Installing a gas boiler in the house itself

If you decide to heat your house with a unit that runs on natural gas, then before completing the installation work you will have to issue some documents. First of all, this is a gasification project for your home. In our country, gas supply companies give similar documentation and permission to start gas. The project indicates where the equipment should stand, as well as to what parameters the room in which the installation of the gas boiler in the house with their own hands should be performed. Designers select the type and power of the boiler. Having issued all the necessary permits and documents, and bringing the room in accordance with the project, you can buy a gas boiler and proceed to its installation.

Varieties and Purpose

There are two types of gas boilers: floor and wall (wall). More boilers are divided into chimney and beamless.

To install chimney boilers, it is necessary to install a chimney, which should be 0.5 m higher than the roof ridge. This requirement exists because natural gas combustion products are more toxic and can be poisoned. Before starting the construction of the chimney, read this section of the boiler manual and design solution.

The chimney can be made of brick, metal or asbestos cement. To prevent the formation of condensate, metal pipes are additionally warmed. The diameter of the chimney pipe must necessarily correspond to the diameter of the chimney in the boiler and have no more than three turns of the pipe.

When installing smoke-free boilers, a hole is made in the wall behind the boiler into which the gas exhaust device is mounted. From the outside, it is covered with a special fungus.

Depending on the capacity, the room in which the gas boiler is installed is selected:

- Power up to 60 kW - installation is possible in any non-residential premises of the house.

- Power up to 150 kW - installed in a specially prepared room (mini-boiler) on any floor of the house. Why are we talking about high-rise buildings? Because boilers of such power are used for heating large houses.

- Power up to 300 kW - installed in the boiler room, located on the first or basement floor.

General requirements for all rooms in which gas heating equipment is installed are:

- Ceiling height 2.5 m.

- Volume 4–15 m2.

- Door width from 80 cm.

- The presence of natural light (windows).

- The fire resistance of the room is 0.75 hours.

- At the bottom of the door should be a ventilation grille. Its value is calculated as follows: 8 cm per 1 kW of power2 lattice area.

Installation of equipment

After registration of all necessary formalities, you can buy a boiler. To simplify the installation of equipment, it is better to buy a boiler in which the supply and return pipes go in the direction of the heating system (floor model).

It is important to check if the boiler has a certificate. Local gorgas will never accept equipment that is not certified.

When everything is ready for installation, the question arises: who will install the equipment and how to install this equipment. In our country there are no strict requirements for installers. With certain knowledge, skills and tools you can do it yourself. It also saves a considerable amount of money. It is necessary to invite specialists from Gorgaz only to connect the gas and the first start-up of the boiler.

Installation of floor boiler

To begin with, it should be understood that when installing any heating equipment, it is necessary to observe technical and fire safety measures. Therefore, install a floor boiler on a solid, tough and non-combustible surface. It may be a galvanized sheet, a concrete pedestal or an asbestos sheet. The latter can be laid in the boiler room, where the tenants go quite rarely, because asbestos emits convective substances. A solid base under the boiler should be because the weight of the equipment is several tens of kilograms.

The boiler must be installed at a distance of 10 cm from the wall with a non-flammable coating. If the wall is a fire hazard, then in the area of the boiler it should be finished with non-combustible material.

After installing the boiler in place, it is necessary to level it so that there are no imbalances that may interfere with its normal operation. Then connect the equipment to the heating system. On the return pipe, before entering the boiler, a prefilter is mounted, which delays all rubbish from the plumbing system from entering the boiler. At the supply, after the boiler, a safety group, an expansion tank and a circulation pump are installed (if necessary).

Accession to the chimney is carried out by a pipe length of not more than 25 cm. All chimney connections must be reliably insulated to avoid the ingress of carbon monoxide into the house. Before connecting to the chimney it is necessary to check the draft in it.

After installation, you can invite gas workers to connect the gas to the boiler. This is done by a metal pipe on the fitting or folding connection. The same specialists check the correctness of installation and carry out the first start-up of the boiler. Then write out the act of commissioning.

You can learn more about the installation features of the floor boiler from this video:

Wall boiler installation

The sequence of work is no different from installing a floor boiler. The difference is that instead of the floor should choose a solid wall that can withstand the weight of the boiler filled with water.

The distance from the boiler to the floor is 80 cm, and the burner window should be at eye level. Thus, it turns out that the fixing bar should be set at a height of about 160 cm. It also needs to be leveled in order for the boiler to hang smoothly and work smoothly.

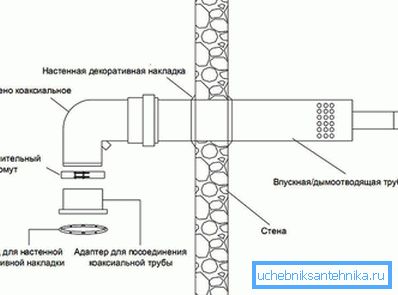

If the boiler is turbocharged, the pipe should have a slight downward slope for condensate drainage, which is formed during gas extraction. Chimney boiler attached to the chimney, as well as the floor boiler.

Before connecting the boiler to the heating system, we flush it from possible contaminants that got there during transportation. Especially if the protective caps were removed. For flushing, we connect water to one of the pipes and wait until it flows from the other outlet. Accession to the heating system is carried out depending on the location of the supply and return outputs. Do not forget about the filter, security group, expansion tank.

And, of course, the last point in the installation is set by the representatives of the gas company, who connect the gas, check the installation and make the first launch.

It is better to see once how to install the wall boiler, than to read about it many times. We invite you to watch a video about the features of installing the boiler on the wall:

Obviously, to perform these works on their own is not so difficult. But if you do not have experience with the use of tools and a clear idea of how to do the work, it is better to call the experts. Especially since you can find workers at an affordable price.

Scheme

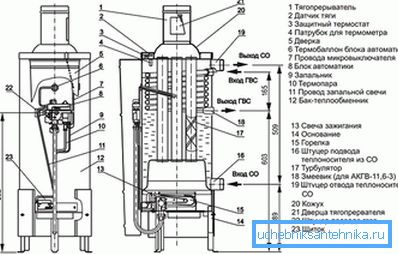

Below are diagrams of boilers, their strapping and installation of a coaxial chimney: