Oven heating of a private house: how to improve the

The modern market of climate systems is replete with various thermal equipment, which operates on any type of energy carriers. But the good old wood stove has not been forgotten, because if you make some changes to the standard design, it can warm a dwelling that is large enough in area. This article describes how to make stove heating in your home more efficient and cheaper.

Features stove heating

Classic stove heating at home - when using a Russian stove or a fireplace - heats the indoor air unevenly. Directly near the heated structure, the temperature is above everything, and as it moves away from it, the air becomes colder.

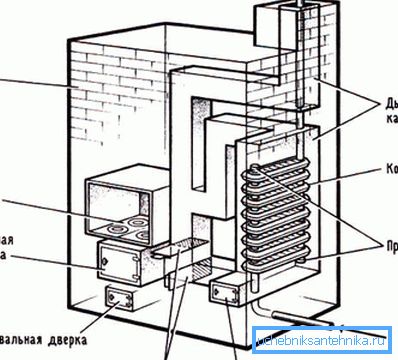

Therefore, engineers working in the design of climate systems, was invented a special heating circuit - a heat exchanger mounted in the combustion chamber or on the chimney, inside which circulates the coolant. After heating, the liquid is distributed through pre-laid pipes through radiators, heating not only the room where the stove is installed, but also the rest of the rooms in the house.

Simply put, the stove in this case acts as a conventional heating boiler, which is part of the classic water heating system. However, unlike the latter, it is able to heat not only the coolant, but also the air in the room (as a classic design).

The advantage of such a system is that the layout of a house with stove heating can be any, because the pipes are laid according to an arbitrary scheme (especially in systems with forced circulation of coolant).

There are two main types of heat exchange registers, the features of which are reflected in the table.

| Variety | Description |

| From pipes | It is used in furnaces on which it is supposed to prepare subsequently in food. A hob is easily mounted above such a heat exchanger. Tubular registers of heating can be made of round or shaped parts (the latter is more convenient). Choose pipes with a sufficiently large cross section (more than 35 mm) and thick walls. Then the fluid will warm up more efficiently, and the heat exchanger will last longer. |

| Sheet steel | It is made of metal sheets with a thickness of at least 3 mm (for a coal furnace - at least 5 mm). The minus of the system is that it is difficult to install a stove above such a heating register (it will not heat up well). Plus - the possibility of flexible sizing, higher efficiency and service life. |

Tip! If you equip the stove with a stove, then the fuel (wood or coal) will be as economical and efficient as possible, since the thermal energy released during combustion serves two purposes at once.

Furnace heating with water registers and batteries is most common in rural areas, where there is no main gas, and power lines will not withstand the load from the installed electric boiler. As for heaters on diesel or coal, the furnace bypasses them much in terms of efficiency, since in this case also the thermal energy of the exiting combustion products is used.

The main disadvantage of installing a heat exchanger in the furnace of a wood or coal stove is a significant reduction in the volume of the combustion chamber. That is, you will either have to put firewood more often, or buy a special firebox that provides long-term fuel burning.

If you plan to design stove heating in a private house, where people are not expected to live year-round, you should regularly drain the heat carrier from pipes and radiators or choose another heating scheme.

Independent installation

Laying a new furnace

Any scheme of furnace heating of a private house, which is obvious from the very name, requires a stone wood-burning heating stove, in which the heat exchange register is installed.

The question can be solved in two ways:

- Installing the heat exchanger in the existing structure in the house. You need to choose a device that fits to the existing furnace or order a heat exchanger of the desired size in a specialized workshop (the price in this case will be higher). If you have experience with the welding machine, you can weld the structure yourself.

- Laying a new furnace with their own hands. This is a more time-consuming method, but you can more accurately find the dimensions of the water register and furnace, ensuring sufficient power of the climate network and maintaining the normal size of the combustion chamber of the fuel.

Note! When buying a water heat exchanger or ordering it in a specialized workshop, you need to ensure that the thickness of the water layer is at least 3 cm. Otherwise, if the fluid circulation rate through the pipes is insufficient, water may boil.

It is necessary to pay attention to the thickness of the steel from which the walls of the heat exchanger are made. They must be at least 5 mm, otherwise the design will quickly burn through. Remember, coal gives a higher flame temperature and requires a more durable water register, and if you plan to use firewood, you can stop at less massive varieties.

Let us dwell on some of the nuances of the design of the stove, which must be observed so that the house with stove heating warms up more efficiently, and the climate network you designed lasts longer:

- To avoid destruction of the furnace, a gap should be provided between the heat exchanger and the walls of the structure.

Its size depends on the material of the heat exchanger used:

- from metal pipes for heating - from 10 to 15 mm;

- from sheet steel - from 5 to 10 mm.

You also need to remember that over time, this technological is clogged with combustion products, soot and fuel residues. As a result, the efficiency of the heating system drops significantly, and the furnace itself may collapse. To avoid this, it is recommended to provide a small door or valve for cleaning.

- You can install a water heat exchanger is not in the combustion chamber of the fuel, and on the pipes that bring hot smoke to the outside. Many qualified stove experts advise taking this scheme as a basis. When using it, firewood or coal placed in the firebox burns more economically, and the heat energy of hot gases is used more efficiently.

Installing a heat exchanger in the finished oven

This option requires an accurately sized water heating register.

You can install it using two basic schemes:

- Without disassembling the plate. This method is used for furnaces equipped with a steel or cast-iron cooking surface that can be easily dismantled without destroying the main structure.

Note! Install the heating circuit, completely avoiding disassembling the furnace, will not succeed. It is necessary to remove a few bricks or stones to bring out the inlet and outlet of the heating register.

- With partial disassembly of the furnace. Here you will need to disassemble the stove to the base of the fuel chamber (it is usually built into the grate, providing air access). After installing the heat exchange unit, the structure is restored to its original form.

When upgrading the furnace, you can change the configuration of the smoke channels. But you need to ensure that the normal thrust is maintained, otherwise your alteration will lead to smoke in the room and release of combustion products into the room.

Designing the rest of the heating system

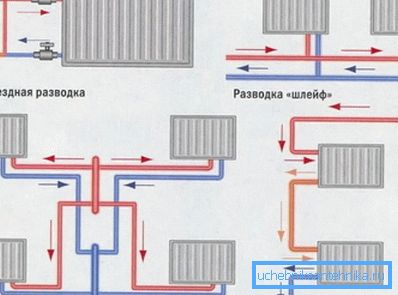

Pipes and heating radiators in the house are mounted according to the classical scheme. For more efficient heating of all rooms, it is recommended to use a two-pipe layout. In this case, even the most distant room will receive its share of heat.

The greatest effect can be achieved by installing a circulation pump. So the fluid through the pipes will circulate more intensively, which will warn her boiling in the heat exchanger.

Conclusion

Stove heating is an excellent choice for private houses located in rural areas where there is no main gas. They are an excellent alternative to liquid and solid fuel boilers.

However, if you want to heat a very large house, an oven (even with a water register) will not be enough. It is necessary to use other types of climatic equipment. You can learn more about this from the video posted in this article.