Paint for radiators: choice, features of heat-resistant

The final stage of the installation of a new heating system made of metal pipes and batteries or redecoration is their protection and finishing with paintwork materials. In this case, it is very important to know whether the water-dispersion paint is suitable for radiators or it is better to use acrylic compositions. If you are plagued by doubts, be sure to read this article.

Heat resistant paint

With a wide range of paints and varnishes to choose the right mixture for batteries is not so easy. The question of what paint to paint radiators of heating is very important, since all the nodes of the heating system have to work in high temperature mode, then the process of applying paintwork materials should be carried out with heat-resistant compositions.

The main requirements that paint for a radiator of heating and supply pipelines must meet are as follows:

- Maintain a heating temperature of the order of 80-90 degrees.

- To be resistant to temperature changes.

- Do not contain inclusions aggressive to metals, in order to avoid rapid deterioration of heating devices and highways.

- Do not release substances harmful to the environment and human health when heated.

- Must be durable, that is, reliably protect surfaces from corrosion without losing its original appearance as long as possible.

Only radiator paint with all these qualities will be able to retain its protective and decorative properties until subsequent repair.

Note! Paint and varnish products that are not designed for surface treatment, working with permanent heating, on radiators quickly crack and turn yellow.

Almost in every type (by quality composition) of paints a niche is allocated for covering radiators.

Alkyd formulations

Alkyd compounds are characterized by a number of positive qualities:

- Very good resistance to high temperatures.

- Coating uniformity.

- Mechanical resistance (abrasion).

- A wide palette of colors and shades.

- Long service life.

The disadvantages of this type of paints can be attributed to a sharp, unpleasant smell, accompanying drying and the possibility of tarnishing over time.

Tip! Performed a few days before checking in or before leaving for vacation coloring of radiators will not cause any special aromatic trouble.

Acrylic and acrylate formulations

Such materials are made on the basis of organic solvents, therefore, when working with them, it gives off an unpleasant odor that dissipates very quickly.

On the surface of a metal battery or pipe, acrylic compounds form a very strong and dense film resembling a polymer.

Such coatings:

- Dry quickly.

- The most durable.

- Have a glossy surface.

- Easy and simple to wash.

There are acrylic compositions for the treatment of water-based heating systems, the so-called acrylate. Such paints have practically no characteristic odor, but otherwise possess all the excellent properties of the acrylic series of paintwork materials.

Water dispersion formulations

Perhaps this option is the most popular and preferred among buyers, this is due to the fact that it has such advantages as:

- It lies down evenly.

- Practically no odor, which makes it possible to use without restrictions.

- It has the shortest drying time.

- Not dangerous in application with unprotected hands.

The main thing when buying paint to protect against corrosion and decorating the heating system to ensure that it is suitable for this purpose.

Attention! As a rule, on the packaging with similar products there is a “radiator paint” mark: directly under the name or marking, or in the “instructions for use” section.

Hammer effect enamels

One of the varieties of alkyd paints is quite interesting hammer enamels, creating an unusual pattern on the treated surface.

Depending on the pigment added to the enamel, it can be imitation:

- Coinage.

- Hammer blows.

- Other effects.

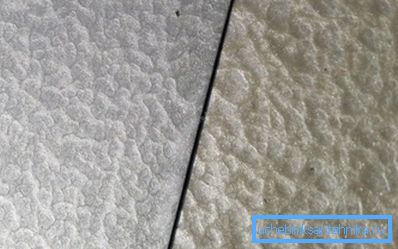

Such paint is indispensable for cast-iron radiators with their uneven, rough surface. Heterogeneous coloring visually successfully veils all the irregularities and defects in cast iron heating devices.

Tip! If you wish to treat a smooth surface with a hammer enamel, for a better effect, it should be roughened, for example, with a coarse sanding cloth.

The rest of the workflow with similar compositions is performed in the same way as with others:

- Surface preparation;

- Cleaning of repaired surfaces:

- Rust removal with inhibitor (rust converter).

- Scraping old paint.

- Degreasing.

Next, the selected paint for cast-iron radiators with their own hands is applied to the prepared surface.

Powder coating

A very effective modern method of dyeing with dry powder paints is rarely used in everyday life because of the complexity and high cost. The price of a special spray gun for uniform application of powder paints reaches $ 50.

In the factory, aluminum and bimetallic radiators are painted in this way.

The calculation of the required amount of paint

Another important point before buying paint for the heating system is to correctly calculate the color of the radiators.

Do not be alarmed, the procedure is not complicated, but you need to have background information:

- The area of the painted surface.

- The consumption of a specific paint per one square meter of battery.

Note! The standard paint consumption for radiators of a certain brand will be prompted by the accompanying recommendations indicated directly on the product packaging.

Now let's learn how to calculate the total color of cast iron radiators and supply lines:

- To calculate the area of round pipes, you can use the well-known formula for the length of a circle L = 2¶D, where ¶-3.1415 ...; D-diameter of a circle (pipe). Knowing the length of all pipes to be painted and their diameters, calculate the area of pipe coloring.

- For such calculations with heating devices you will need to know the number of sections in each and the color area of one section. For us, the area of one section of a particular battery has already been calculated by their manufacturers. So it remains only to find this information in the documentation for the device and multiply this figure by the total number of sections.

For example, let's calculate the area of coloring of radiators MS 140 M-500-0.9 consisting of 10 sections:

- The section of such a radiator has the following geometrical parameters:

- Height - 588 mm.

- Length -93 mm.

- The area of painting is 0.24 m2.

- Accordingly, the device of ten sections has a painting area of 10 * 0.24 = 2.4 m 2.

- Further, the calculated area is multiplied by the standard consumption of the selected paint and the total is obtained for the radiators.

- Add to it the estimated amount of paint on the pipe and find out the volume of the necessary purchases.

As you can see, nothing complicated is a similar calculation for a piping system.

Conclusion

By choosing the right paint and following all the rules for preparing surfaces and painting them, you can get a high-quality and beautiful coating of radiators for quite a long time. Just insert a small remark that acrylic paint for heating radiators, that water dispersion is not as effective in production areas as powder formulations.

Pick up materials to fit your needs! In the presented video in this article you will find additional information on this topic.