Installation of heating pipes by all the rules

The organization of heating in the house only at first glance seems to be a difficult task that only a specialist can handle. In fact, even if an inexperienced person performs the installation of heating pipes, then following all the rules, the output will be a durable and stable system.

Regulatory requirements

In the design of heating should be guided by the recommendations of 2 standards:

- SNiP 41-01-2003 - this document contains recommendations on the placement of heating devices in terms of fire safety. Also contains the requirements of sanitary and environmental safety;

- SNiP 2.04.05-91 - the main emphasis is placed on ensuring fire safety.

Owners of private houses with autonomous heating even at the planning stage need to pay attention to the power of the boiler. It is desirable that the system be equipped with automatic control, which will reduce / increase the temperature of the coolant depending on the temperature in the room.

Note! If automatic regulation is not provided, then it is undesirable that the total power exceeds 50 kW. This may damage the pipeline.

Of course, the installation of the heating system of polypropylene pipes in each case is different, but you can select a number of general recommendations:

- hiding the pipeline in the walls is not recommended, if their service life is less than 40 years;

- so that the coolant does not stagnate in the battery, it is not recommended to tilt more than 1?;

- It is recommended to place the pipeline with a slope, the supply section should have a slope towards the boiler, the discharge - vice versa. This is necessary to remove excess air from the heating circuit;

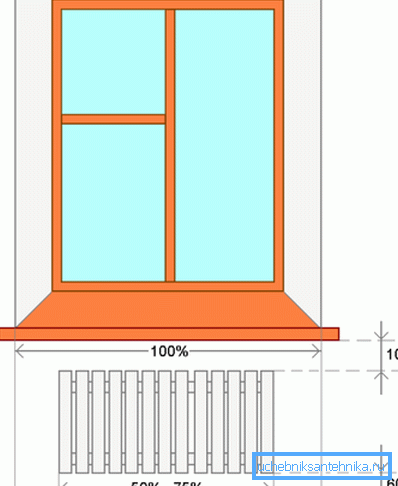

- the length of the radiator in a residential area should be approximately 50-75% of the length of the opening, in which it is installed;

- if the heater is built into the ceiling, then restrictions are imposed on the surface temperature. So, if a warm floor is used and people are constantly in the room, then the floor temperature should not exceed 25? С; if people’s stay is only periodic, then the upper limit is already 30? С. (See also the article Heat-insulated floor made of polypropylene pipes: features.)

Installation of heating in stages

To achieve the desired durability, it is necessary not only to do all the work correctly, it also affects the reliability of what kind of pipes to install the heating system. The type of coolant also greatly affects the service life, in residential buildings water is most often used, but if the working conditions are tough enough, additives affecting plastic may be added to it.

Choosing a heating scheme

At this stage, you need to decide exactly how the coolant will circulate through the house. You need to understand that the decision will affect not only the microclimate in the house, but also can significantly adjust costs.

As for the heating pipe wiring schemes, there are 3 quite popular schemes:

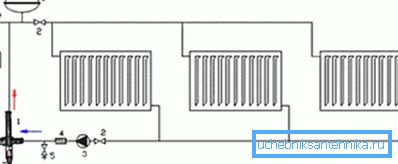

- monotube - for simplicity, it can be represented as a ring in which radiators are embedded. The coolant, entering this circuit passes through each of the batteries successively, hence the main drawback - each subsequent radiator emits less thermal energy. But the cost of the installation of heating pipes made of polypropylene in such a scheme is minimal;

Note! When organizing heating in a large room, the extreme radiators will be barely warm. So it can only be recommended for small houses.

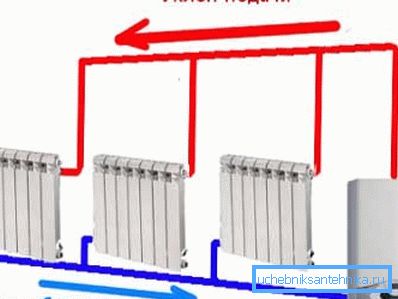

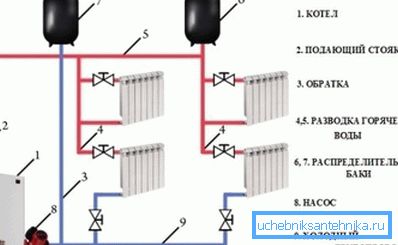

- two-pipe - 2 circuits are organized, one brings hot water to the battery, the other - removes the cooled coolant and sends it to the boiler;

- collector scheme - water from the riser flows into the collector, from which 2 pipes are directed to each radiator (one delivers the coolant, the other removes it). The main drawback can be considered a much greater length of the pipeline, respectively, and the price increases.

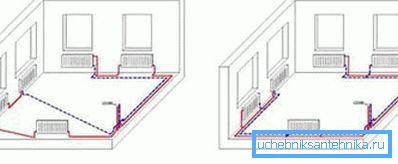

In addition, the installation scheme of heating of polypropylene pipes can be divided into systems with upper and lower spill.

The main difference between the two is the organization of the supply of coolant:

- systems with upper bottling supply coolant up the riser, and then through secondary risers, it is diluted to the radiators;

- in systems with bottom filling there is no main stand. The supply pipeline is laid at the bottom, and from it the risers part heat carrier to the radiators, that is, there is no large (main) riser.

Pipeline selection

One of the most common defects in pipelines can be considered swelling at the joints and, as a result, leakage. All this can be avoided correctly picking up the pipe.

When the question is solved, what pipes should be used to install the heating, you need to pay attention to the labeling. So, marking ПН10 means that the pipe will withstand pressure up to 10 atmospheres (wall thickness up to 8 mm), but it can be used only for cold water supply.

Other markings, for example, ПН16, ПН20 can withstand water temperatures up to 80-85? С. Nevertheless, they cannot be considered the optimal choice for the heating system. In case of leakage, repair of the heating pipe without welding will be difficult to perform.

The main reason for this is the excessive expansion of the material during heating. After the start of circulation of the coolant, the pipeline is simply deformed. That is why for heating systems a pipeline is used, reinforced with either aluminum foil or fiberglass.

The main difference of such a pipeline consists in the construction of the wall, which consists of 5 layers. The rest of the characteristics are similar - the permissible pressure reaches 25 atmospheres, and the temperature of the coolant - up to 90? С.

Features of installation of the heating system

Actually, the installation of the heating of polypropylene pipes with his own hands is that, in accordance with the scheme, the radiators are mounted and the pipeline is laid. At the same time you need not forget about the expansion tank and pump.

In general, the installation manual is as follows:

- the supply pipe is removed from the boiler and brought to the expansion tank;

- then from the tank the pipeline goes to the radiators;

- the pump can be located both at the inlet and at the outlet of the boiler;

- after installation of the feed, the discharge pipe is mounted (parallel to the feed);

- in order to close the contour, the discharge pipe cuts into the boiler.

About the cost of the heating system

You can go two ways:

- disregarding the costs, order in a specialized company the execution of all turnkey works;

- do it yourself, paying only for the material.

The advantage of the first approach is the quality and speed of work. In addition, reputable companies also provide free warranty service for the system. However, the high cost of work can scare many. The table shows the approximate cost of certain types of work:

| Name of works | Unit measured | Cost, rub |

| Radiator installation | 1 PC | 2500 |

| PP pipe layout | 1 point (gvs / svs) | min 1800 |

| Replacing the riser on the floor | one | 3500 |

Prices can hardly be called democratic. If you do the work yourself, then the approximate cost of consumables will be the answer to the question of how much it costs to install heating from polypropylene pipes.

Summarizing

Having examined in stages the installation of the heating system, it becomes obvious that this is not such a difficult task. In a short time 1-2 adults can cope with it. The reward will be not only the satisfaction of the work done, but also considerable financial savings.

The video in this article shows an example of a two-pipe heating system.