Mixing knots for a heat-insulated floor: device and mission

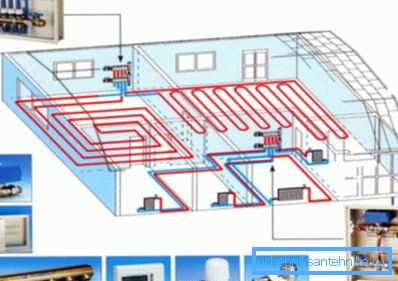

Floor heating system is an excellent addition to radiator heating. However, unlike traditional batteries, it belongs to low-temperature heating devices, therefore when using these systems together, the mixing nodes of the heated floor are necessarily installed. Below we take a closer look at what these devices are, what elements they consist of and what functions they perform.

Why use a mixing unit

To understand why you need a mixer for a water heated floor, first of all you need to figure out how the system works, which we will do below. So, for radiators and underfloor heating the same heat carrier is supplied. Moreover, it warmed up to the maximum, i.e. to a temperature that is required for radiators (up to 95 degrees).

At the same time, the temperature of the floor surface according to sanitary standards should not exceed 30-31 degrees, otherwise it will be uncomfortable to walk on this floor. For this reason, the temperature of the coolant, which is fed into the circuit, is, depending on the thickness of the screed and the type of floor covering, - 35-55 degrees.

From this it follows that water cannot be supplied directly from the boiler to the circuit, since its temperature may exceed the permissible limit. Just, for the purpose of its lowering, a thermo-mixer is applied for a warm floor. It mixes the hot coolant with the colder one, i.e. return line

Note! If the heating of a house or apartment is implemented using low-temperature circuits, the mixing units are not installed, since in this case there is no point in using them.

Device mixing node

Conventionally, the work of the mixer under consideration can be described as follows:

- The hot coolant is supplied to the heating collector and there rests against the mixing valve for a heated floor with a thermostat.

- If the temperature of the coolant is lower than the required one, the valve is activated, as a result of which the supply of the hot coolant opens.

- As soon as the temperature reaches the desired value as a result of mixing hot and cold liquids, the valve cuts off the flow of hot liquid.

I must say that the mixing group for a heated floor is needed not only to adjust the temperature, but also to circulate the coolant in the heating system circuit. Therefore, the system consists of the following basic elements:

| Mixing (safety) valve | Designed to be mixed into the hot liquid circuit. |

| Circulation pump | It provides the movement of fluid in the circuit with a certain speed. This ensures uniform heating of the entire floor area. |

In addition to these two main elements, the system can also be:

- Bypass - protects the mixing unit from overloads.

- Shut-off and drain valves.

- Air vent.

It should be noted that the mixing heat exchanger must be installed before the circuit, however, the very place of its installation may be different:

- In the room where the system is implemented warm floor.

- In the boiler room.

- In the near collector box.

Types of mixing units

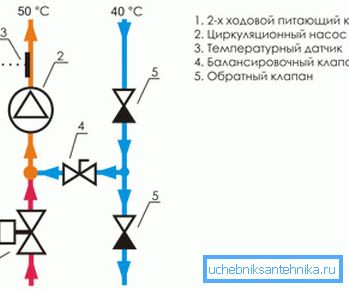

The main difference in the operation of thermomixers is in the design of distribution valves. The most common are two-way and three-way devices. Below is a detailed look at their features.

Two way valve

Two-way valves are also called feeding. On this device a thermostatic head is installed, which contains a liquid sensor responsible for monitoring the temperature in the coolant, which enters the circuit of the heating system.

The mixing of the coolant is carried out according to the principle described above, i.e. the return flow is continuously supplied, and the hot liquid only when necessary.

Among the advantages of this design are:

- The system never overheats, which increases its service life.

- The valve has an insignificant flow capacity, which ensures smooth temperature control, i.e. without sudden changes.

For these reasons, most of the specialists, when mounting the mixer for a warm floor with their own hands, use two-way valves.

Three Way Mixer

This device combines two functions:

- Bypass Feed Valve.

- Balancing bypass valve.

Its main feature is that it mixes a cold return line and a hot heat carrier. Often, three-way valves are equipped with actuators to control weather-dependent and thermostatic devices.

It is believed that the three-way mixers are universal and indispensable in large systems, as well as in systems where weather-dependent controllers are used.

However, they have some disadvantages:

- It is not excluded the possibility of supplying to the contour of a warm floor by a signal from a thermostat of a hot heat carrier with a temperature of 95 degrees Celsius. This may result in pipe damage due to overpressure. In addition, sudden changes in temperature shorten the life of the system.

- Even a minimal change in the device settings can lead to a significant change in the temperature in the circuit, which is associated with a large bandwidth of the device.

Note! The durability of the system depends on the build quality of the mixing unit and the quality of the selected materials. Therefore, these points need to be given special attention at the stage of the system design.

Features of equipment installation

There are quite a few options for connecting equipment. Below is the most popular scheme of the mixing site underfloor heating.

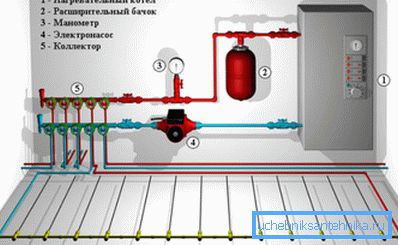

It allows you to assemble the system yourself by connecting all the important elements in sequence:

- Boiler;

- Distribution node;

- Pipeline.

Before mounting the distribution unit, you must install a protective metal cabinet, which can be open or closed. In some cases, the node is mounted completely open, i.e. in the form of a stand. In this case, access to it is simplified, but connection protection suffers.

The place for the cabinet, as a rule, is chosen depending on the location of the circuits. If several branches are used, it is advisable to install the cabinet in the middle, at the same distance from the contours and close to the main pipes. Such a “middle” location provides the best hydraulic performance.

It is better to start assembling with your own hands with the installation of a thermometer and shut-off valves, which should be located at all outlets of the circuits. Most often, parts for adjusting the operation of feed and return flow are supplied in a set of collector kit.

Focusing on the scheme, it is possible to correctly and fairly quickly install the distribution node, connect the supply and discharge pipes to it, and also ensure that one or more circuits can be shut off, which may be required during the operation of the system.

The parts are connected using compressor fittings, the installation kit, which includes:

- Nuts;

- Bushings;

- Ring clips.

Tip! For mounting the system it is better to use brass fittings, despite the fact that their price is higher. This is due to the fact that on their inner walls almost no scale accumulates.

In cases where the diameter of the parts does not match, adapters are used.

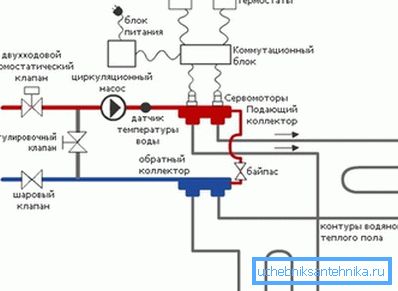

The brief assembly instructions are as follows:

- First of all, two pipes are connected to the distribution unit - coolant supply and return flow.

- Then connect the contour elements.

- Then the system elements are installed in the following sequence:

- circulation pump;

- air outlet;

- drain cock;

- three-way mixer.

This system allows you to fully control the heating process.

Note! The operation of the described system is completely dependent on the heating boiler - lowering the temperature or limiting the flow of coolant leads to a decrease in the temperature of the heated floor.

Here, in fact, all the basic elements of the installation of distribution nodes.

Conclusion

Mixing units are a necessary element for heating systems that combine traditional radiators with a warm floor. Moreover, the durability of the heated floor depends on the quality of the distributor. Therefore, the quality of its installation should be given no less attention than the laying of the warm floor.

From the video in this article, you can learn some additional information on this topic.