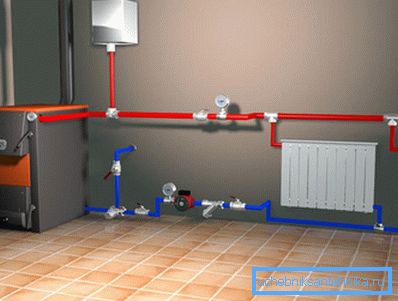

Installing a circulation pump in the heating system:

In this article we will talk about how to install a circulating pump in the heating system, without the help of qualified professionals. The topic of the article is relevant, since specialized blowers are used in most heating systems.

Despite the fact that some heating boilers are manufactured with an integrated pump, most of the boilers are still operated using remote pressure equipment.

Before we consider the features of installation, we define for a start, what are the reasons for the installation and use of circulating pumps.

The need for a circulation pump

The most common problem in the operation of heating systems in a private house is the uneven distribution of heat. When operating circuits with natural circulation, it is not uncommon for radiators to warm up in rooms remote from the boiler, while nearby batteries are already boiling (find out here how the two-pipe heating system is installed correctly).

In such cases it is necessary to take measures in order for the coolant to move more intensively through the system.

For a more uniform distribution of heat through the pipeline and batteries today, the following methods are used:

- Installation of pipes of larger diameter in comparison with what was originally installed.

Complete replacement of pipes with your own hands is an effective method that allows you to significantly increase system performance. But, deciding to use this method, you need to remember that you will need a professional calculation of the ratio of the diameter of the cross section to the length of the pipe. Moreover, the price of pipes for replacing the entire system will be considerable, and it will also take time for installation.

- Installation in the pump heating system for forced circulation of the coolant.

Installation of the circulation pump in the heating system allows you to do without replacing the pipeline and, consequently, reduces the time and material costs.

The result of the installation of this equipment will be the uniformity of temperature indicators throughout the house. Moreover, due to the intensive circulation of the coolant, it is possible to exclude the likelihood of air plugs, which has a positive effect on the service life of the heating equipment.

The principle of operation and design features

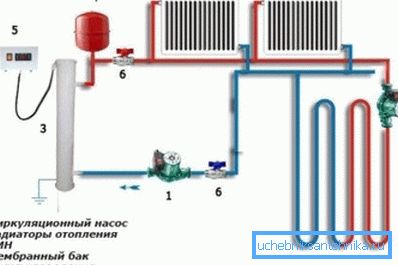

Before installing a circulating pump for heating, consider the principle of operation of this device. As already mentioned, the equipment is designed to ensure the forced circulation of the coolant in a closed system.

The design of the pump consists of an electric motor, a rotor and a shaft with an impeller. All structural elements are enclosed in a sealed metal case.

The principle of the mechanism is simple. The device is mounted in the pipeline rupture. Due to the rotation of the shaft with the impeller, the coolant is accelerated in the required direction.

As a rule, the pressure resulting from the rotation of the impeller is sufficient to effectively move the liquid medium from the boiler to the most remote point of the system and back.

Main varieties

The following types of circulation pumps are available on the market:

- Modifications of the "dry" type, in which the rotor does not come into direct contact with the coolant.

The working part of such a device is isolated from the electric motor by sealing rings made of stainless steel. When the mechanism works, the rings rotate relative to each other. Due to the pressure difference on the one and the other side of the rings, a proper degree of tightness is ensured.

Among the advantages of this solution, we note the high efficiency, reaching 80%. However, there is a significant drawback, this type of equipment is characterized by excessive noise. Therefore, installation should be carried out in a separate soundproof room.

"Dry" pumps, in turn, are of three types:

- vertical modifications with the location of the nozzles on one axis and the vertical position of the engine;

- horizontal modifications with a horizontal engine, a discharge pipe on the body and a suction pipe on the front of the shaft;

- block modifications, in which the coolant flows in the direction of the longitudinal axis and is displayed on the load radially.

- “Wet type” pumps are different from “dry” counterparts in that the impeller and rotor are in a loaded state.

In this case, the coolant acts as a coolant and lubricant. The rotor is separated from the engine by a special “glass” made of stainless steel.

Among the advantages of this device, we note a low noise level. But there is a significant drawback - the efficiency of wet pumps does not exceed 50%, which is an order of magnitude less than the indicators demonstrated by dry analogues.

Once we have decided on the choice of pumping equipment, consider how to install it.

Installation Features

At the initial stage, the calculation of the circulating pump for heating should be performed. This is done according to the following formula:

Q = N / t2-t1,

where Q is the pump capacity, t is the temperature at the outlet of the boiler, and N is the power of the heating equipment.

All these parameters can be found in the instructions attached to the selected device.

Installation instructions are simple, and therefore you will be able to cope with this task on your own without the involvement of specialists.

- Prior to installation, read the device manual and wiring diagram.

Important: Installation should be carried out with the expectation that this place has easy access.

- Drain all water from the system.

- Cut the pipe as indicated in the diagram.

- Install the pump in accordance with the instructions.

- The device is connected to a standard electrical network of 220 V.

- Upon completion of installation, the system is filled with water and excess air is withdrawn from it. After that, you can start to turn on the pump.

Important: During installation, it is advisable to bypass (bypass). Due to this bypass, the system will function in a natural way with the power off.

Conclusion

So, we looked at how and through what equipment you can make the heating system more functional and productive. It remains to purchase a suitable pump and proceed to its installation (see also the article Testing the heating system: purpose, features, procedure of work).

More useful information on this topic can be found by watching the video in this article.