Installation of heating boilers: what you should know about

As is the case with any other unit, the installation of heating boilers is carried out according to certain rules and regulations. They provide durable and safe operation of the device. The price of relevant knowledge is weighty, even if you do not install the device yourself, knowing how to do it, you can always monitor the work of the masters.

What to take into account

- First of all it should be remembered that competent installation of the heater will contribute to reliable, safe and long-lasting work of himself and the entire system as a whole..

- Note that you may later need to install additional devices, such as a column or boiler. Therefore, provide some free space in the room.

- Take into account the fact that you will need a certain area for pipe wiring connected to the boiler.

The following stages of work will be needed.

- Installing a heating boiler do it yourself.

- Installation of the heating pipeline.

- Strapping device.

- Functional check and unit start.

Regulations concerning space for the device

Your first priority will be the competent choice and arrangement of the room under the boiler room. The device must be installed in a room in which there will be enough free space, that is, there must be space around the boiler necessary for ventilation of its external surfaces.

Now about the basic norms that relate to the safe and reliable operation of the heating unit.

- The area of the boiler room should be at least 7 square meters.

- The room must be equipped with forced-air ventilation. It should be noted that the diameter of its air ducts should be 8 centimeters for every kilowatt of heat generator capacity.

- According to fire safety standards, the minimum gap from the heating boiler to the walls of the room should be 50 centimeters.

- Under the unit it is necessary to make a separate foundation. It can be lined with any of the non-burning finishing materials: floor tiles, bricks, metal sheets, etc. You can leave the foundation without finishing. In this case, the concrete screed on it must be at least 5 cm.

- All walls near the device to a height of up to two meters, it is desirable to sheathe fireproof material. For example, sheet iron.

- The diameter of the chimney must be chosen, taking into account the volume of combustion products emitted by the boiler.

Note! Observe the fire safety of the unit. It should be connected to electricity and tied, based on all Russian standards.

- The efficiency of the heat generator depends directly on the chimney device.

- Another important circumstance. If you decide to mount the heater with your own hands, without involving the specialists of the company that sold you the device, you will lose its warranty obligations for the installation and maintenance of the device.

- Based on its weight, the heating boiler can be installed either manually or using a crane. With large dimensions of the device, it is best to install it on the workplace even before the roof of the building, door and window openings are equipped.

- Before you install a heating boiler, you must accurately calculate its performance, that is, the power that should be enough for the entire building. Preliminary work

- Before assembling the heating network, it is necessary to design the boiler room, taking into account the design of the boiler, as well as plan the pipeline system configuration.

- Next, you need to make the wiring of heating pipes, not forgetting to reliably connect all network elements using soldering, fittings or welding. At the planned points should be installed boiler, expansion tank and other additional equipment.

- It should be noted that in order for all work to occur without problems, you must have the necessary tools available.

Unit installation

Installation of a solid fuel boiler is done in this way.

- Preparatory work for installation. In their course, it is necessary to fill the concrete platform (foundation) under the heating device, even if the floors in the whole house are wooden.

- Installing the device on his workplace.

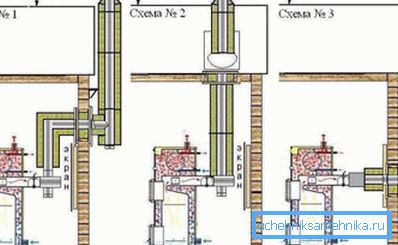

- Strapping device. It is the most difficult and crucial stage. During this process, communications are connected. This is the supply coolant to the system pipe and the analogue that returns the cooled water to the boiler.

Note! If the unit is a double-circuit, then it will be necessary to supply and return water for hot water supply. If additional equipment is installed, for example, a surge tank, then a tie should be made for it.

- Next you need to mount the chimney.

- After that, the system starts up.

Some important recommendations

Before you install a solid fuel boiler, you should take into account several important observations and suggestions of specialists.

- The efficiency of the heating unit is directly dependent on the quality of the fuel and the level of its burning.

- Warm up your house well. The lower the insulation quality, the more often it will have to restart the heat generator. The fact is that in this case, the automation will be constantly included, which is responsible for maintaining a comfortable temperature in the building, which reduces the service life of the device.

- The section of the contour pipes also affects the reliability and efficiency of the heating system. The larger their diameter, the less danger of equipment overheating and the higher the thermal inertia of the network.

When installing solid fuel boilers, a special attention should be paid to the chimney. The features of its device can have both negative and positive effects on the heat generator.

Here are the main wishes of the professionals concerning the chimney.

- The strength and direction of the winds have a strong influence on the functioning of the boiler. Based on this, select the correct length and correctly position the chimney.

- Best of all, if the ventilation channels will be without turns. If you can not do without them, then the corners do not need to do steep.

- The area of connection with the boiler and all joints of the ventilation pipes along their length must be reliably sealed. This can be done with a special compound or heat-sensitive adhesive tape.

- The cross section of the chimney should be equal to the diameter of the corresponding output of the heat generator.

Equipment check

Priority actions after installation of the unit are presented below.

- Tighten all fasteners and connections. During the inspection it is necessary to check their tightness.

- Next, the hydraulic system of the heater is washed and checked.

- If it has security automation, it should be configured based on the system features.

Before the first start-up of the unit it is necessary to carry out such actions.

- Read the instructions attached to the device. Learn how to use its governing bodies.

- Fill the heating system with water and check its tightness.

- Check that the door for cleaning the device is tightly closed.

Conclusion

Even if you do not personally install the heating boiler, you should know how to do it correctly. In this case, you can monitor the work of the masters and make sure that their actions are literate. The video in the article will continue the topic.