Multi-fuel boilers: the main types and features of operation

In this article we will talk about what constitutes a multi-fuel heating boiler, how it differs from conventional modifications and what are the features of its operation.

Multi-fuel, or as it is also called, the universal boiler differs from conventional analogues by the ability to work with different types of fuel. This solution allows you to use the fuel that is currently available.

A typical example is heating in areas remote from the gas distribution main. It is likely that after a while the gas will be supplied, but it is necessary to sink because now.

Therefore, people build their own wood stoves. But, with the advent of the possibility of connecting to the gas pipeline, a gas boiler is acquired, as being more profitable and easy to operate.

As a result, twice as much money is spent than if the gas boiler had been originally purchased. In order to minimize the waste of money, time and effort, you can purchase a universal heating boiler from the very beginning.

Construction features

Instructions for the use of heating equipment depends largely on the type of burner installed. The design of the burners in the oil and gas units differ slightly. So why not unify the burners and make them omnivorous?

As a result, the following types of heating installations appeared on the market:

- modifications on the natural and liquefied gas;

- modifications on gas and liquid fuels;

- modifications on solid fuel in combination with gas and diesel fuel;

- modifications on solid fuels, electricity, gas and / or diesel fuel.

Listed assortment is more than enough for the arrangement of any country houses and cottages.

Important: When constructing autonomous heating systems in urban apartments, combined boilers did not receive particular popularity for a number of obvious reasons.

Consider what the range of equipment on the market.

Natural and liquefied gas

In the event that it is not possible to connect the heating equipment to the gas distribution pipeline, it is not at all necessary to use units running on wood or diesel fuel.

A number of modern boilers in the main mode are designed to work with natural gas. But after a minor change of settings, you can use liquefied gas in special cylinders as fuel.

Among the advantages of this solution, we note the following:

- compact dimensions of the equipment;

- possibility of wall mounting;

- the price is not much higher than the cost of conventional gas heating boilers;

- affordable cost of both natural and liquefied gas;

- no need to license the system when using liquefied gas;

- possibility of automation of the heating system and operation in conjunction with the systems "Smart Home".

Natural / LPG & Diesel

These units combine the two extremes, namely, the cheapest and most expensive fuel. Therefore, such modifications today are reasonably considered the most promising and cost-effective.

As already mentioned, the equipment operating on gas and diesel, differs only in the type of burner, and this difference is not so significant. Therefore, on the market you can buy universal units that run on both types of fuel already in the factory version.

Important: Any qualified specialist working with heating equipment, if necessary, can make a gas boiler liquid fuel. Performing such a task by changing the number of operational settings and minor replacement of a number of parts.

Natural / liquefied gas, diesel and solid fuels

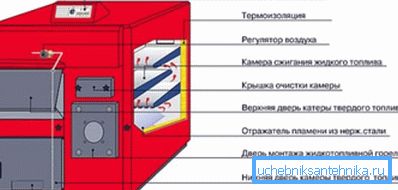

Units that combine the ability to work with the above fuels appeared relatively recently. As a rule, these are massive installations with a floor layout.

Impressive sizes are largely due to the presence of a traditional firebox designed for burning wood, coal, pressed briquettes or pellets, sawdust, etc. Gas and diesel burners take up less space, as they are attached equipment.

Despite the use of three different sources of heat in these boilers, one or two (by the number of circuits) heat exchangers are used.

Among the advantages of such devices, we note the following:

- high degree of universality, as in the combustion chamber it is possible to burn various types of solid fuel, starting with firewood and ending with coke, and besides this there is a gas and diesel burner;

- ease of use and maintenance services;

- the possibility of exploitation both in the volatile and in the non-volatile mode.

However, the disadvantages of such devices are much more than advantages:

- high price compared to the cost of traditional gas boilers;

- the need to arrange a special boiler room, as these universal boilers are massive and large;

- the boiler room will have to be equipped with a concrete base, since the ordinary floor can not withstand the weight of the unit;

- minimal ability to automate workflow and control security;

- lower efficiency and lower power compared to full gas or liquid fuel equipment.

Comparing the listed advantages and disadvantages, we can assume that such boilers are a good solution for arranging heating systems in the country or in small cottages. After all, it is in the country that there is always a certain amount of firewood and other fuel remaining during the cleaning of the garden.

Natural / liquefied gas, diesel, solid fuel and electricity

It turns out that there are such units, and these devices are manufactured in the factory. Such boilers, by the ratio of advantages and disadvantages, are similar to the previous category of devices.

But in this case, the installation uses heating elements, which affects the increase in the dimensions of the device. In addition, due to the large number of equipment, these units are difficult to operate, maintain and repair.

Conclusion

So, now you know what a multi-fuel heating boiler is, and what are the features of its operation. Should I buy such equipment or stop the choice on traditional units?

The answer to this question should be based on the characteristics of the house, personal preferences and budget allocated for the implementation of the heating system. More useful information can be found by watching the video in this article.