Modern heating from polypropylene do it yourself for an

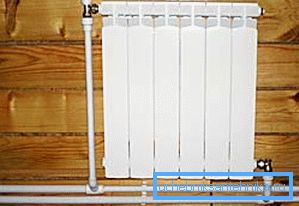

The introduction of new materials for working with plumbing devices allows you to learn a new profession to people who previously would never have decided on such experiments. With the help of polypropylene pipes and a special soldering iron, it became possible to make heating in an apartment or a private house without involving professional teams. At the same time, welds in terms of reliability are no worse than those of specialists. Today we will tell how to make heating from polypropylene in your house.

Advantages of polypropylene pipes

Before choosing metalplastic or polypropylene for heating, we suggest to learn about the advantages of the latter over other materials:

- Not afraid of corrosion.

- It has a low thermal conductivity, what provides only small losses of temperature of the heat carrier.

- The inner surface remains perfectly smooth throughout its life., therefore, there are no deposits on it like on metal pipes.

- The price of the material is one of the lowest., Therefore, pipelines are much cheaper than metal and metal-plastic pipes.

- Polypropylene does not react to any aggressive media..

- The material has a certain plasticity coefficient., that allows you to make bends in the path of the thermal line.

- Polypropylene heating withstands rapid changes in the temperature of the coolant.

- Due to the high sound insulation properties, the movement of water through the pipes occurs almost without sound.

Tip: Installing pipes made of polypropylene, you will know that in the case of freezing of the coolant in the system, the pipe does not burst, but stretches.

- Long service life, easy installation by hand.

When buying a material, we recommend carefully studying the markings on the pipe, as they are produced not only for heating, but also for cold water supply.

Advice: give preference to proven brands and suppliers that have long been proven in the market.

Choosing polypropylene or metal-plastic, please note that in the second case, you have component fittings will be much more expensive, and they will not be able to withstand the same heat transfer pressure as polypropylene ones.

Preparation for work

Before you install polypropylene for heating, you must first prepare:

- a special tool - a soldering iron with nozzles, with which the main work will be done;

- measuring tape for measuring elements of the pipeline;

- bracket;

- marker;

- merilonovo heater;

- fixture for fixing the pipeline to the wall;

- polypropylene pipes;

- scissors for cutting plastic (you can buy or rent);

- Couplings lkz nhe ,, corners and adapters.

Choosing a heating system

From propylene can be collected as an open or hidden heating scheme. Consider how to mount each one of them:

| Hidden |

|

| Open |

|

Recommendations of specialists

With self-repair advice of professionals can play a significant role.

Let's find out some of the nuances of arranging a polypropylene heating system:

- Solder the pipes better with an assistant, especially when you do this work for the first time.

- Ensure that the temperature of the ambient air during soldering work is above + 5 ° C. Otherwise, a thermal zone will form around the soldering.

- Practice on low-cost clutches before starting your main job. As a result, you can solder the pipes without overheating their surface.

- After heating, secure the immobility of the connection by fixing it for 10-15 s.

Tip: when replacing old metal pipes with polypropylene pipes, it is necessary to use a table of correspondences of pipe diameters of various manufacturing. Do not forget to take into account the ratio of pressure and temperature of the coolant in the system.

- Connect to the radiators from the main entry pipe O20 with a thickness of 3.4 mm, which is similar to the metal-O16 with a thickness of 2 mm.

Process

Below is a step-by-step instruction on installation work:

- Carry out a preliminary calculation of the flow and return gasket if the two-pipe version is used.

- Calculate the length of the segments for each section.

- Specify the types of pipe fittings.

- Determine by the reference book according to the diameters of the products used, the welding time of the joints and their cooling.

- Work with the elements of the system begin after they warm up to the temperature set in the room for soldering, so that the plastic does not crack.

- Measure according to the calculation of the footage of the products and apply a cutting point with a marker.

- Take a special scissors and make a perpendicular even cut.

- Wipe both edges before working with an alcohol solution, and remove the dirt with a dry cloth.

- Install a pre-degreased tip that matches the diameter of the section on the soldering unit. Install it horizontally and heat to 260 ° C.

- Place the prepared fittings and pipes into the heater holes, observing the horizontal position.

- Select the time according to the table and heat the elements.

- Pull out the parts carefully, insert the pipe into the fitting and firmly hold the necessary time.

Tip: Do not twist the connected parts until they are completely cool. Then the soldering can provide a high level of reliability.

During operation, polypropylene pipes may sag because of the hot coolant circulating through them. Therefore, it is necessary to fix them to the wall every 300-500 mm with the help of clips.