Low-piped double-pipe heating system - key features and

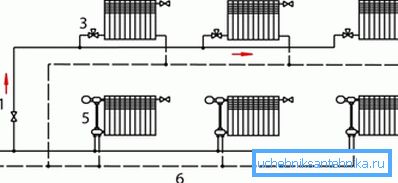

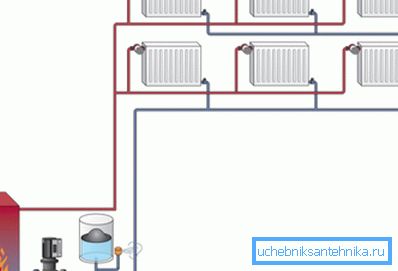

There are a lot of installation diagrams of heating communications, and sometimes it is very difficult to choose the best option, so it is important to know the main differences of some options. For example, the popular horizontal two-pipe heating system with lower wiring is best suited for single-story buildings, while for multi-storey buildings the option with vertical wiring is suitable. In this review, we consider the option with the laying of pipes in the lower part of the room.

Pros and cons of the system

First of all, we should consider the greatest advantages that the two-pipe heating system with a bottom distribution has:

| Variability | Such systems allow you to adjust different temperatures in the rooms of one house, thanks to which an optimal microclimate is maintained in each of the rooms. |

| Efficiency | When a two-pipe heating system with overhead wiring is used, the hot supply pipe is located under the ceiling - and much of the heat is consumed without benefit. The location of the highway below allows you to give heat to the room, increasing the efficiency of heating |

| Simplicity | Installation can be done with your own hands, and control is carried out from one room, where all the necessary equipment is located. As you know, the less complex the system of nodes and connections, the more reliable it is |

| The possibility of early commissioning | It is possible to start the heating system even before the completion of finishing works in the room. In addition, if repairs are being carried out on one of the floors, the heating can only be switched off there, while the rest of the rooms will be heated. |

This option has some drawbacks that should also be mentioned:

| The need for aeration | Each radiator must be equipped with a Mayevsky valve, with which it is necessary to periodically bleed air from the system. Installation of a separate air circuit helps to solve this problem, but its presence nullifies the advantages of inconspicuous pipes, since communications must be laid from above |

| Consumption of materials | Consumption of pipes when assembling communications is much greater than with the one-pipe version, the cost of the project increases accordingly. But it is worth noting the reliability and efficiency of this type, so the costs are fully justified. |

| Low pressure | Water or any other fluid moving along the supply line does not create the pressure necessary for the best efficiency. That is why it is very important to include a circulating pump in the heating system. |

Tip! It is better to choose boilers with a pump already built into the system. But in some cases, when the capacity of the system is quite large, you will need two units.

Stages of work during installation

Reliability and proper operation are largely dependent on compliance with the recommendations for the assembly of the system and quality training. Consider the most important factors.

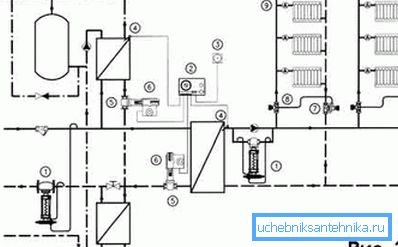

Design and preparation

At this stage it is important to correctly carry out the design work and purchase the required components:

- Determine the required heat capacity of the system in accordance with the floor space. It is very important to choose the right equipment, it is to ensure the efficiency of the system.

- Choose the optimal type of communications, for example, for single-story buildings, a two-pipe horizontal heating system with lower wiring is best suited, while buildings with two floors or more are better equipped with vertical type communications, when the coolant is supplied through the risers.

- Prepare the project, coordinate it in a specialized organization, and then approve it in an appropriate order.. This will allow to put into operation the assembled system without any problems and to carry out the work in accordance with all the norms and requirements.

- Next, you should calculate the amount of necessary materials and equipment.. This is necessary in order not to buy extra products.

Note! You should not save on the quality of materials, because in the end it can lead to system crashes. Pay special attention to the pipes for the heating system - they must withstand the required values of pressure and temperature.

The working process

Installation work should be carried out carefully and in accordance with the technology. If equipment is used for soldering or crimping, then instructions for working with the device are required to study before assembly.

It is also important to consider the following recommendations:

- The first is installed heating equipment. It is very important that the boiler is securely fixed and in the process of work does not move under the influence of vibration.

- Next radiators are mounted, they should be placed under the windows, the size and parameters are determined based on the characteristics of each room separately.

- For the installation of pipes it may be necessary to drill the walls, this issue should also be taken care of in advance. It is best to provide holes for pipes at the construction stage.

- Pipes are measured and cut right on the object, besides their reliable connection with radiators and other nodes it is very important to attach them to the walls. This is done with the help of special fastening clips.

Conclusion

This option of communications allows you to get rid of pipes under the ceiling, the system is almost imperceptible, which is a great advantage when finishing. In addition, heat is consumed more efficiently. In order to understand the question even better, watch the video, in it some of the important nuances of the work are explained in more detail.