Important: there is a perception that now the cast iron radiator is worse than Soviet times. This is only partly true. It all depends on the quality of the product and the manufacturer. If the battery is cast according to domestic or European GOST, then there is nothing to fear. But buying units from the Chinese or Turkish "masters", a person, in fact, takes the cat in the bag.

- Cast iron, in terms of its characteristics, is a brittle metal, but still strong enough. The working pressure for such a battery is 8 - 12 atmospheres, plus with short-term jumps or hydraulic shocks, it can withstand a load of up to 20 atmospheres. If we take into account the fact that the pressure in a city network rarely exceeds 6 to 8 atmospheres, and the average force of a hydraulic shock is 15 to 20 atmospheres, then the margin of safety is obvious;

- Such batteries are present both in the budget segment of the market and in luxury goods.. The fact is that the price of the classic MC-140 is almost the lowest. At the same time, the cost of art thick-walled casting can sometimes be several times higher than the price of a good bimetal;

- Adherents of modern materials forget about the quality of the coolant in our urban networks. This tough "cocktail" is able to disable many new-fashioned models. While cast iron is absolutely resistant to any chemical attack and neutral to corrosion, it simply does not rust;

- Due to the large diameter of the battery channels, any debris slips through it, almost without stopping, which is very important for urban high rises, with the old pipe layout;

- Iron is known to have a high heat capacity.. The battery takes temperature for a long time, but also holds it for a long time. In the event of interruptions in heating, this unit will release heat for several more hours after switching off;

- Technically, installing a cast iron radiator with your own hands is not a big deal.. If you have a tool and a couple of helpers to support, the work can be completed during the day;

- Another important advantage is the fact that components for cast-iron radiators can be found in any hardware store and the price for them is quite acceptable;

We sort of figured out the reasons for nationwide popularity.

Now let's talk about the pitfalls of these heaters:

- The first reason why many refuse to cast iron, is a serious weight of the structure. Judge for yourself, the standard section has a mass of about 7 kg, on average 7 - 10 sections are installed per room. As a result, we have from 50 to 70 kg of empty design, when filling, another 1 - 1.5 kg is added to each section. In addition to installation problems, not every wall can withstand such a unit;

- The minimum amount of coolant in a single cell is about 1l. In modern competitors, this figure is 3 - 5 times less. And as you know, the more fluid, the more energy is required to warm it up and maintain the temperature. Plus, it is very difficult to quickly regulate the temperature in such systems, due to the high inertia;

- The area of such structures, compared with modern analogues, is somewhat smaller, respectively, and the heat transfer is lower;

- Reproaches about the unattractive design are not consistent, to some extent they can be addressed to the widespread MS-140. As for figure casting, in their beauty they leave far behind the modern brethren;

Replacing and installing batteries

Tip: having decided on the type of design, it is better to start with the purchase of the batteries themselves. The fact is that such things as a plug for a cast-iron radiator, a Mayevsky faucet, suspension brackets and other accessories often come bundled with the product.

Disassembling an old radiator

If your cast-iron battery doesn’t heat up well enough, you don’t want to replace it with a new one for some reason, you can do it prevention, clean it up, rinse it, repaint it and it will last as long.

Disassembling cast iron radiators is a simple task, but it requires care.

- Initially, you should make sure that water is drained from the system, in this case you should not rely on your own knowledge, it is better to contact the mechanics. Since even in the summer without much need water can not drain;

- The instruction further instructs to disconnect the unit from the system. If there is a threaded connection, then everything is simple, took the gas key and unscrew it. In the absence of such, it is necessary to use a grinder, then remove the structure from the sheds;

- In order to make capital prevention, it is necessary to disassemble the "accordion" into sections. Directly disassembling cast iron radiators begins with unscrewing all side plugs. Here there is one nuance, so that the fragile metal does not burst, you need to preheat the plugs with a blowtorch;

- Be careful when unscrewing. The cast iron radiator thread can be left or right;

- The problem of how to determine the direction of the thread in cast iron radiators among professionals is easy to solve. On the right side of the section, the right-hand thread is cut; accordingly, on the left side there will be a left-hand thread;

Tip: since it is difficult for an amateur to determine the thread on the cast-iron radiator, especially when unscrewing the plugs, pay attention to the plugs themselves. Under the layer of paint, they must have the letter “P” or “L”. Which means right or left thread.

- After unscrewing the plugs you have access to the inside. In general, sections are connected by nipples, they resemble pieces of pipe with different types of thread at both ends. Inside the nipple there are grooves for the radiator key. The photo shows such a key and a screwdriver;

- But, as a rule, in the old batteries, the slots for the radiator key have already rusted, and even after heating, it is impossible to unscrew the nipple. Here comes the work of the usual Bulgarian, the old nipples are simply cut. After that, their remnants are sprayed with rust remover and carefully knocked out of the thread with a chisel;

- When your cast-iron "accordion" is disassembled into sections, its inside is washed with water under high pressure. The paint on top can be torn off with the help of a nozzle on a drill or a grinder with a nozzle in the form of a metal brush;

Assembly and installation of a new battery

Tip: if there are old iron pipes in the apartment, then it is better to change them immediately for plastic, and crash into the neighbors from above and below. A few meters of pipe with accessories will cost a penny, and soldering them is quite simple.

As already mentioned, the assembly of sections in such radiators is performed using nipples. Before connecting the thread should be wound sealing tape fum. Older craftsmen prefer to seal with hemp and oil paint, but skill is needed here.

The instruction is approximately as follows:

- The radiator key is inserted into the section, a nipple with a fum tape is put on it, after which both sections are connected and the nipple is screwed in;

- Do not forget to put a rubber gasket on it beforehand; it will serve as a seal between the sections;

- It is necessary to tighten with reasonable effort in order not to burst the metal.

Connecting cast iron heating radiators to the system can be side, bottom or diagonal, but whatever option you choose, it’s better to install slam-shut ball valves at the entrance and exit and mount the bypass. Thus, you will always have the opportunity to replace the radiator without shutting down the system and draining the water.

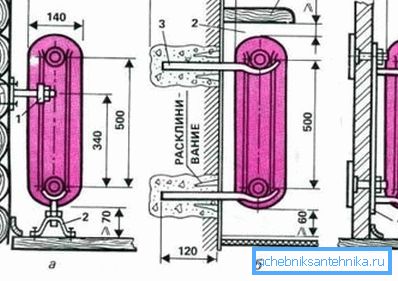

Fasteners for cast iron radiators need to take a special. If those brackets that are bundled do not suit you, then choosing from the catalog, you should pay attention only to brackets or floor racks marked “reinforced”, they are designed for the weight of cast-iron structures.

Important: on 6 - 8 sections, 1 bracket is installed at the bottom center and 2 brackets at the top. With an increase of 5 cells is added on an additional canopy at the top and bottom.

The video in this article shows the technology of installing radiators.

Conclusion

As you can see, installing a cast-iron radiator with your own hands is not the highest mathematics, and with a strong desire, such work can be done by any good owner. If the water from the system is drained, you can try, especially since you always have time to invite locksmiths.