Installation of heating boilers: what to choose

Classic stove heating is gradually becoming a thing of the past, and raising living standards requires new solutions, for example, installing a heating in a cottage will not do without a heating boiler working on a particular energy source.

This very source is probably the most important issue when choosing such a unit, because outside the city, especially in remote areas, one or other energy carriers (gas, electricity) may not always be available. We will now consider what kind of boilers can be for energy consumption, their relevance in a particular case, and in addition, we will show you a themed video clip.

Gas

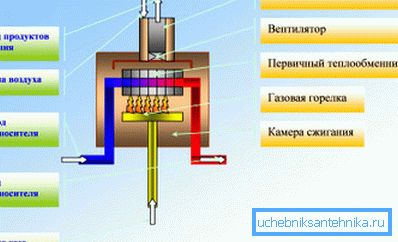

Convection boilers

If in the immediate vicinity of your suburban area passes the gas pipeline for wiring, it means you have many problems that disappear automatically - you can install the heating system of the cottage with the help of a gas boiler. The traditional convection unit runs on natural or liquefied (balloon) gas, which is fed through a pipeline to the burner, and the flame from it heats the heat exchanger.

The fluid, circulating in a closed heating circuit, is constantly at a given temperature.

The traditional installation of convector-type heating boilers is most suitable for systems with radiators, since the optimal mode of operation of such a unit is in the range of 60-80? C, which is too much for a heated floor. (See also the article Convectors of heating: features.)

The fact is that in the combustion chamber at a temperature of 55-57? C (critical point) acid condensate (a mixture of water vapor with combustion products) is formed, and this mixture destroys the walls of the heat exchanger, almost halving its operational life. Consequently, the mode of operation at temperatures below 60? C will adversely affect the service life of the unit.

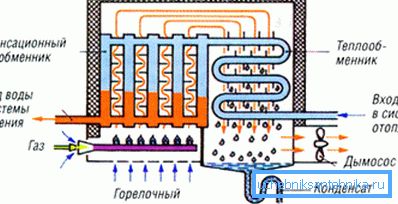

Condensing boilers

For warm water floors, they are now installing so-called low-temperature, condensing gas boilers, which in operation at 30-55? C provide the highest efficiency - up to 111%! Of course, their price is much higher than that of traditional ones, but the energy savings during operation very quickly cover all the costs of purchasing and installing equipment.

| The name of the indicator | Value for condensing boiler in% |

| Efficiency maximum | 111 |

| Loss of waste gases | 2 |

| Heat loss | one |

| Condensation loss | one |

| Total efficiency | 107 |

Average efficiency calculation for condensing boilers

Such high efficiency and efficiency of the unit are due to the fact that in traditional boilers condensate is either not formed or not used (acidic steam can reach a temperature of 150? C), and here it remains in the combustion chamber until it cools to the dew point - 55 ? C. Then, the resulting liquid is discharged into a special chamber and drained from the boiler through protective filters, that is, secondary heat is taken.

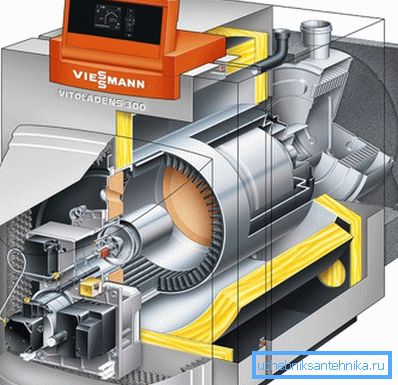

Diesel fuel

When buying a liquid-fuel unit, you should be guided by SNiP II-35–76 and joint ventures 41–104–2000 of the Russian Federation, as well as experts and practitioners who say that such equipment is most practical when there is a cast iron heat exchanger - due to its wall thickness operational resource.

In addition to heating, metal is also affected by condensate, which contains acid fumes from the combustion of liquid fuel (diesel fuel, fuel oil), which causes corrosion.

Complete with a diesel heater, two or three stage burners are supplied to which the air supply is forced, using integrated automation, but this process causes a noise effect, so these boilers are best mounted in a room separated from the house.

You may be faced with the fact that the diesel unit is sold without a burner and has to be bought separately, but in such cases it is best to invite a specialist to set it up.

Solid fuel

Note. Solid fuel boilers can operate both on coal and on firewood, including all modifications of these energy carriers. But at the same time, the units can be radically different, that is, they are ordinary, traditional boilers, as well as gas or pyrolysis boilers, developed according to the system of buleryan.

The easiest way is to install a solid fuel boiler with your own hands when it is a traditional option that does not require electrification of the room, since it is completely autonomous and works on any solid fuel, including household garbage, which you need to burn after cleaning.

But such a unit is much more functional than the usual heating furnace, since there are different dampers here that regulate the air supply to the firebox and to the blower (ashpit). This is what allows you to customize the burning function for any type of fuel.

In addition, some manufacturers produce models with several fireboxes, each of which can be designed for charcoal or coal, briquettes, firewood, sawdust, and the like. Also, the model can be provided for automatic loading, that is, the boiler itself is made with a bunker that is loaded with fuel to the string, and automatic controls its flow into the combustion chamber.

Note. Pyrolysis is the decomposition of products by thermal exposure. In this case, as a result of combustion.

Pyrolysis units are also called gas generators and for them those products are most suitable where there is the highest yield of volatile substances - pellets, briquettes, sawdust, firewood and brown coal, and some models are designed for walnut or even coke. But for all these products there is a certain threshold of humidity - no more than 20-25%, since steam interferes with the process of burning volatile substances.

The fuel is loaded into the gas generation chamber, where, with a low oxygen supply, combustion takes place slowly (smokes), and the resulting volatile substances (smoke) get into another chamber, where it burns down during forced air supply. The frequency of laying fuel depends on the design and can vary from 2 hours to several days.

And the installation of solid fuel boilers (traditional and pyrolysis) is carried out in the same way as with other types of energy carriers - in accordance with the requirements of the water circuit, with a chimney and room ventilation.

System installation with a three-way valve

- In some cases, the installation of the heating of the cottage is made with two circuits - radiator and underfloor heating, but in this case it turns out that the water supply to the system should be carried out with different temperatures - to radiators 60-80? C, and on a warm floor 30-50? C.

- To make this possible, the instruction recommends setting up the control and mixing unit on the supply pipe., which in such situations is represented as a three-way valve with automatic control.

- The essence of the arrangement is that hot water is supplied to the floor contour until the desired temperature is formed there and as soon as the coolant reaches the required degree, the valve closes in this direction and discharges the hot stream into the return pipe.

Note. For double circuits, traditional gas aggregates are commonly used. In addition, all high-temperature boilers operating on solid or liquid fuels, as well as on electricity (Tenovye and electrode) are suitable for this.

Conclusion

In any case, the installation of the heating boiler is interconnected with the knowledge of the heating system, since during installation, the fundamental criterion is to connect it to the water circuit. In addition, the manufacturer specifies its power, which should correspond to the heated room and safety requirements - ventilation, safety devices, room requirements, and so on.