Is it profitable to produce heating sawdust private house

The search for alternative fuels continues to gain momentum, even for countries that are leaders in gas and oil production. In our country, ordinary sawdust may well claim this, the benefit of processing the forest remains a myriad of them. Using wood waste to heat the coolant in the heating system will not only reduce operating costs for space heating, but also provide an opportunity to recycle them effectively.

What manufacturers offer

The very idea of using garbage for heating homes is not new. At the same time, sawdust has its own peculiarity, which helps to achieve cost savings.

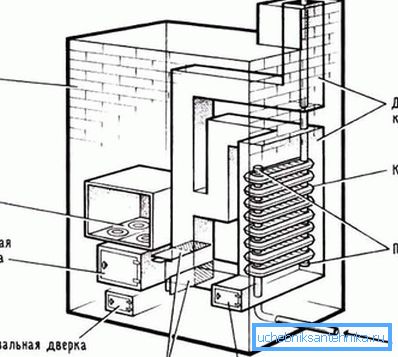

Equipment design

Heating of the heat carrier occurs in the water jacket of the boiler or furnace, for which work wood waste is used.

Most often the equipment has the following design features:

| Bottom part |

|

| Fuel chamber |

|

| Heat exchanger | It is installed in the upper part of the furnace and serves to heat the coolant. |

Modern models of wood waste boilers have an automation system, they received the addition of a “long burning device”.

It is necessary for:

- temperature control water temperature in the water jacket of the equipment;

- reduction of oxygen in the furnace;

- slow burning;

- reduce the supply of sawdust from the dispenser.

What material can be used

The process of using wood waste as fuel to heat the heating medium in the heating system is very simple - chips or chips are fed into the furnace where it ignites and burns, giving the desired temperature. At the same time, not all filings instruction permits to use for this.

The main parameters of the material are its humidity and density, they must be taken into account when choosing. From them depends on the efficiency of the boiler.

Consider the following numbers:

- the density of untreated small sawdust from the band sawmill is about 250 kg / m3. Their consumption per 1 kW of equipment capacity will be approximately 500 g / h during continuous operation;

- the density of dry porous chips from a milling machine is 100-150 kg / m3, consumption - 250 g / h per 1 kW.

Tip: the drier the material, the less necessary it is for the equipment to work effectively.

Remember that the most vulnerable point of the heating system operating on wood waste is the fuel storage area. To operate a 25 kW boiler in a not very cold winter, you need to spend about 0.5 m3 sawdust daily. To do this, you need a warehouse of impressive size or regular supply.

Tip: making a warehouse by hand, it must be carefully waterproofed. Otherwise, the effect of using cheap fuel will quickly come to zero.

Press or not

Above it was told about the use of bulk wood waste as a fuel. At the same time, today technologies that make them more compact by pressing into small briquettes are increasingly used.

Consider the characteristics of the latter in more detail:

- Pressed sawdust during combustion will produce the same amount of energy as natural wood of the same volume.

- The price of the pressed material is lower than the cost of firewood.

- To transport briquettes and store them easier, as they do not require a lot of space. As a result, loose sawdust will lose them economically. Briquettes are made most often by enterprises that recycle wood waste.

You can also independently set up the production of pressed fuel.

Below will be given tips on how to do it:

- Use industrial granulator. It should be borne in mind that the material must be of a certain density and humidity.

- For the manufacture of cylindrical pellets can be from scrap materials to make a manual press. Ready briquettes will be conveniently loaded into any fuel chamber.

- You can independently prepare a composite fuel consisting of sawdust and clay in a ratio of 10 to 1. The mixture must be filled with water, mix well and dry in the sun.

As a result of any actions proposed above, you will have compact combustible bars that emit a lot of thermal energy during combustion.

The advantages and disadvantages of wood waste heating

In fact, this is the main question that everyone who decided to use sawdust for space heating should get an answer to:

- To heat wood waste is cheap. It will be especially beneficial when a woodworking enterprise is located not far from which sawdust can be bought at a bargain price.

- The burning of wood makes it possible to quickly heat water and effectively maintain the temperature at home. The use of briquetted chips will only further enhance the efficiency of the process.

- Wood is an environmentally friendly material, so when it is disposed of, a minimum of toxins get into the atmosphere.

The operation of the plant operating on sawdust is simple. Its installation does not require a large number of permits when compared with connecting a gas heating boiler.

Of the disadvantages:

- difficulties with the storage of the material. Although the pressing partly solves this, however, it is necessary to find a fairly spacious room;

- the burning process is accompanied by the formation of large amounts of soot and ash. The latter can be used as a fertilizer, but there is no use for soot;

- clean the chimney regularly.

Conclusion

The heating boiler on sawdust can be a good solution if the fuel is located nearby or you can organize a dry and hydro-insulated warehouse of large volume for its storage. It is impossible to deny the positive effect from the use of such a method of heating homes, especially since in Europe it has been used for quite some time (see also the article Heating Boilers for Refining: Examining Prospects).

Another plus is environmental friendliness, it's nice to know that you won't leave a dirty atmosphere for children. Video in the article will provide an opportunity to find additional information on the above topic.