Installation of radiators. types of wiring. marking and

Independent installation of heating radiators is a very laborious process, but not very complicated. The main thing here is to follow certain rules and do everything carefully.

Types of wiring

In order for the radiator to be properly installed, it is necessary to know which type of heating pipe layout has been used. The bottom table describes these types.

| Connection type | Special features |

| Unilateral lateral | The supply pipe is connected to the upper branch pipe of the battery, the “return pipe” - to the lower analog. Such a connection contributes to the highest heat dissipation. |

| Bottom | This type of wiring is used when the heating pipes are hidden under the baseboard or floor. The supply and discharge connections are placed below, they are directed vertically to the floor. |

| Diagonal | Such a connection is optimal if the battery consists of 12 sections or more. With it, the supply pipe is connected to the upper branch pipe on one side of the radiator, and the discharge pipe is connected to the lower branch pipe on the reverse side. |

| Sequential | Used with a closed heating circuit, i.e. coolant circulates under pressure inside the network. On the devices, in order to bleed excess air, Mayevsky's taps are put. An important disadvantage of such a layout is that a breakdown or repair of the battery entails a complete shutdown of the heating system. |

| Parallel | Here the wiring is used, in which hot water is supplied through the heat pipe built into the heating network. The withdrawal is the same. Input and output valves provide the ability to repair batteries without shutting down the entire network. Minus: the devices are not heated enough if the working pressure is low. |

What will need to be considered

- When self-assembly of batteries, choose a radiator type of valves. Installation of valves on ball type radiators with an “American” is quite complicated and requires good skills.

- To connect the batteries to the network, you will need pipelines that have a thread that matches the dimensions of the pipes and pipes.

- Sleeves are wrapped around the sleeves. They are then twisted and inserted into radiators.

- Before purchasing appliances, make sure that the fixing kit for the installation of radiators corresponds to the material used to make the walls.

Note! So that the air could be blown off the batteries, they should put Mayevsky's taps on them. Some models of devices are equipped with them already at the factory.

Important rules

- Pipe sections suitable for radiators should be positioned with a slight slope in the direction of the coolant flow. If they are placed exactly horizontally, air will accumulate in the devices, which will reduce heat transfer. 1 meter of pipes should be tilted in the direction of the flow of water, at least by 5 mm.

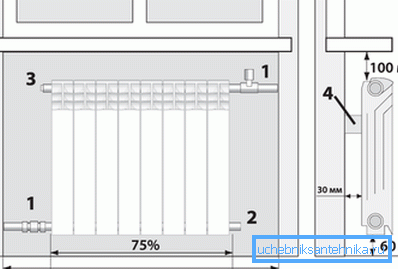

- Installing a heating radiator with your own hands should be made so that its middle axis coincides with the central axis of the window opening. Permissible deviation of up to 20 mm.

- From the floor level to the bottom of the radiator must be at least 60 mm.

- From the bottom of the window sill to the top of the device, the distance should be 50-100 mm.

- The rules for installing radiators say that the gap between the wall and the battery should be 30-50 mm.

- When installing heating devices, a prerequisite is strict observance of verticals and horizontals.

- Following the considerations of technology and aesthetics, batteries located in the same room should be placed at the same level.

Installation process

The installation of heating radiators involves a preliminary calculation of the number of their sections in each of the premises of the dwelling. Information on such calculations can be found on our website.

Marking and installation brackets

The specification of the installation of heating radiators provides that for every 5-7 sections of the battery there must be one bracket on top and one fastener on the bottom.

- Taking into account this rule, you should mark the mounting points of the holders.

- Then you need to drill holes.

- Dowels are inserted into them, into which brackets are in turn screwed.

- With proper marking, the device will rest tightly on the mounted holders and will rest firmly on them.

The subsequent installation of heating radiators with their own hands lies in connecting the devices to the pipes.

Tools and consumables

You will need a torque wrench type with dimensions. It makes it possible to strictly observe the torque moment. It is known that the pipes of the heat carrier circulates under pressure.

Note! If the joints are tight, this will result in leakage. Excessive tightening can tear the threads on the connecting elements. To prevent this from happening, modern models of radiators are completed with a passport. The instruction in it indicates, among other things, the magnitudes of the torque moments.

It will also need a sealant and plumbing sealing tape, the price of which is small.

Installation of instruments

- If the batteries are put in the course of repair, before installing them you must shut off the heating circuit and drain the coolant from it.

- First of all, the device is hung on brackets.. Further, with the help of a level, the correctness of its horizontal and vertical position is checked.

- Then from the device twisted stubs.

- If the heating system is single pipe, a valve equipped with a bypass should be connected between the battery and the pipeline.. In the case of a two-pipe circuit, only wiping with a screwed valve is used for the connection.

- The installation of biometric radiators for heating is continued by their interfacing with the help of threaded sgons with pipes. For the tightness of the joints is used seal.

Note! It should be noted one thing. Installation of steel radiators, as well as bimetallic and aluminum analogues is different in that, until the end of their installation, you should not remove the protective packaging.

Features of the installation of cast iron battery

Such radiators can hardly be called graceful. However, cast iron retains heat very well, gradually radiating it into the room.

Before installation, the radiator should be unscrewed and re-adjusted nipples, then assemble it again.

- It is best to disassemble the device on a metal workbench. It is necessary to act with two radiator keys that are inserted into the holes for the upper and lower nipples.

- To create a lever (to increase the applied force) and for reliable fixation, a metal rod or a crowbar is inserted into the ear of the tool, which fastens the lower nut.

- To stop the imbalance, both connections need to unwind at a time.

- Before work, find out the direction of the thread, it can be left and right. To understand this, you need to put the device in front of you face up. Then the left thread will be on the left, and the right on the right.

- Unscrew the nuts, remove the section. Do the same with all radiator elements.

- Then, in reverse order, assemble them into a single battery, with a pre-calculated number of sections for heating a particular room.

- After installation, the device is pressurized, if a leak occurs, the nipple is adjusted at the problem area.

Note! The brackets on the wooden walls cannot hold a mass of cast iron batteries. On this basis, devices should be equipped with floor supports.

Conclusion

Installation of heating radiators gas welding - the operation is rather complicated and expensive. For installation of devices is best to use sgony. The video in this article will illustrate the process.